Low-temperature safety valve performance test system and test method

A test system and safety valve technology, which is applied in the field of low temperature safety valve performance test system, can solve the problems that cannot be independently controlled, the test process cannot be controlled, and cannot meet the test requirements of low temperature and high pressure and high temperature and low pressure, and achieve the effect of saving cold sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

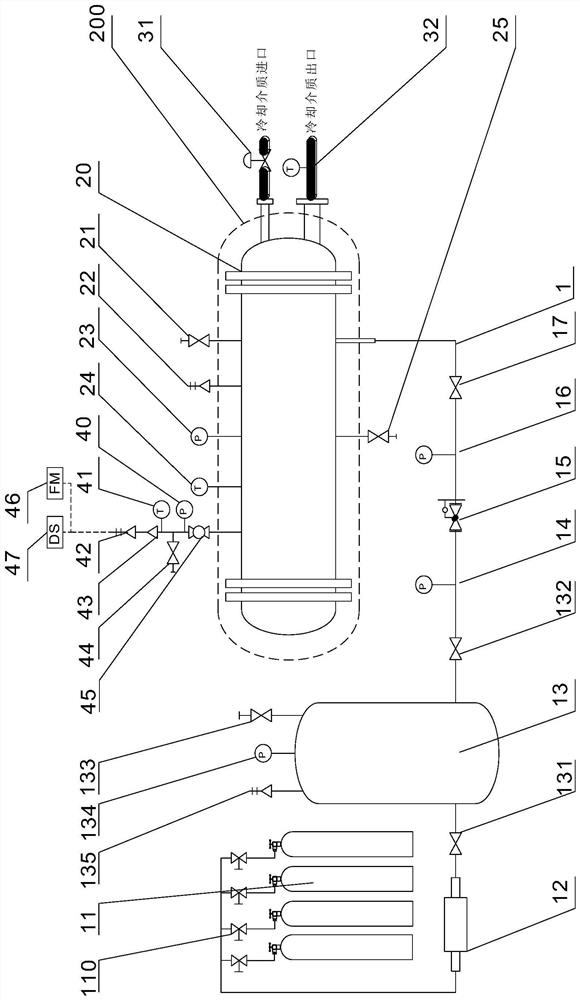

[0043] Use the test method of a kind of cryogenic safety valve performance test system described in embodiment 1, setting test comprises the following steps in the described performance test:

[0044] S1, system purge; sequentially open the heat exchanger exhaust valve 21, the shell side intake valve 17 on the shell side of the heat exchanger 20, the storage tank outlet valve 132 in the pressure regulating assembly, the storage tank intake valve 131, Gas cylinder valve 110, adjust the opening degree of the test medium flow regulating valve 15, ensure that the test medium input pipeline, the shell side of the heat exchanger, and the atmosphere are in a conduction state, start the booster pump 12, and the test medium supply module supplies air to the system at this time, After the set time, stop the air supply of the test medium supply module, and close the heat exchanger exhaust valve 21;

[0045] S2. Provide high-pressure test medium environment and perform precooling operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com