Supporting mechanism of vacuum heat insulation vertical storage tank

A technology of vertical storage tanks and supporting mechanisms, applied in the directions of containers, packaging, transportation and packaging, to achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0018] A support mechanism for a vacuum-insulated vertical storage tank, comprising: a hoop support unit and a top support unit;

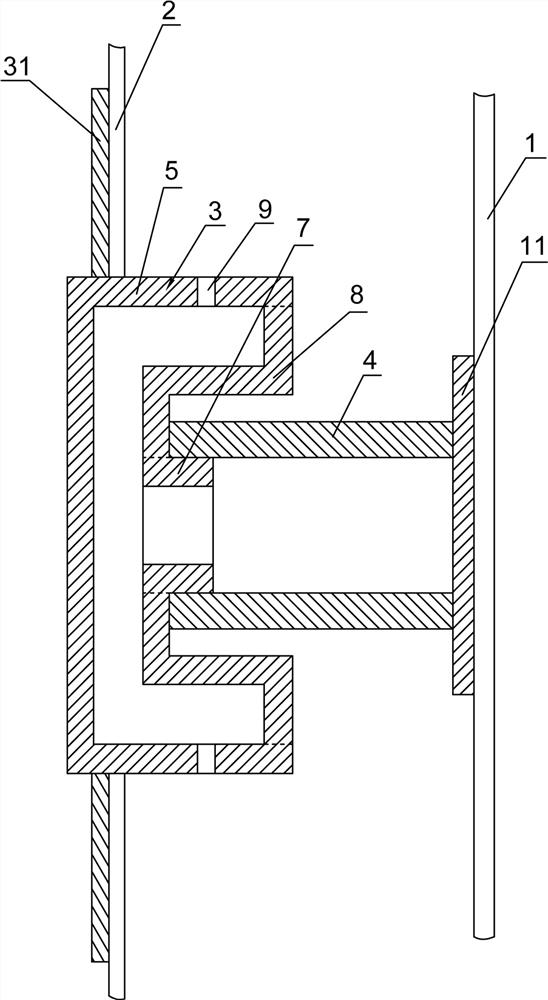

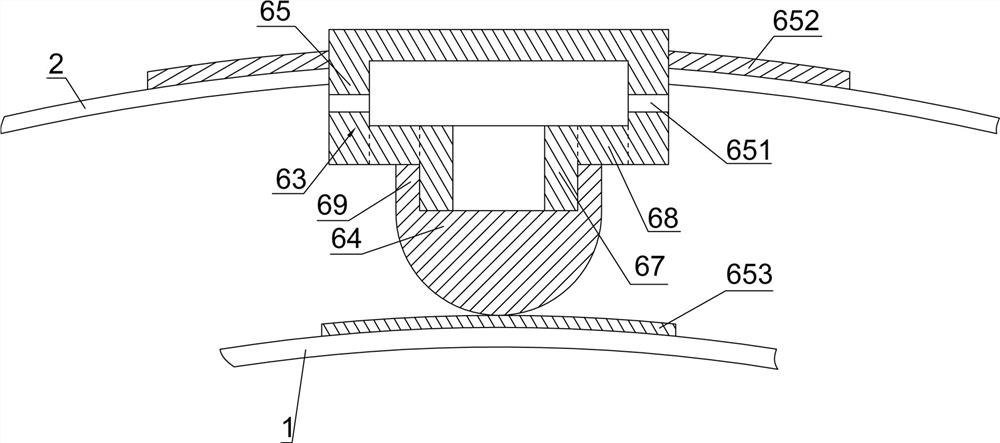

[0019] Such as figure 1 As shown, the structure of the hoop support unit includes: a hoop support seat 3 arranged between the side walls of the inner and outer cylinders 1 and 2, the hoop support seat 3 is fixed to the side wall of the outer cylinder 2, and A fiberglass branch pipe 4 that can support the inner cylinder 1 from the ring direction is arranged on the supporting base 3. The thermal conductivity of glass fiber reinforced plastics is low. The structure of the supporting base 3 includes: piercing on the side wall of the outer cylinder 2 The side fixed pipe 5 is sealed and welded to the side wall of the outer cylinder 2, the outer port of the side fixed pipe 5 is sealed by a sealing plate, and a side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com