Crawler fire-fighting robot

A fire-fighting robot and crawler-type technology, applied in fire rescue, TV, color TV parts and other directions, can solve problems such as damage, increased fire-fighting time, and inability to work normally, and achieve good protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

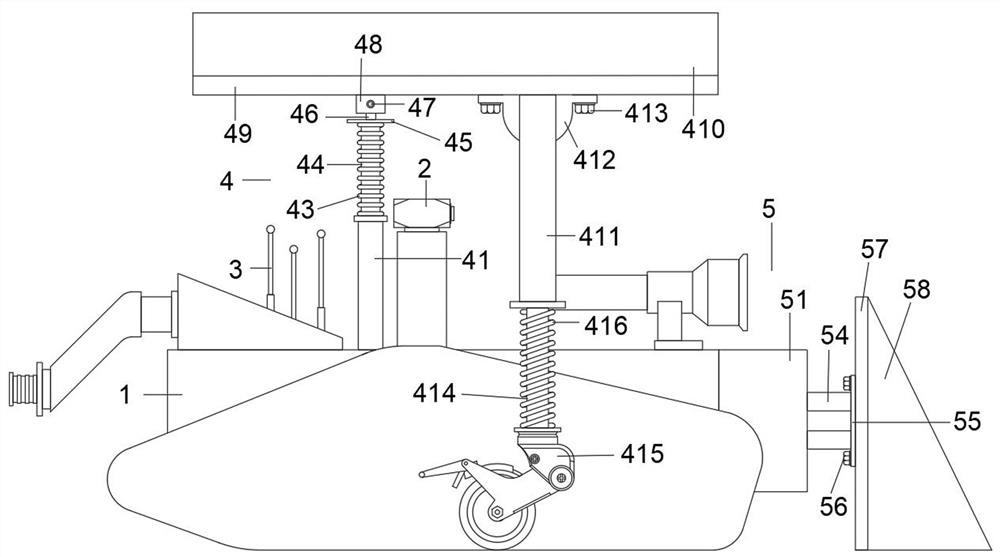

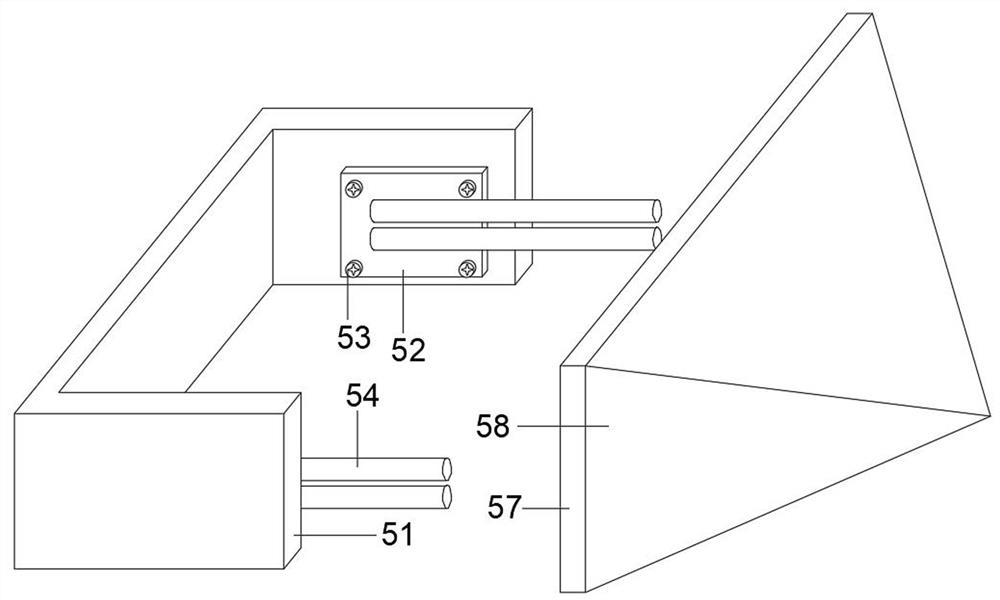

[0022] Such as Figure 1-3 As shown, the specific embodiment adopts the following technical solutions: a crawler-type fire-fighting robot, including a fire-fighting robot 1, the top of the fire-fighting robot 1 is provided with a camera 2, and the top of the fire-fighting robot 1 is located on one side of the camera 2. Sensing antenna 3, the top of the fire extinguishing robot 1 is located between the camera 2 and the sensing antenna 3, and a protective mechanism 4 is connected, and a cleaning mechanism 5 is provided on one side wall of the fire extinguishing robot 1.

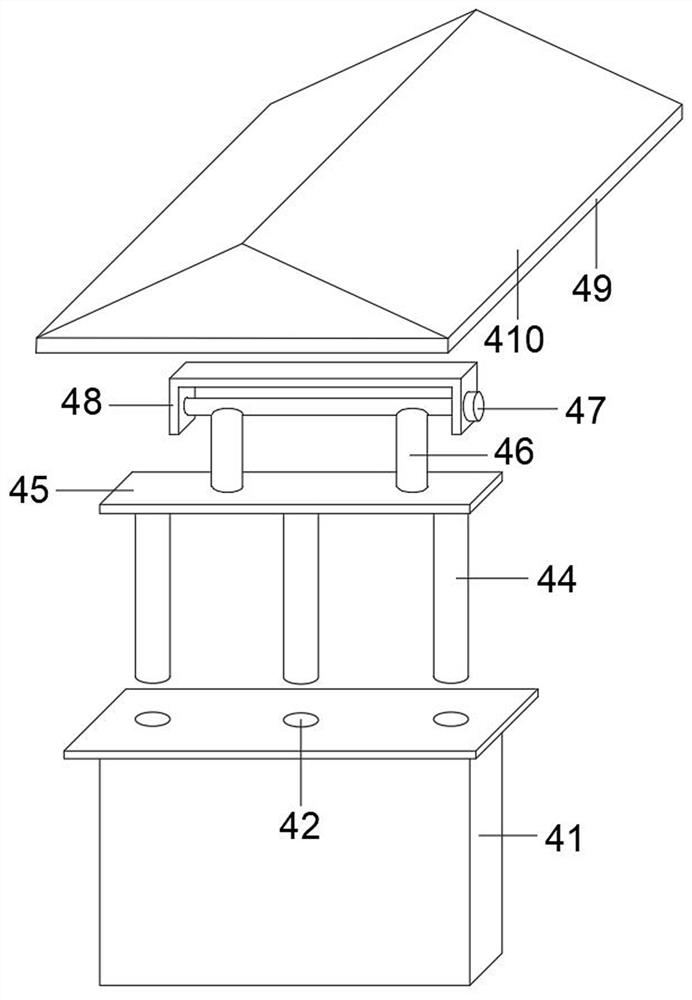

[0023] Wherein, the protection mechanism 4 includes a support column 41, a slot 42, a No. 1 spring 43, a damping rod 44, a top plate 45, a connecting column 46, a movable shaft 47, a U-shaped seat 48, a movable plate 49, and a No. 1 triangular block. 410, U-shaped pipe 411, fixed seat 412, No. 1 bolt 413, inner rod 414, universal wheel 415 and No. 2 spring 416, and a plurality of slots 42 are dug on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com