Tent with center-driven long louver canopy opening and closing structure

A technology of opening and closing structure and center drive, which is applied in the direction of building structure, construction, sunshade, etc., and can solve the problems of high labor cost, cumbersome, pin shaft screw falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

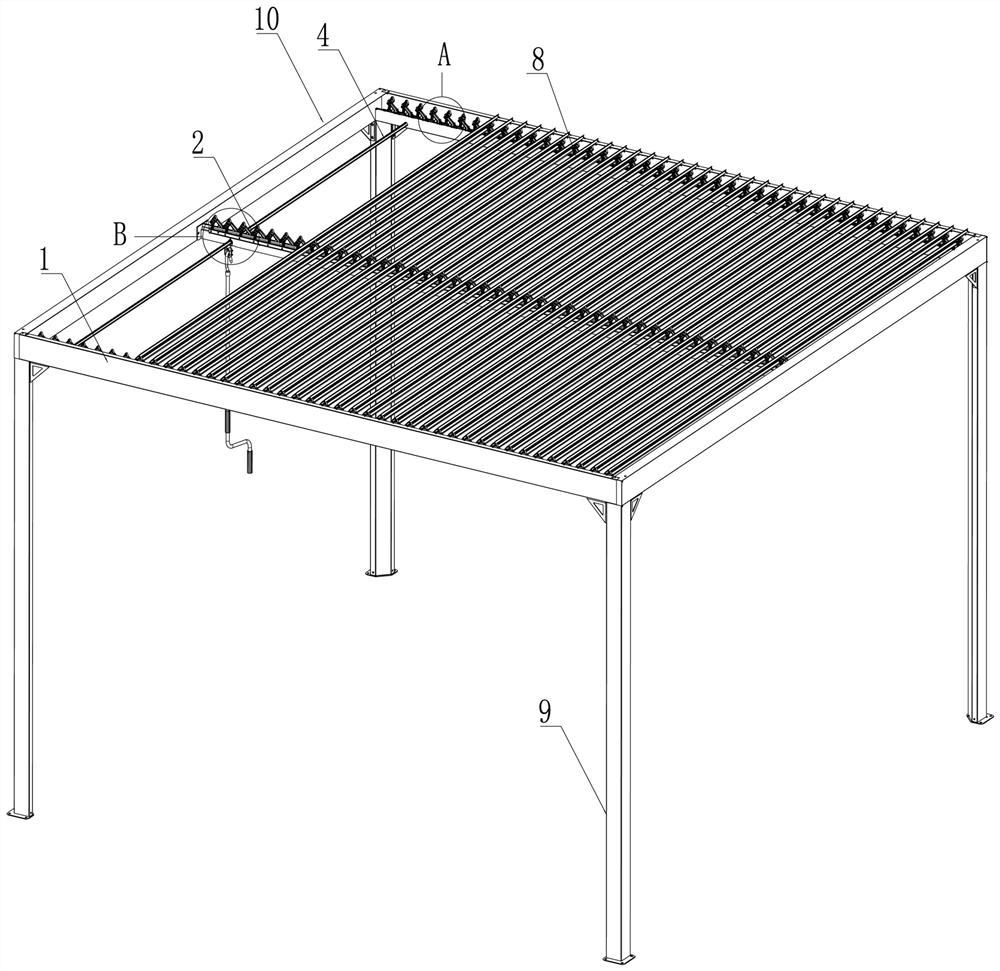

[0044] Such as Figure 1-21 As shown, a tent with a center-driven long-louver roof opening and closing structure includes:

