High-voltage switch cabinet

A high-voltage switchgear and pressure relief technology, applied in the field of switchgear, can solve the problems of difficult to fully guarantee safety performance and many triggering conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

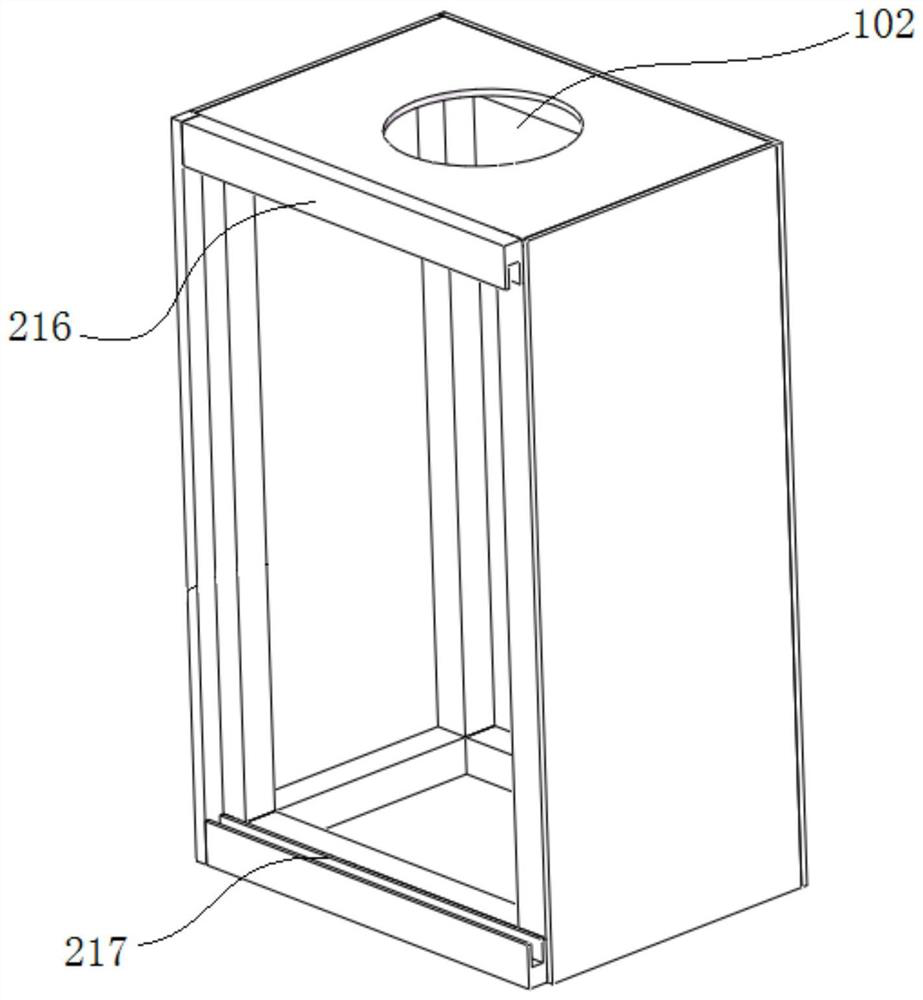

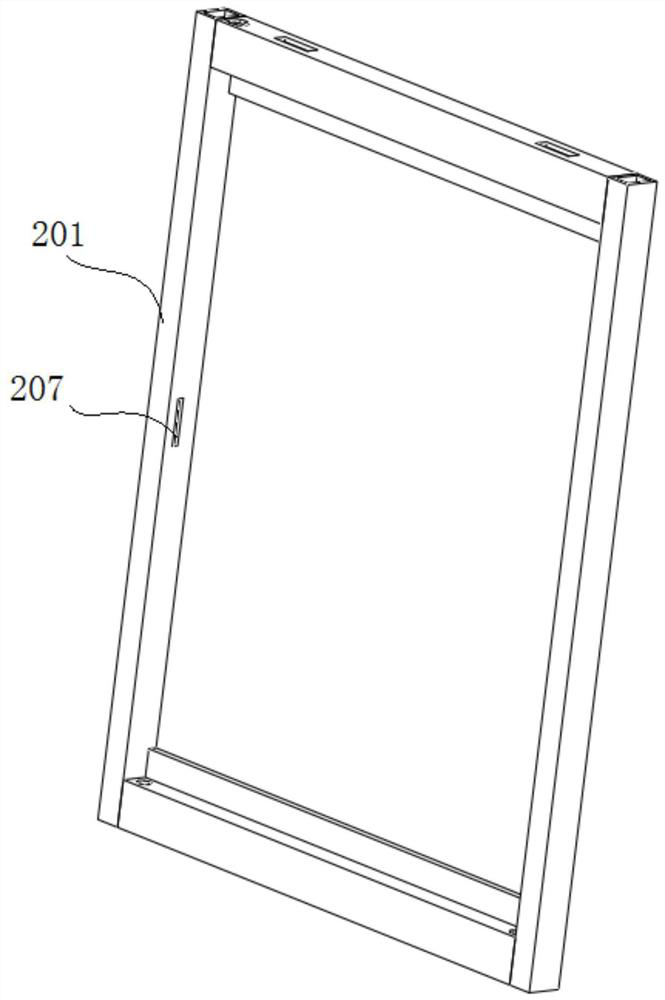

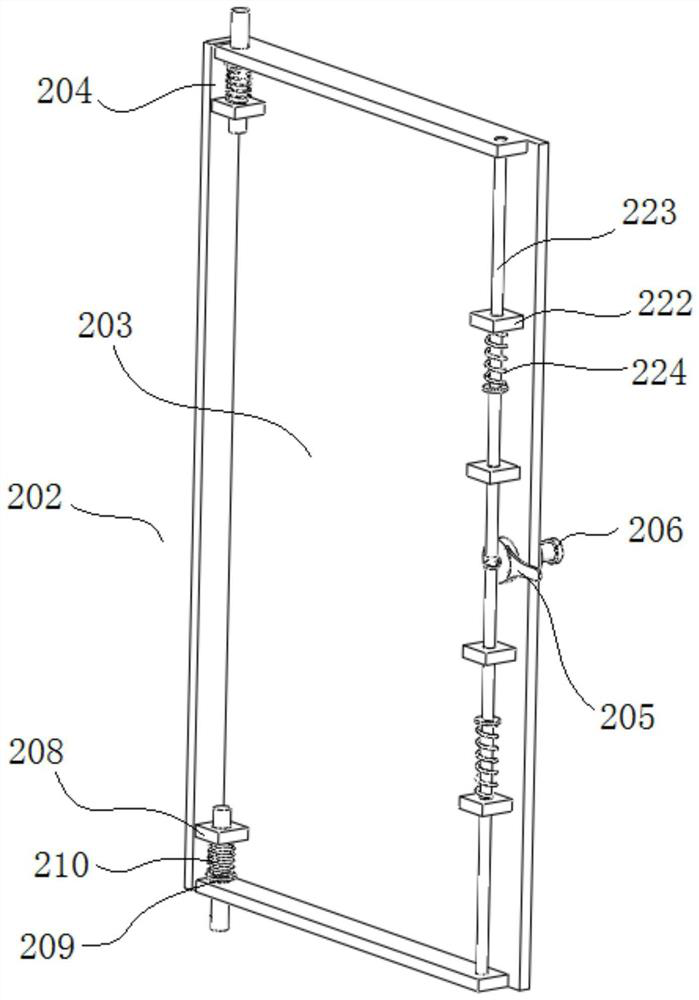

[0032] A high voltage switchgear, such as Figure 1-Figure 6 As shown, the cabinet body is provided with a cabinet door. The cabinet door includes a door frame 201. The door frame 201 is a cuboid frame structure including an upper end bar, a lower end bar, a left end bar and a right end bar. The upper end bar of the frame of the door frame 201 and The lower end rods are respectively provided with limiting plates extending towards the frame to limit the door body 202. When the door body 202 is fastened in the door frame 201, the upper and lower ends of the rear end surface of the door body 202 are respectively against the upper and lower limit positions. on the board to prevent the door body 202 from being pushed into the inside of the switch cabinet.

[0033] Door body 202 is hinged in door frame 201, and door body 202 comprises door panel 203, also comprises the upper end plate and the lower end plate that are respectively arranged on the upper and lower ends of door panel 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com