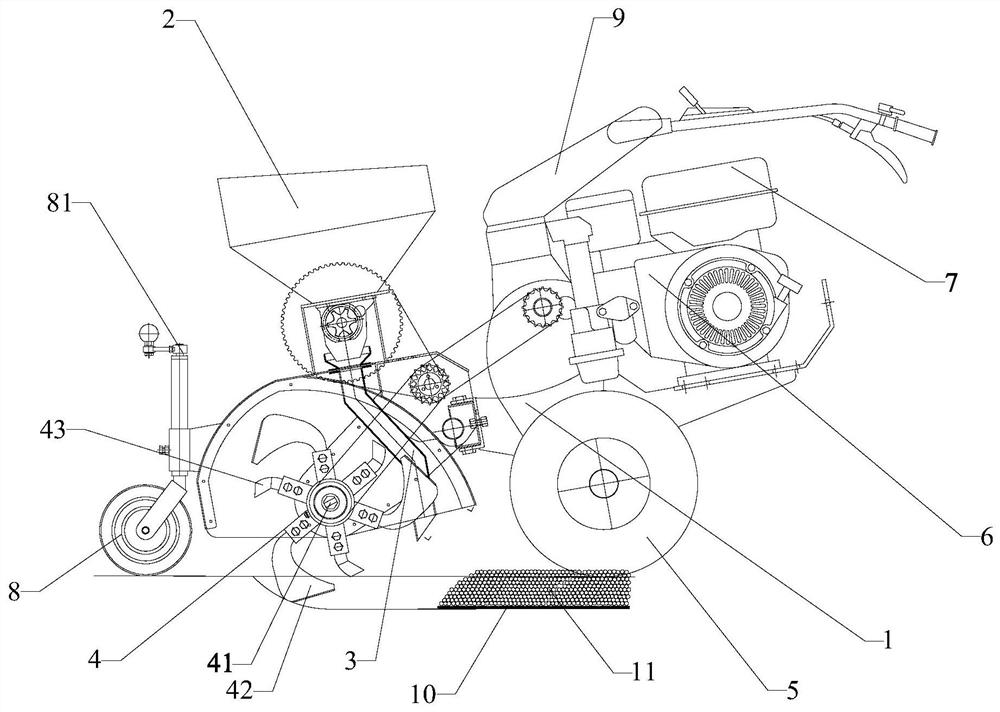

Fitching, fertilizing and earthing integrated working machine

A combined operation machine and soil-covering technology, which is applied to fertilization devices, excavation/covering ditches, agriculture, etc., can solve the problems of insufficient fertilizer burial depth and root burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

