Harvesting and sowing integrated compound operation machine

A working machine and duplex technology, applied in the fields of harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of increasing the number of agricultural machinery rolling, strengthening the degree of soil compaction, increasing the operating cost, etc. The degree of hardening and the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

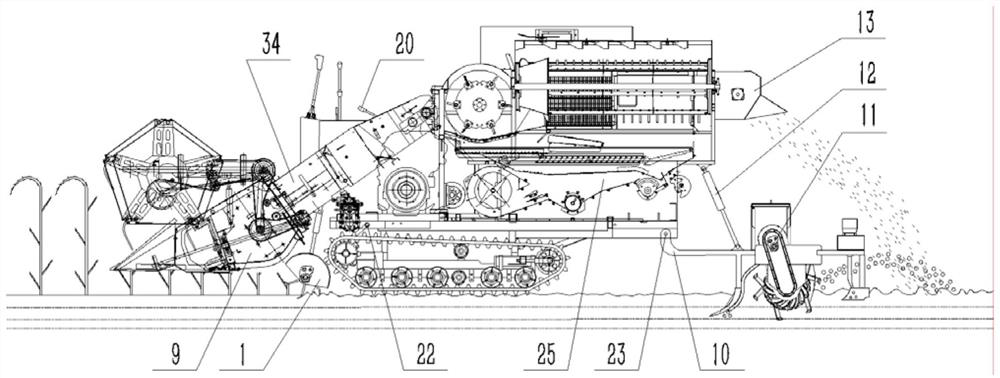

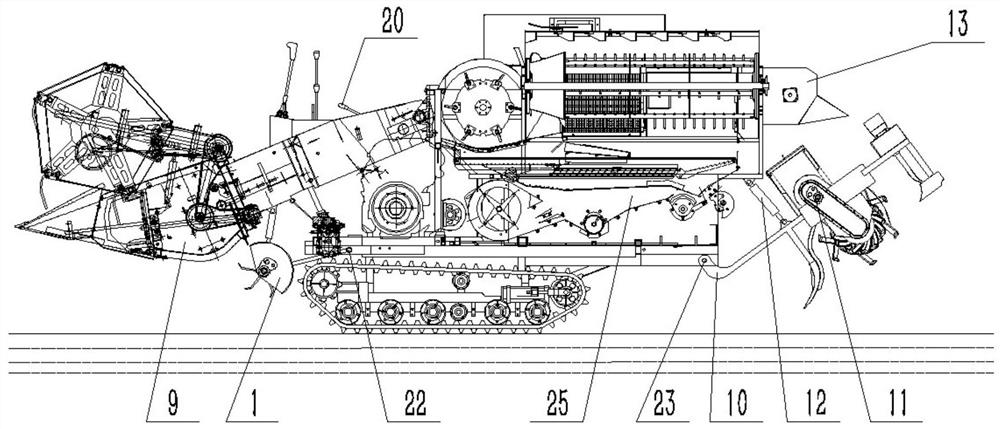

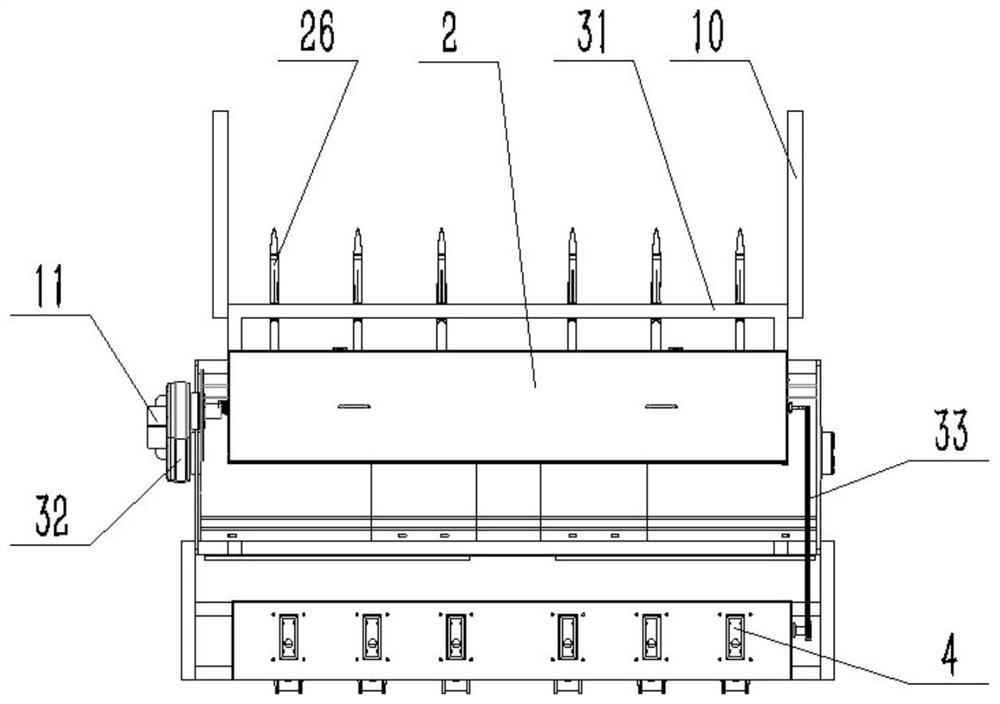

[0031] Such as Figure 1-6 As shown, a harvesting and sowing integrated compound operation machine includes a combine harvester 25, a stubble removal device 1, a shallow loosening device 31, a fertilization device 2, a rotary tillage ditching device 3, a seeding device 4, a detection device, and a first driving device , the second driving device and the control device.

[0032] Preferably according to the present embodiment, the combine harvester 25 is a rice combine harvester; the stubble removal device 1 is installed in front of the chassis of the combine harvester 25, and the stubble removal device 1 is connected with the conveying trough 34 and the chassis of the combine harvester 25 respectively ; The first driving device is used to drive the stubble removing device 1 to work.

[0033] The shallow loosening device 31, fertilization device 2, rotary tillage ditching device 3 and seeding device 4 are sequentially installed on the frame 10 connected to the rear of the chass...

Embodiment 2

[0046] The main difference between Embodiment 2 and Embodiment 1 is that the combine harvester 25 is a wheat combine harvester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com