A heating element detection system, method, device and storage medium

A heating element and detection system technology, applied in the direction of test/monitoring control system, general control system, control/regulation system, etc., can solve the problems of affecting production progress, inaccurate detection and judgment of heating element failure, frequent operation, etc., to achieve Guaranteed production progress, realized automatic fault detection, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

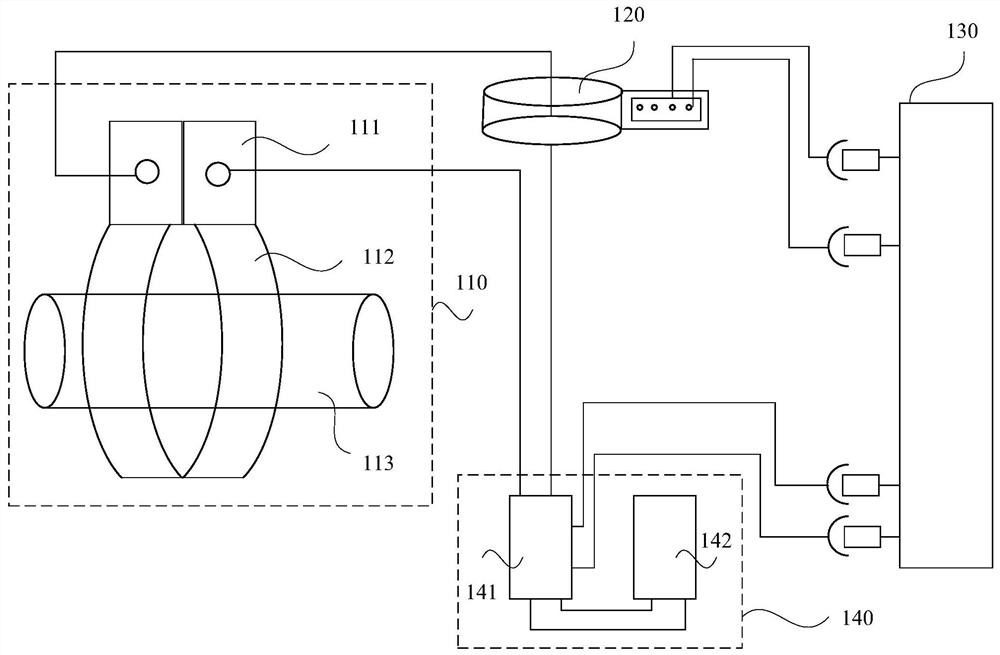

[0040] figure 1 It is a schematic structural diagram of a heating element detection system provided in Embodiment 1 of the present invention. This embodiment is applicable to the automatic detection of heating element failures based on PID control. The specific structure of the heating element detection system includes:

[0041] Element heating module 110, current transformer 120, PLC control module 130 and heating power supply control module 140; said element heating module 110 is electrically connected with said current transformer 120 and said heating power supply control module 130 respectively, and said PLC controls The module 130 is electrically connected to the current transformer 120 and the heating power control module 140 respectively;

[0042] The heating power supply control module 140 is configured to provide power to the element heating module 110 according to the received heating start signal output by the PLC control module 130 after the PLC control module 130 ...

Embodiment 2

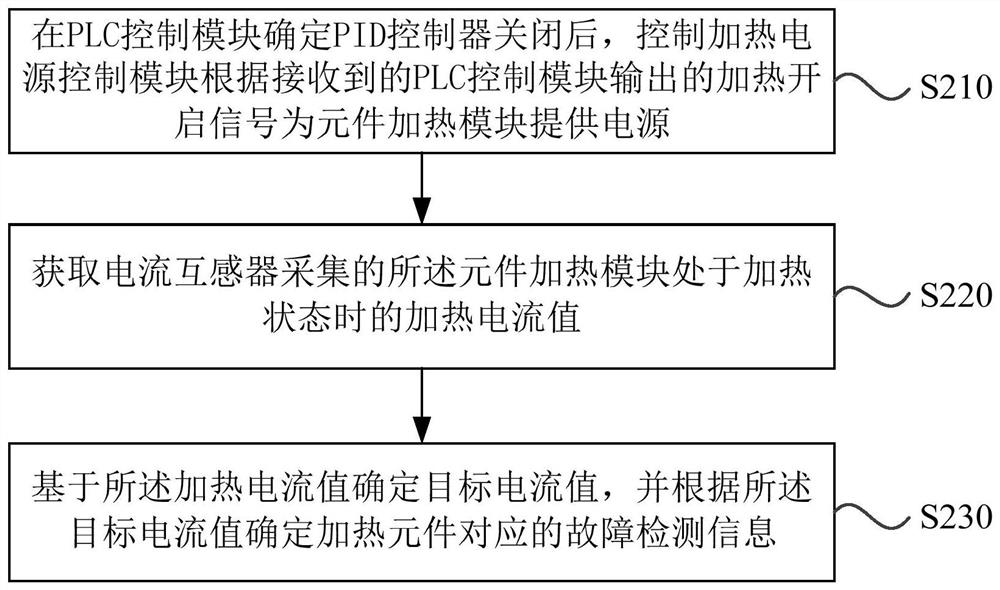

[0071] figure 2 It is a schematic flowchart of a heating element detection method provided in Embodiment 2 of the present invention. This embodiment is applicable to the situation of automatic detection of heating element failure based on PID control.

