Oyster shell pulverizing and screening device for production of soil remediation agent

A technology for soil remediation agent and oyster shell powder, which is applied in the directions of sieves, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems such as the inability to perform pulverization work and screening work at the same time and the slow work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example

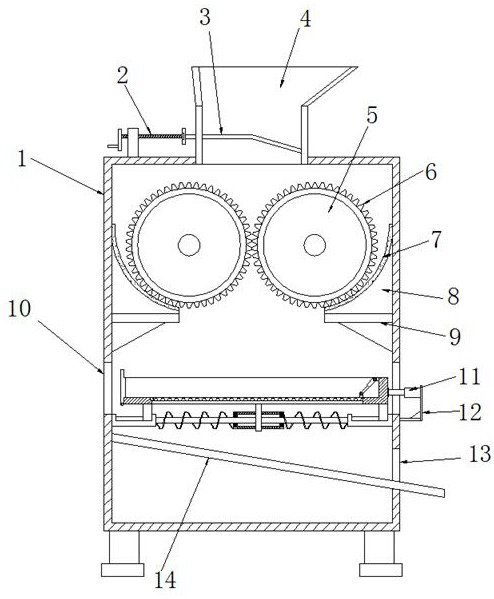

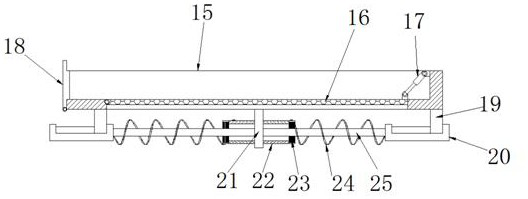

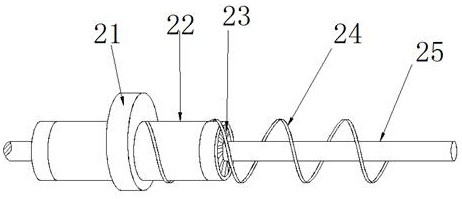

[0026] refer to Figure 1-4 , an oyster shell pulverization and screening device for soil remediation agent production, comprising a box body 1, two relatively rotating crushing rollers 5 are installed on the top of the box body 1, and convex ribs distributed equidistantly are fixed on the outer wall of the crushing roller 5 6. A symmetrical support frame 9 is fixed on the inner wall on both sides of the box body 1. A grinding mechanism that fits the outer surface of the crushing roller 5 is fixed on the support frame 9. The outer wall on the opposite side of the box body 1 has a movable opening 10. 10 is fixed with a slide rail 20 at the bottom position inside the slide rail 20, and a slide block 19 is slidably clamped on the slide rail 20, and the same screening mechanism is fixed on the top of the slide block 19, and a guide rod 25 is fixed between the two slide rails 20, and guide The rod 25 is movably socketed with a guiding mechanism fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com