Retractable recovery barrel

A recycling bucket and shrinking technology, used in trash cans, garbage collection, household appliances, etc., can solve the problems of low efficiency in removing parts, many residual parts, and inability to meet the requirements of factory use, achieving good results and increasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

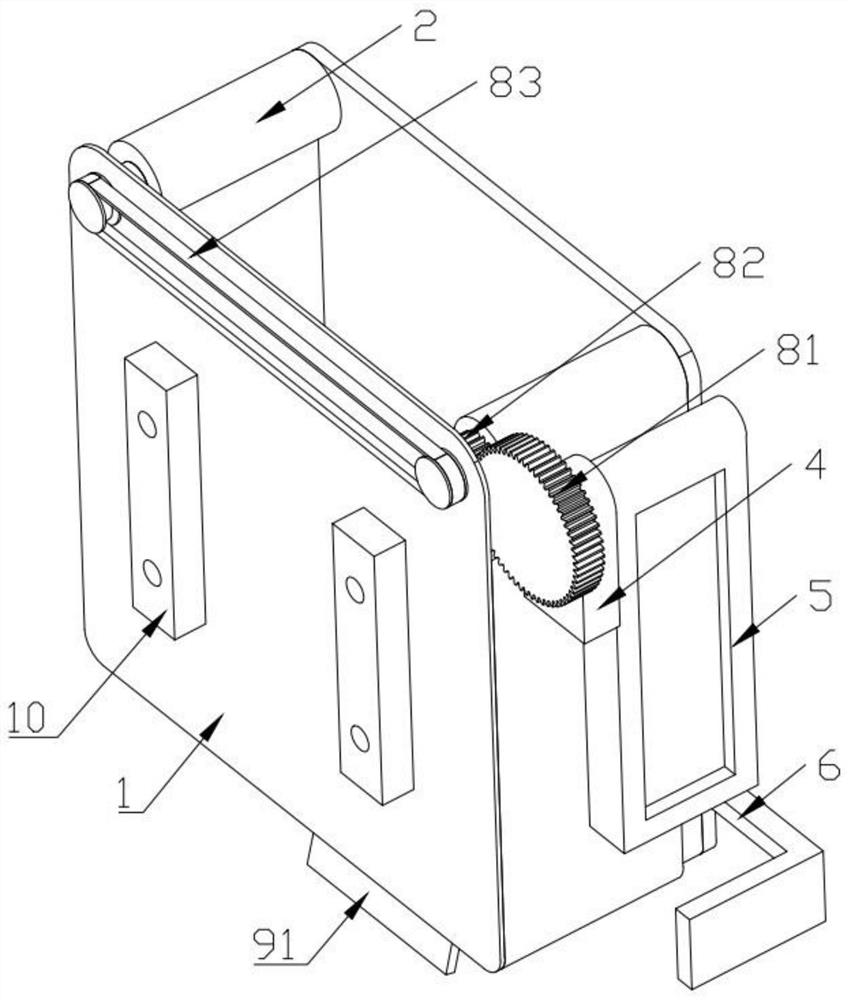

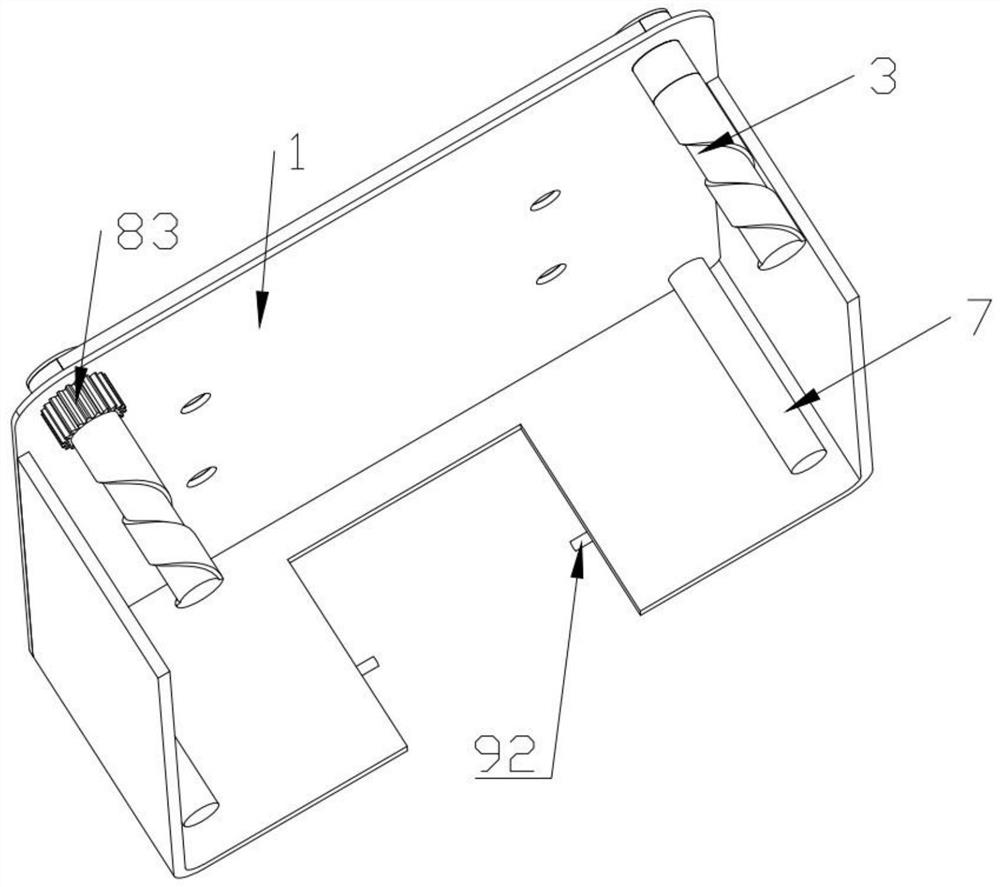

[0018] Such as Figure 1-5 As shown, the present invention provides a retractable recovery barrel, which includes a fixed shell 1, a moving shell 2, a screw rod 3, a guide rod 7, a transmission device, a connecting block 4, a driving plate 5, a locking block 6 and a sliding plate mechanism, The fixed shell 1 and the movable shell 2 form a recovery barrel structure, the slide plate mechanism is arranged at the bottom of the fixed shell 1 and the movable shell 2, two screw rods 3 are respectively connected to the two sides of the upper end of the fixed shell 1, and two guide rods 7 are respectively fixed On both sides of the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com