Motor rotor, motor and vehicle

A technology of motor rotor and rotor core, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem that the motor rotor cannot be effectively dissipated, and achieve the effects of improving heat dissipation effect, assembly efficiency, and heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

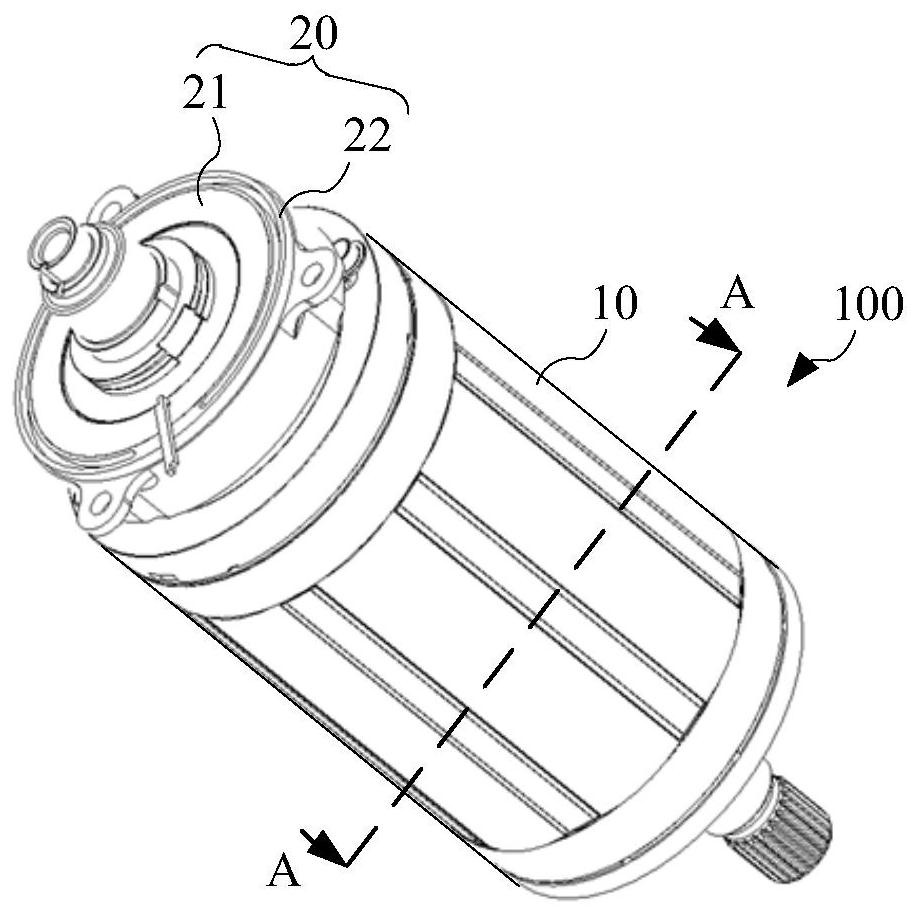

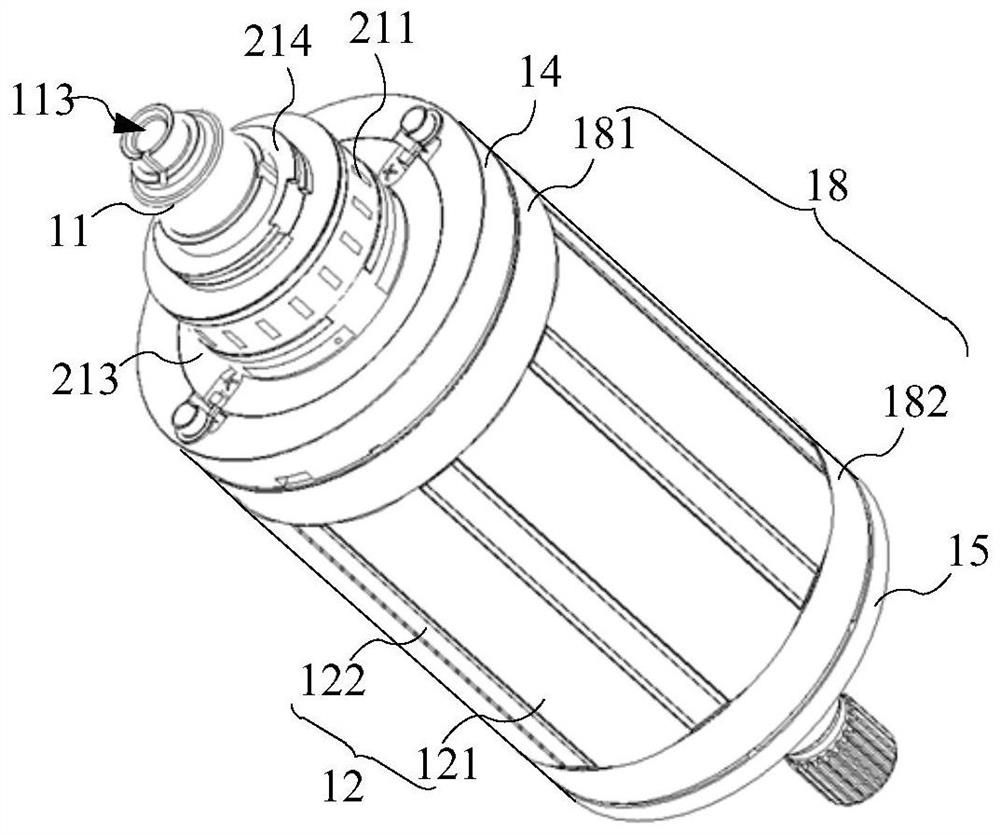

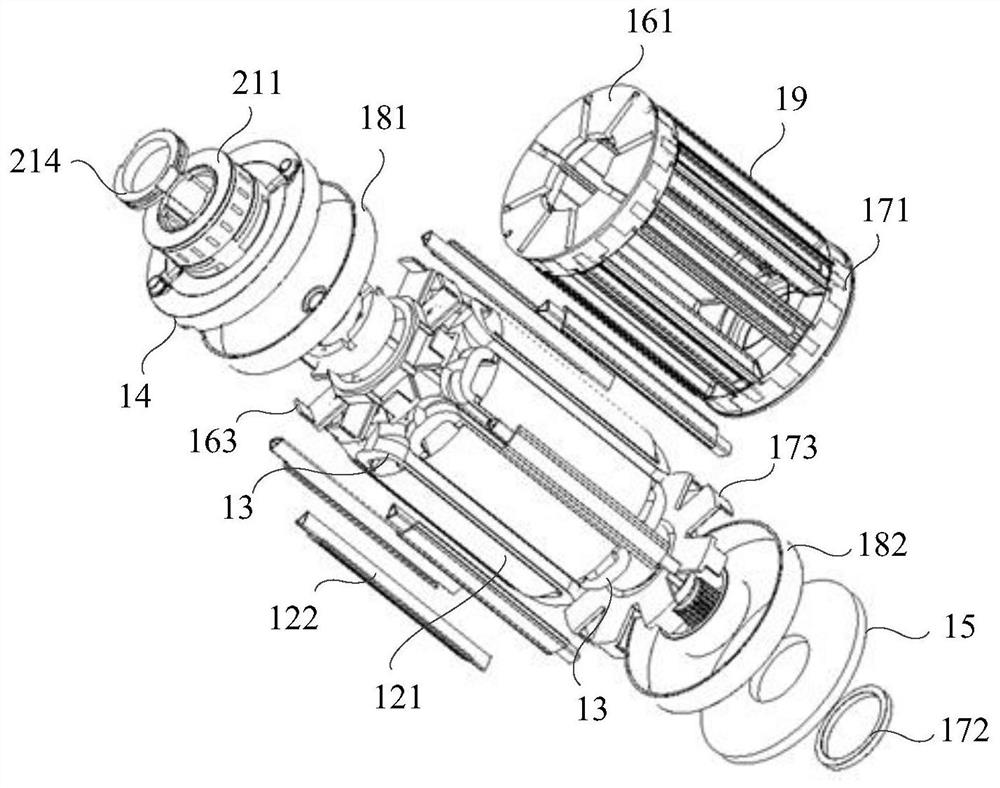

Image

Examples

Embodiment Construction

[0095] The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

[0096] In the traditional technology, the motor includes a stator and a rotor, the stator is movably sleeved on the outer periphery of the rotor, and the rotor is connected to loads such as wheels. When working, the stator generates a rotating magnetic field in the air gap between the stator and the rotor. When the excitation winding of the rotor is fed with DC current, it will generate a static magnetic field with constant polarity. Under the action of the armature reaction, the rotor generates a magnetic field relative to the stator. Torque, thereby driving the load to move.

[0097] From the above working process of the motor, it can be known that the rotor of the motor needs to rotate at a high speed to drive the load to move, so compared with the stator, the heat generated dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com