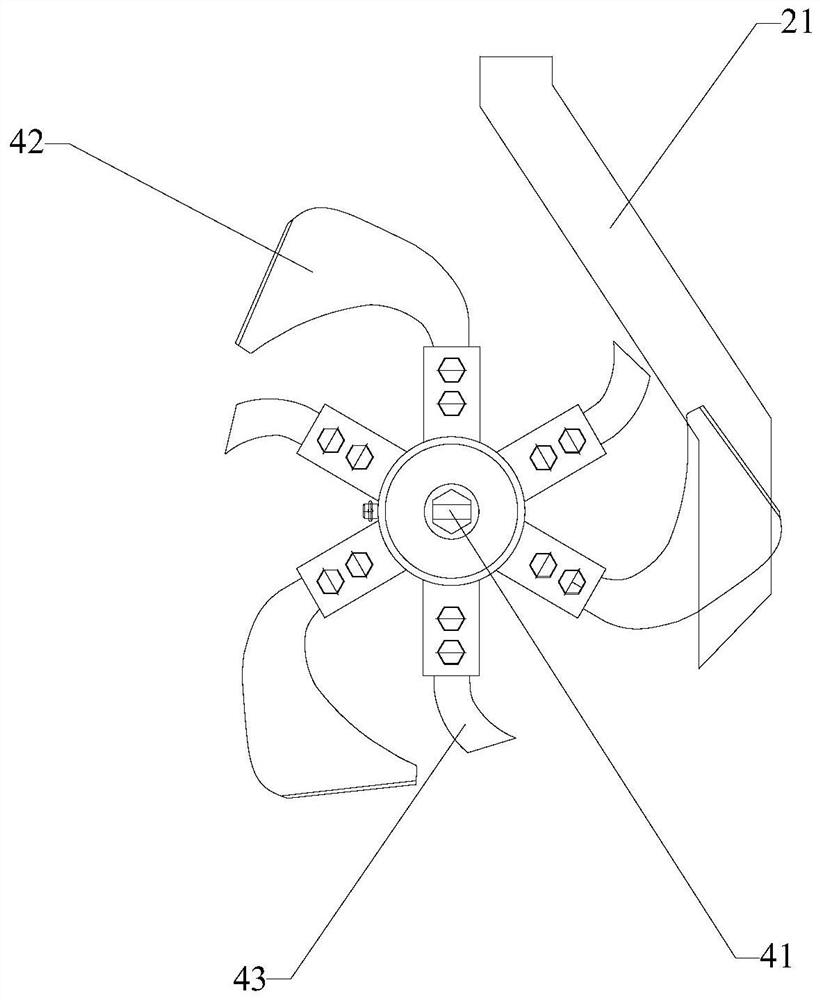

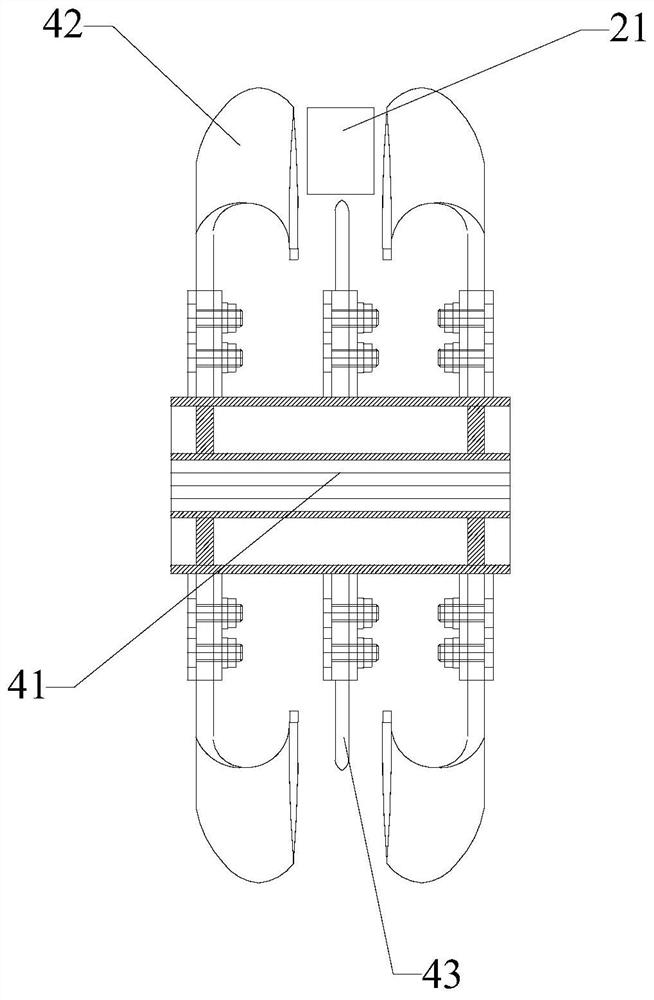

[0041]A combined operation machine for ditching, fertilizing and soil covering, comprising a fertilization box 2, a soil guide casing 3, and a ditching and soil guiding mechanism 4 arranged sequentially from top to bottom on a frame 1; the ditching and soil guiding mechanism 4 includes Rotating shaft 41 and the coulter 42 that is connected on the rotating shaft 41 to guide soil, the turning of the rotating shaft 41 is opposite to that of the frame 1 driving wheel 5; the lower end of the fertilizing box 2 is connected with a conduit 21, and The outlet end is located at the rear and lower side of the rotating shaft 41 relative to the working direction. The ditching soil guiding coulters 42 are symmetrically distributed on both sides of the conduit 21, and the distance between the outer edge of the ditching soil guiding coulters 42 and the rotating shaft 41 is greater than that of the conduit 21 The distance between the lower end and the rotating shaft 41; the shape of the soil gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com