Multifunctional self-adaptive maintenance platform and operation method thereof

A maintenance platform and self-adaptive technology, applied in the direction of lifting devices, etc., can solve the problems of difficult maintenance, single operation path, and inability to meet maintenance applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

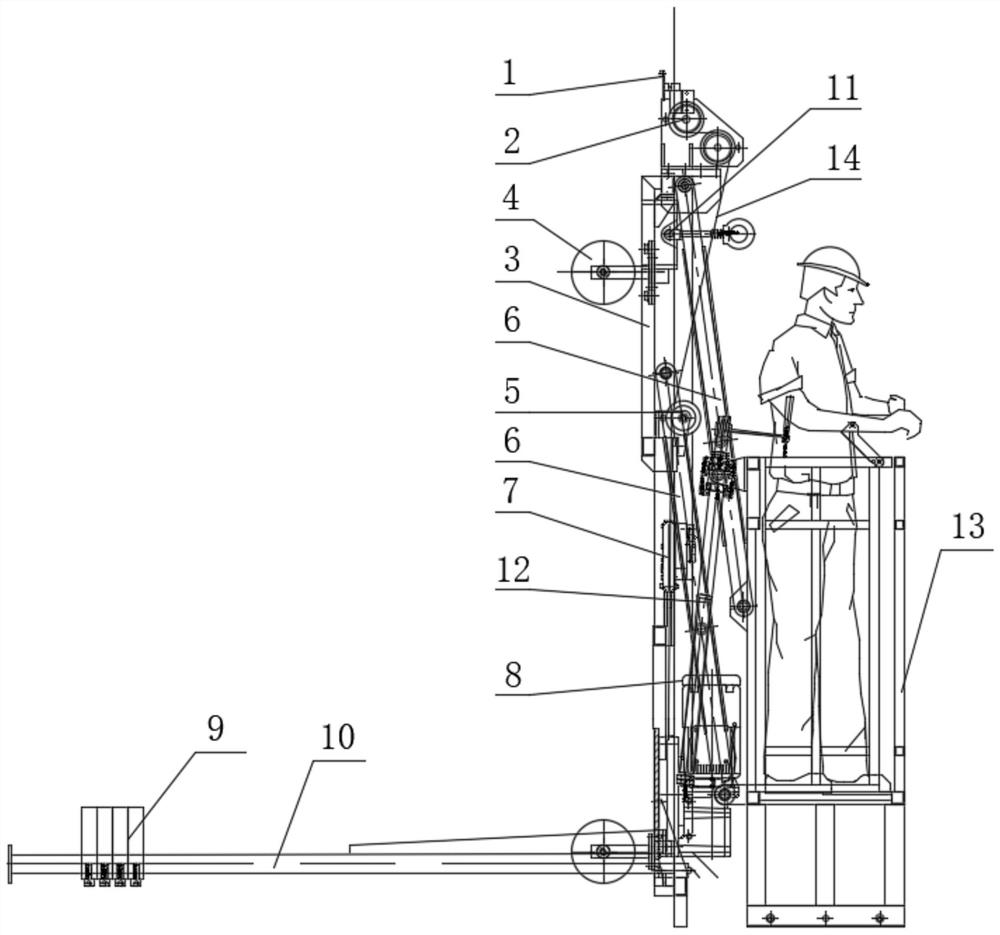

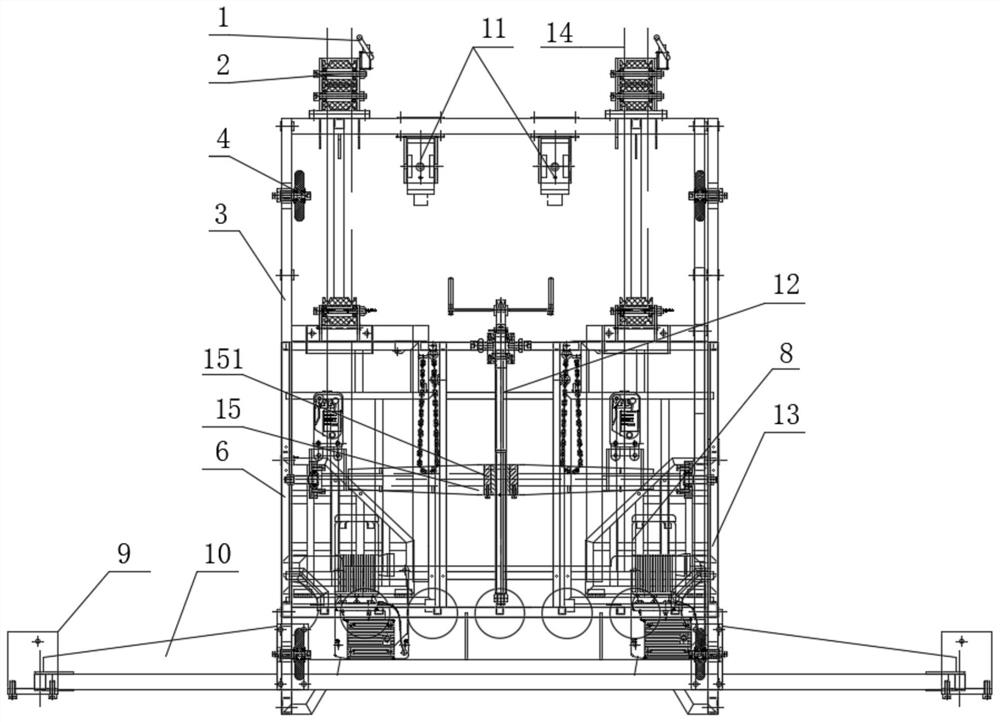

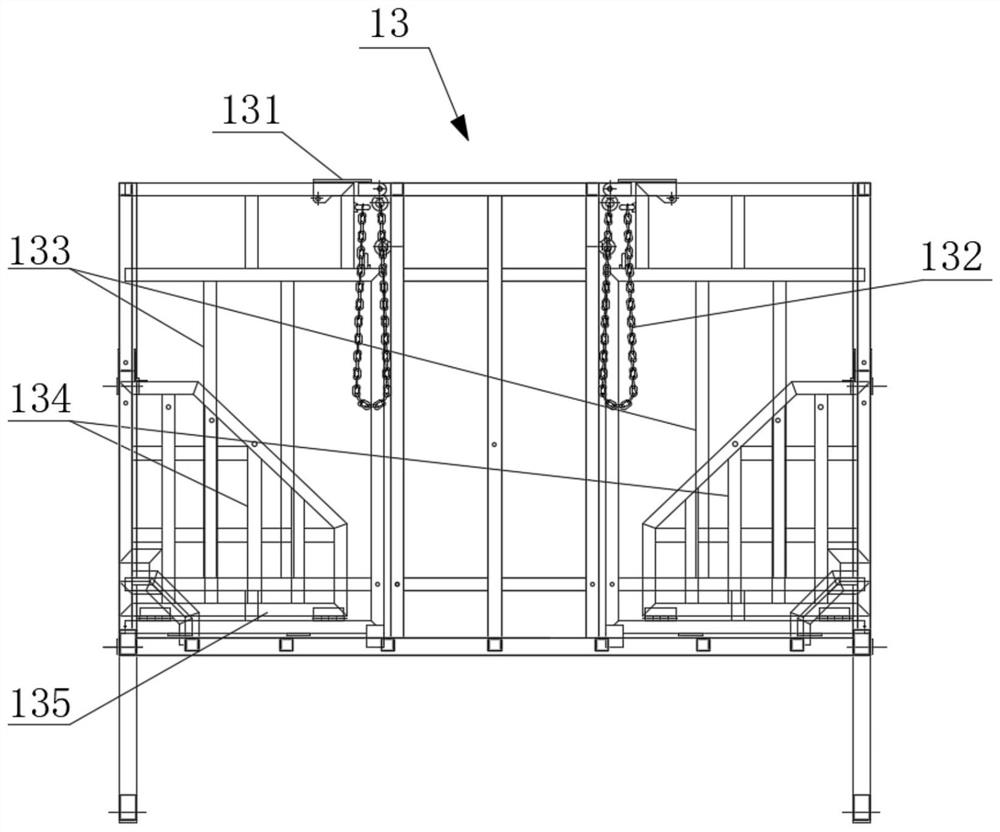

[0044] Such as figure 1 with figure 2 As shown, a kind of multi-functional self-adaptive maintenance platform of the present embodiment comprises lifting frame 3, and lifting frame 3 becomes square frame structure, and guide wheel assembly 2 is respectively installed on both sides of the upper part of lifting frame 3, and the middle part of lifting frame 3 The lower guide wheel assembly 5 is installed on both sides, and the hoist 8 is respectively installed on both sides of the bottom of the hoist 3, and a centrifugal safety lock 7 is installed on the hoist 3 above each hoist 8; the front side of the hoist 3 passes through the swing arm 6 and the screw mechanism 12 are connected with the working basket 13, and the counterweight 9 is installed on the rear side of the bottom of the lifting frame 3 through the counterweight bracket 10; Rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com