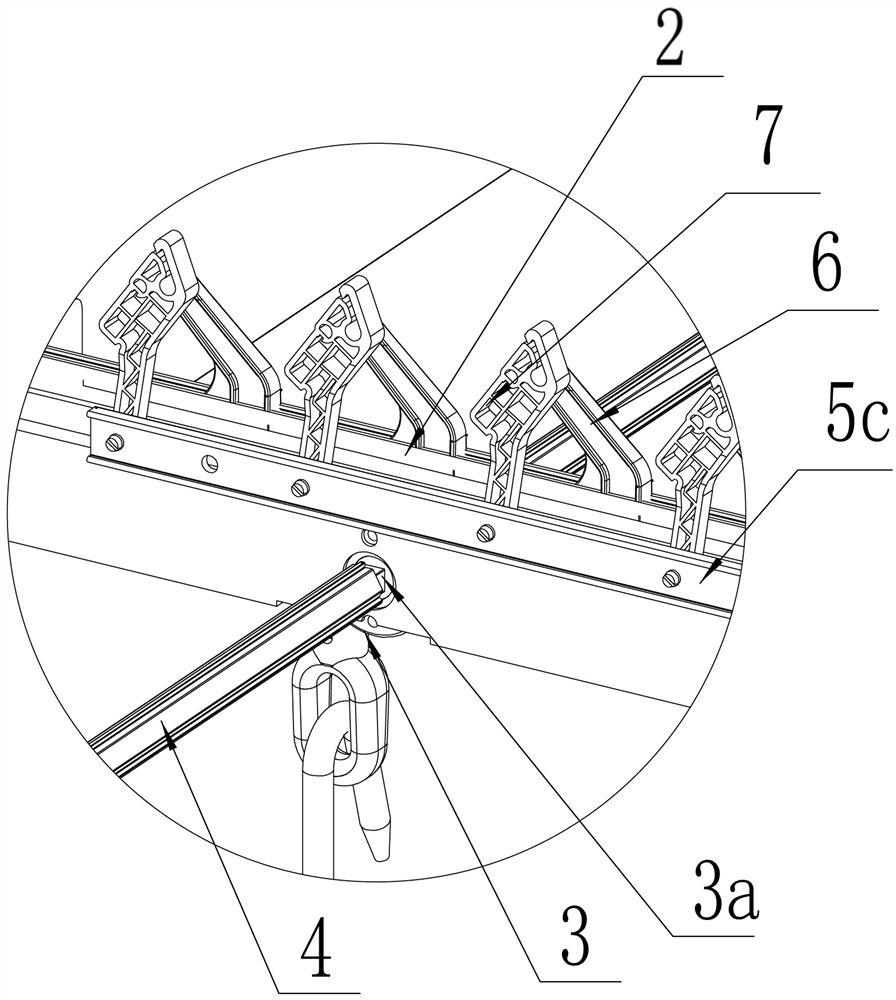

[0045] A tent frame, the tent frame includes a first ring beam 1 located at the left and right ends of it and a middle beam 2 located between the two first ring beams 1;

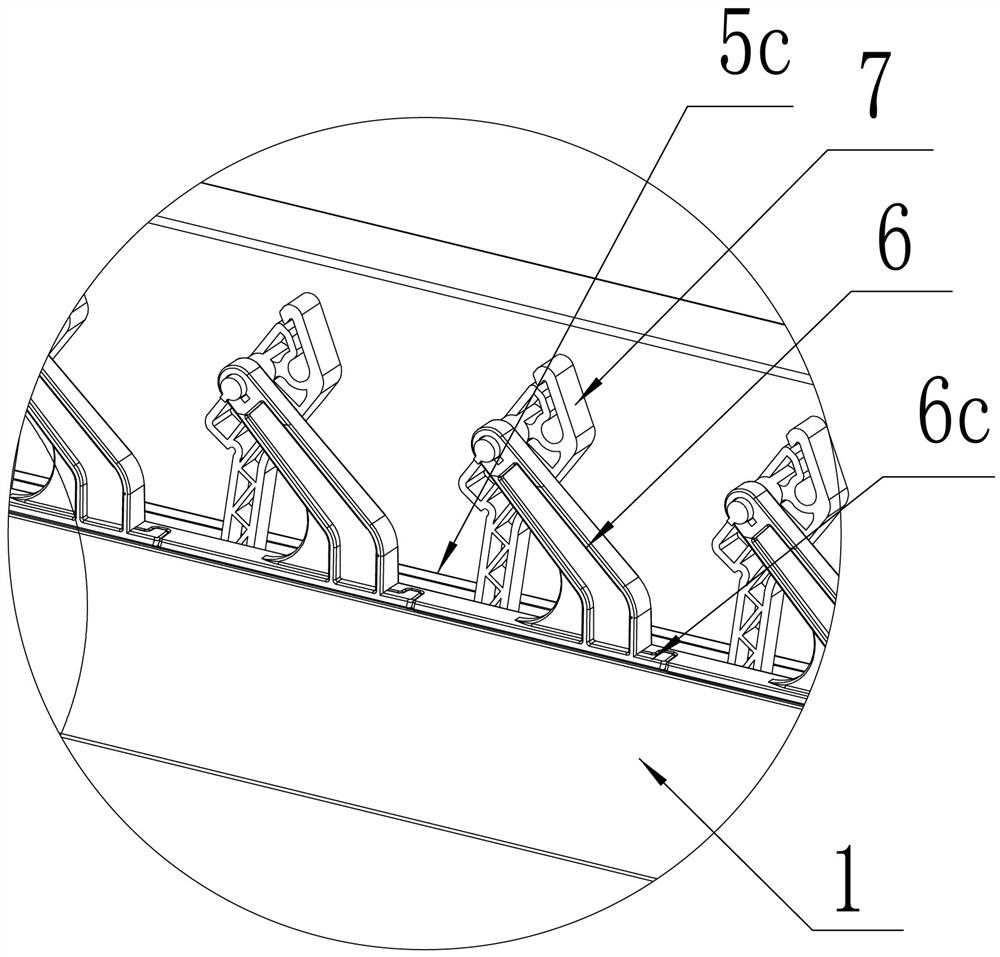

[0046] The louver group, the louver group includes a group of louver plates 8 arranged in a row, the two ends of the louver plate 8 are installed and matched with the two first ring beams 1 through a set of first installation components, and the middle part of the louver plate passes through a set of The second installation assembly provided is installed and matched with the center beam 2, the installation assembly includes a louver plate fixing seat 6 and a louver plate rotating member 7, and one end of the louver plate fixing seat 6 is clamped and fitted with the corresponding fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com