A visual test system for simulating crack propagation in rock mass under the condition of multi-hole blasting

A technology of crack propagation and test system, applied in the field of geotechnical engineering test, can solve problems such as the inability to realize visual detection, and achieve the effect of reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principle of the present invention, and are not intended to limit the protection scope of the present invention.

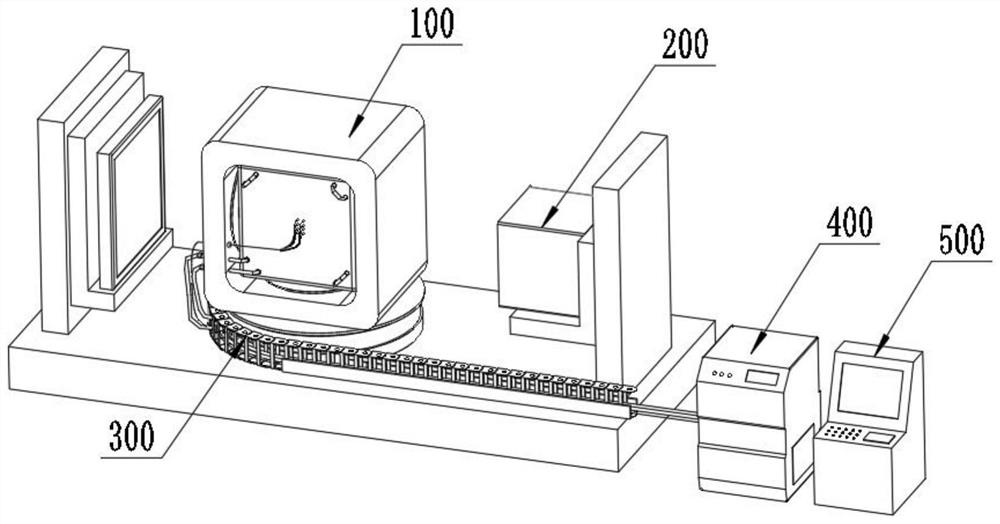

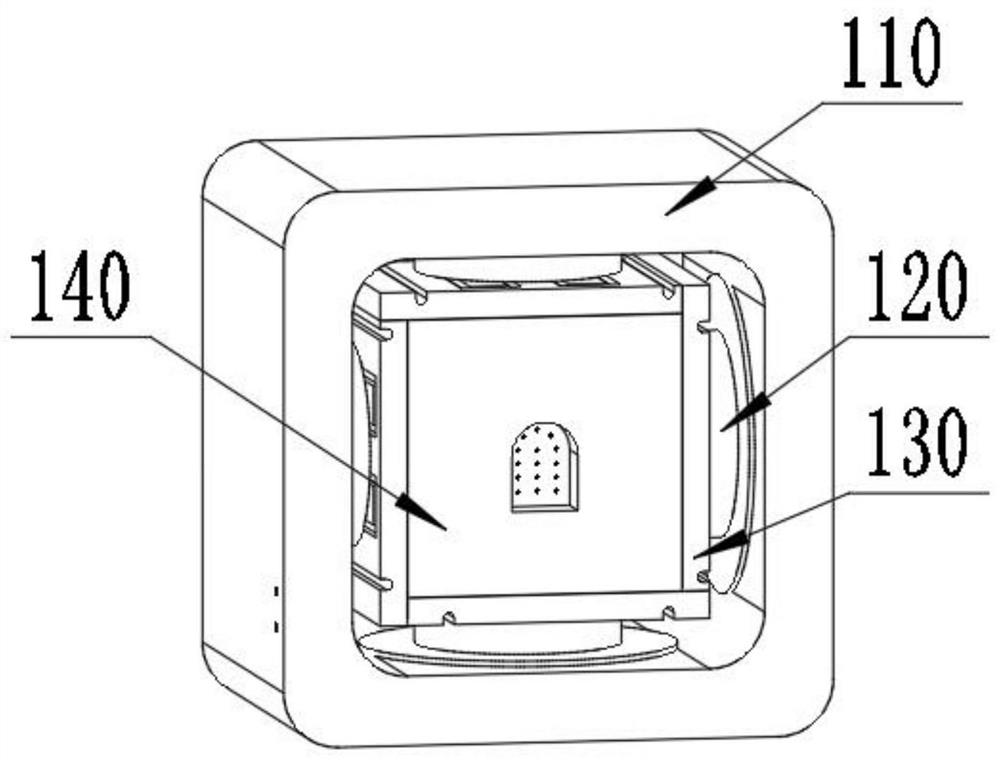

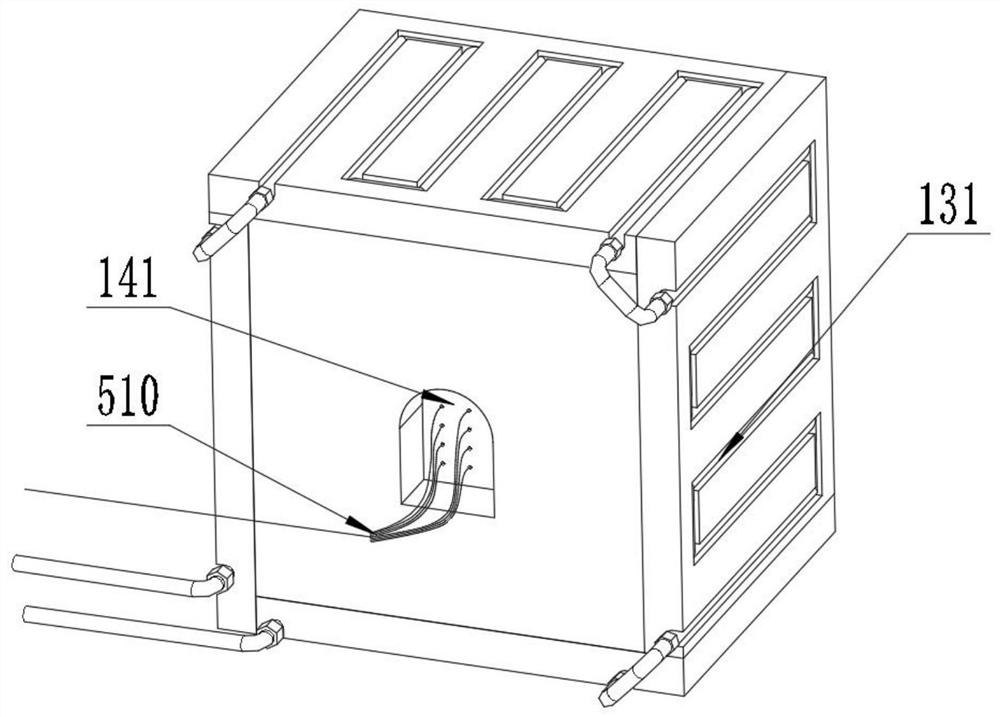

[0045] The invention provides a visual test system for simulating the expansion of cracks in rock mass under the condition of multi-hole blasting, including a high-energy accelerator CT detection system, a test cabin system, a temperature control system, a blasting control system and a rotating bearing system, wherein the high-energy accelerator CT detection system The system is used to scan and detect the deformation of the rock mass in the test piece caused by blasting, and obtain the three-dimensional expansion process of cracks in the test piece under different blasting parameters, so as to obtain reliable test data and provide valuable data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com