Highly automated split screw conveyor

A screw conveyor and split technology, which is applied in the field of split screw conveyors, can solve problems such as insufficient fineness, difficulty in transportation and installation, and poor stability, and achieve the effects of reducing contact, smooth damage, and strengthening the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

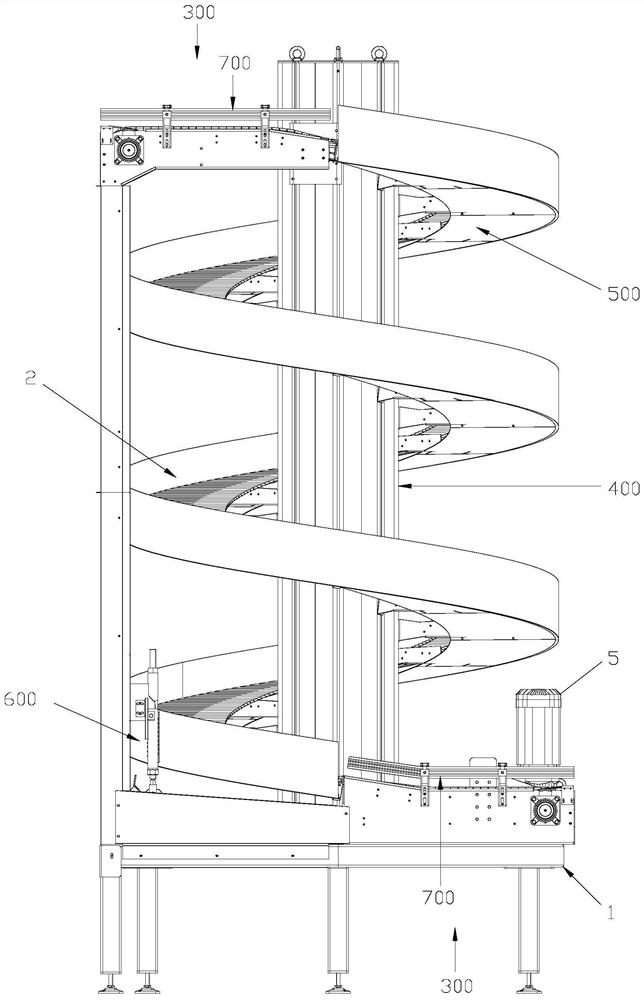

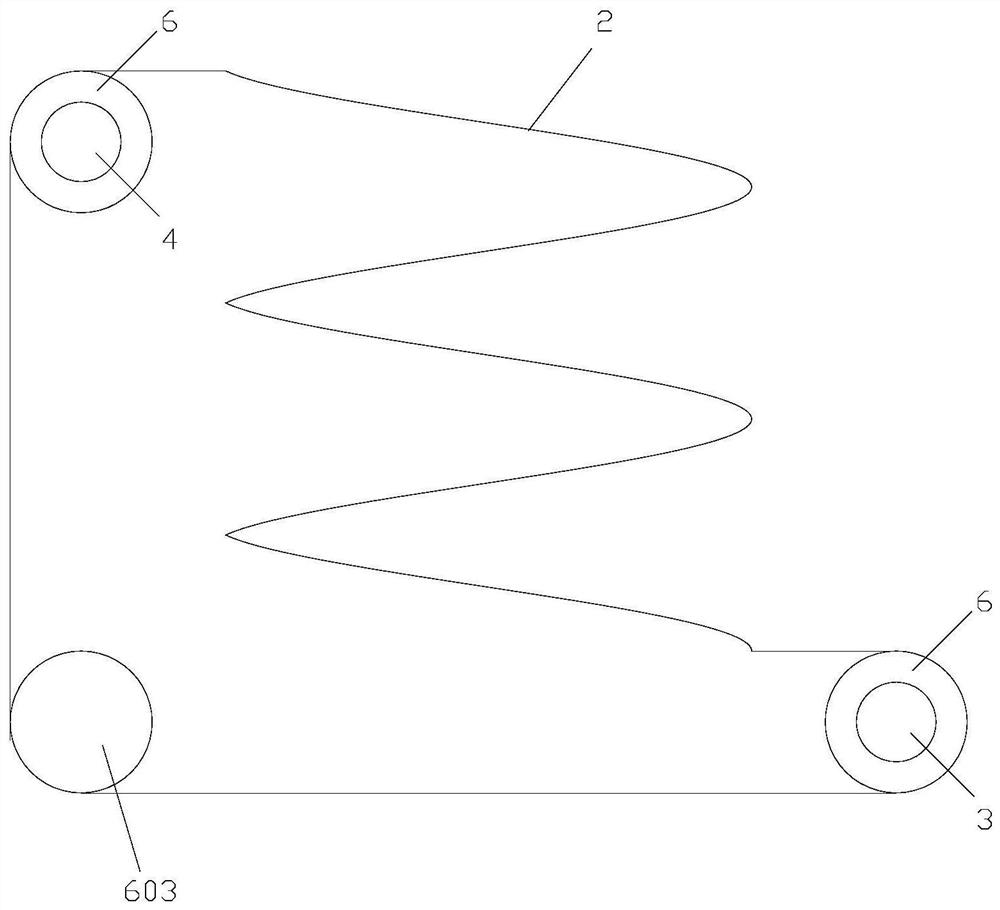

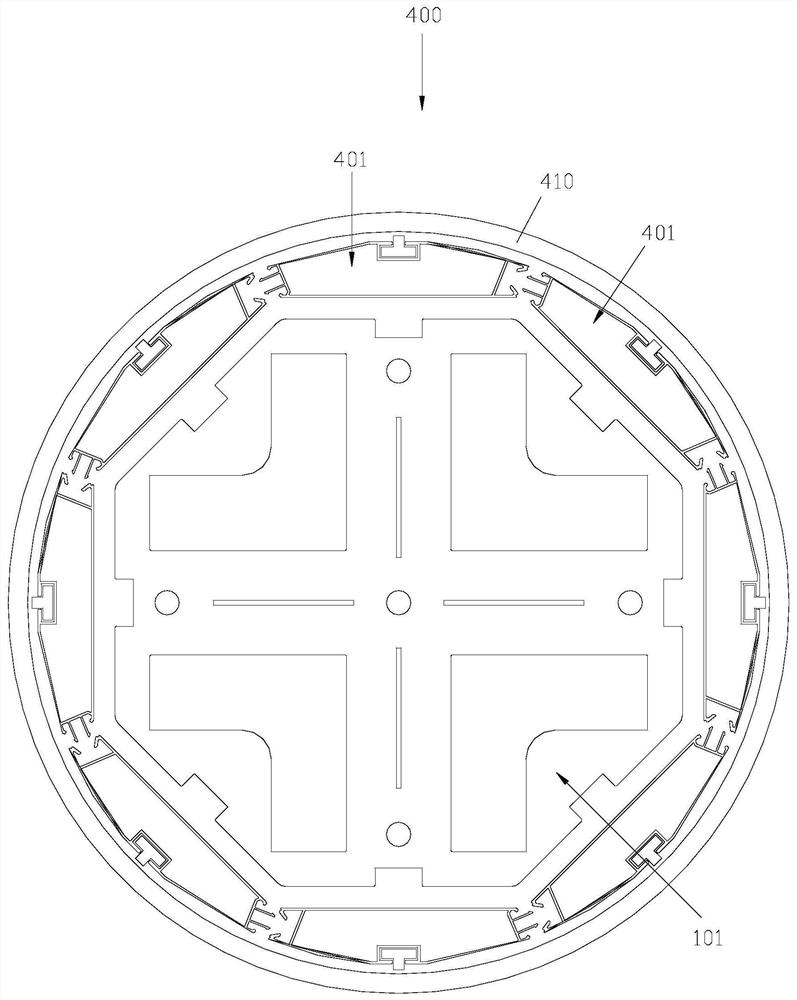

[0044] Embodiment of the present invention: a highly automated split type screw conveyor, constituted as Figure 1 to Figure 17 , see Figure 1 and figure 2 , including a support base 1, a central axis support column 400, a supporting member 500, a conveyor belt 2, a driving roller 3, a driven roller 4, a driving motor 5 and a tensioning assembly 600, and the central axis support column 400 is fixedly arranged on the support base 1, the central axis support column 400 is spirally provided with several supporting parts 500 from bottom to top, and the bottommost supporting part 500 is provided with a driving roller 3, and the driving roller 3 is driven by a driving motor 5 , the uppermost supporting member 500 is provided with a driven roller 4, the conveyor belt 2 is connected end to end and encircles the driving roller 3, the supporting member 500 and the driven roller 4 in sequence, and the tensioning assembly 600 Tension the conveyor belt 2.

[0045] The central axis suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com