[0072] Correspondingly, the method in this embodiment specifically includes:

[0073] S210. After the PLC control module determines that the PID controller is off, control the heating power supply control module to provide power to the element heating module according to the received heating start signal output by the PLC control module.

[0074] On the basis of the above-described embodiments, after the PLC control module determines that the PID controller is closed, the control heating power supply control module provides power for the element heating module according to the received heating start signal output by the PLC control module, including: determining in the PLC control module After the PID controller closes the p...

Embodiment 3

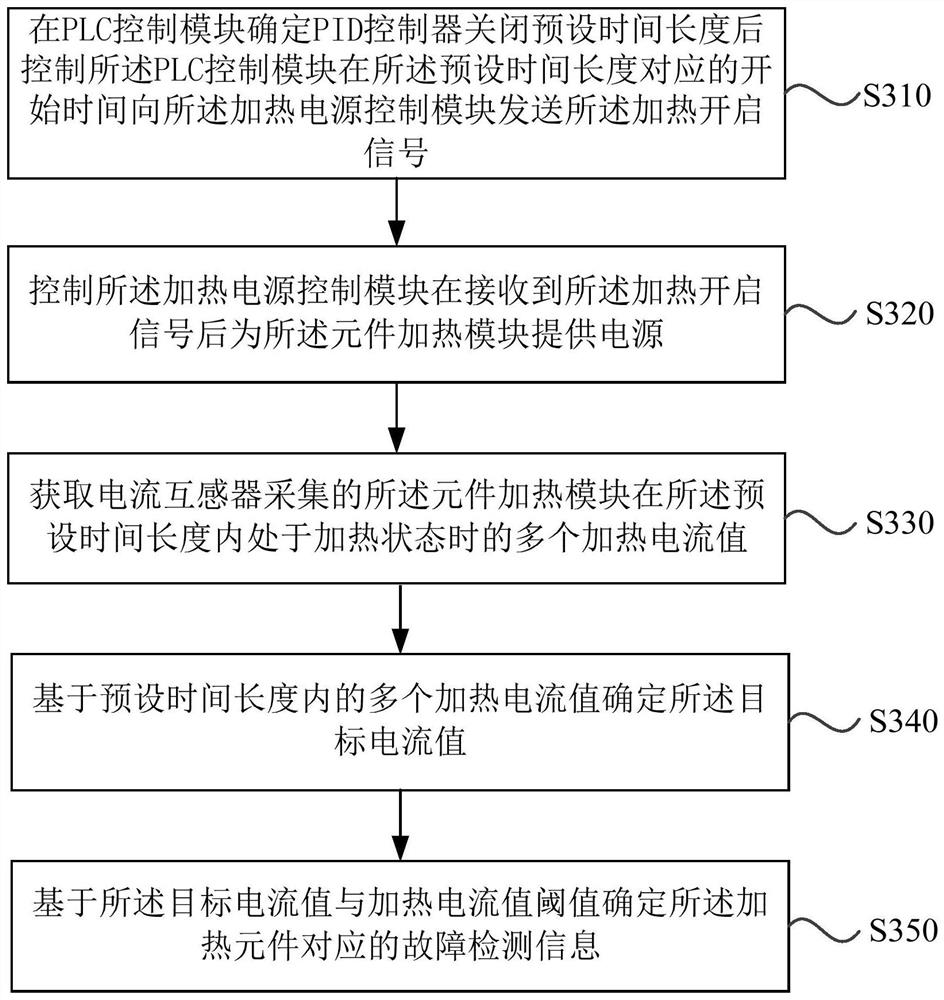

[0088] image 3 It is a schematic flowchart of a heating element detection method provided by Embodiment 3 of the present invention. The technical solutions of the embodiments of the present invention are further optimized on the basis of the above embodiments. The method of this embodiment specifically includes:

[0089] S310. After the PLC control module determines that the PID controller is turned off for a preset time length, control the PLC control module to send the heating start signal to the heating power supply control module at a start time corresponding to the preset time length.

[0090] S320. Control the heating power supply control module to provide power to the element heating module after receiving the heating start signal.

[0091] S330. Obtain a plurality of heating current values collected by the current transformer when the element heating module is in a heating state within the preset time length.

[0092] S340. Determine the target current value base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com