Ballastless track concrete structure damage detection method based on stress waves

A technology for concrete structures and ballastless tracks, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analysis materials. Detection and other problems, to achieve the effect of intuitive and clear detection results, simple test operation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

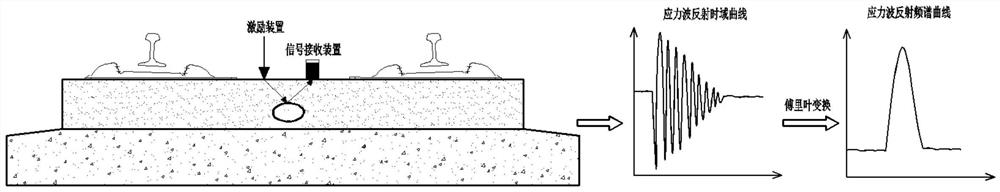

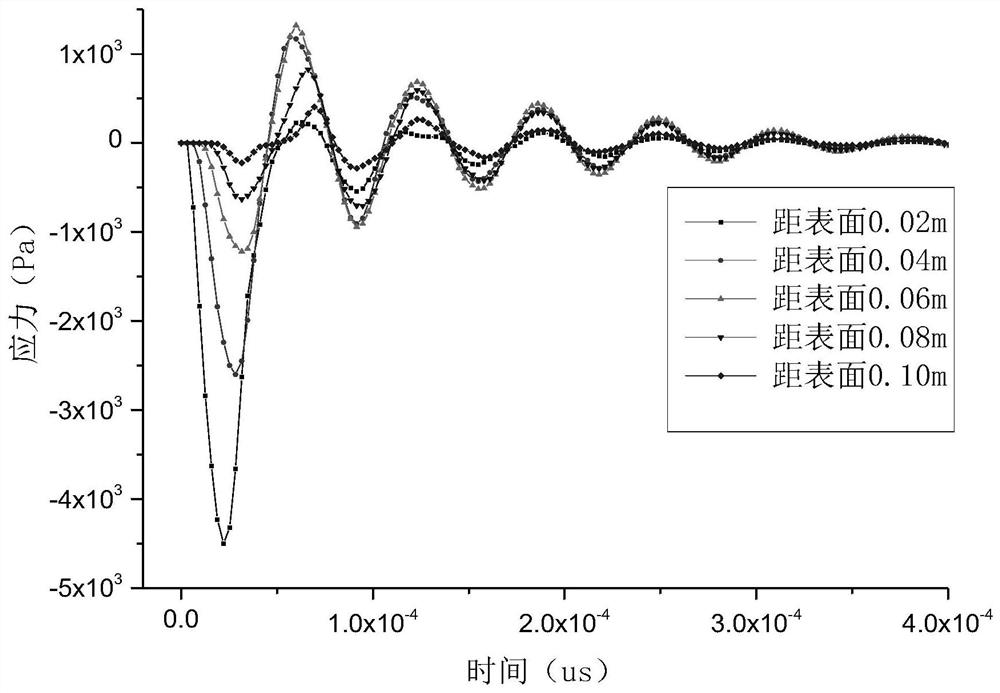

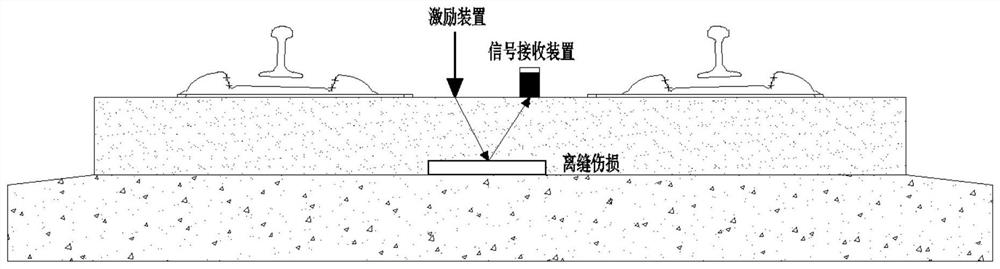

[0029] The invention relates to a damage detection method for a ballastless track concrete structure based on a stress wave. The method obtains the stress wave reflection spectrum curve according to the stress wave time domain signal obtained by an acceleration sensor arranged on the track plate, and obtains the stress wave reflection spectrum curve according to the peak value of the spectrum curve , through the relationship between the frequency and the stress wave, the depth of the stress wave reflection surface is back-calculated. If it is as thick as the track plate, that is, there is no damage in the track plate; Calculate the specific depth of damage.

[0030] This method specifically comprises the following steps:

[0031] Step 1: Arrange an acceleration sensor on the track plate, generate a stress wave by hammering, the acceleration sensor receives the time domai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com