Dual-drive mopping, polishing and bottle washing device with self-balancing or self-compensating function

A dual-drive, self-balancing technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve problems such as displacement deflection, work and life hazards of drive devices, and achieve the effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

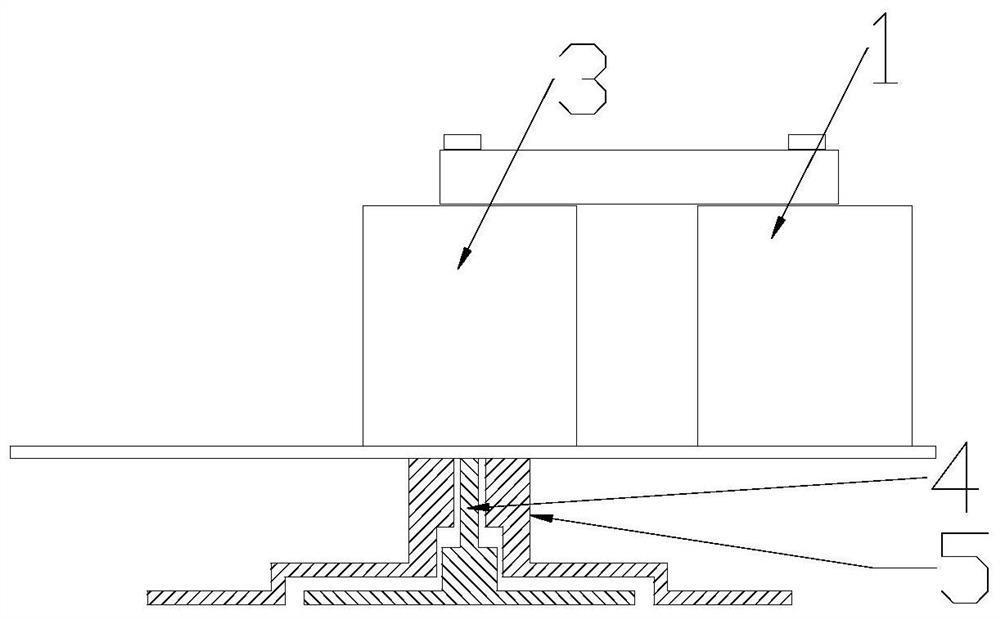

[0033] Such as figure 1 As shown, the present embodiment provides a double drive device with self-balancing function, the double drive device includes: a motor 1 and a double drive reducer 3, both of which are horizontally arranged; the motor 1 passes through a transmission mechanism such as a belt The transmission modes such as transmission, gear transmission or chain transmission are connected with the double-drive reducer 3; the output device adopted in this embodiment is the double-drive reducer 3, and the inner shaft power output end of the double-drive reducer 3 is used as the first output end 4. The output end of the outer shaft of the dual-drive reducer 3 is used as the second output end 5, the outer shaft is a hollow shaft, and the inner shaft can rotate in the opposite direction coaxially in the outer shaft.

[0034] When in use, start the motor 1 and connect the double-drive reducer 3 through the transmission mechanism, and at the same time, the first output end 4 a...

Embodiment 2

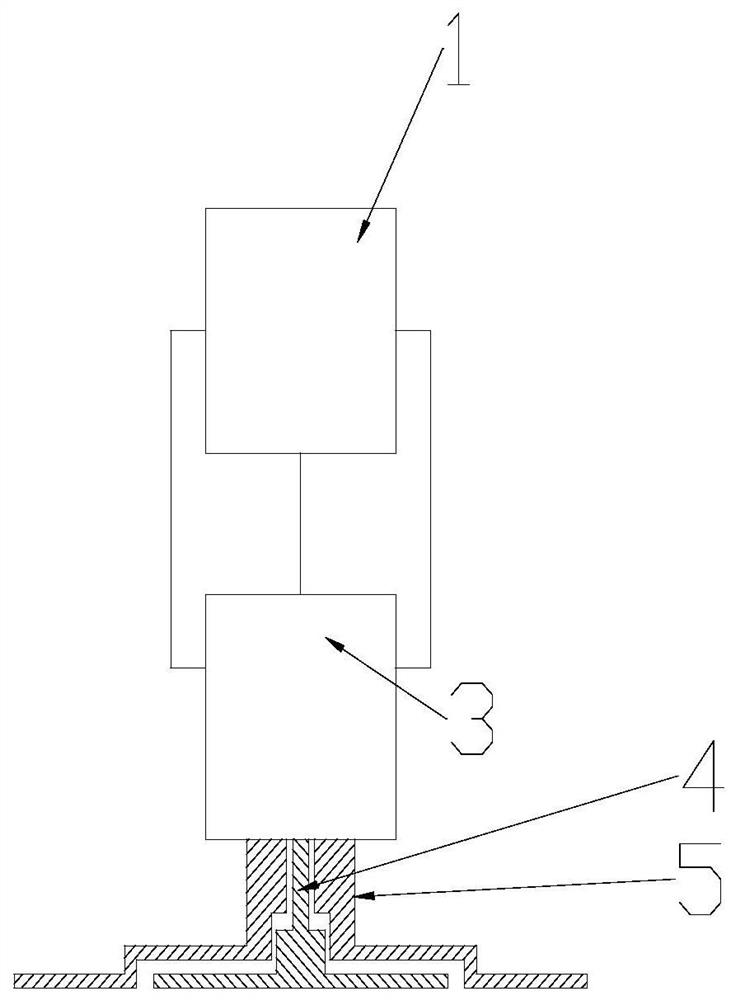

[0037] Such as figure 2 As shown, this embodiment provides a dual-drive device with self-balancing function. Since the motor 1 of the dual-drive device and the double-drive reducer 3 in Embodiment 1 are arranged horizontally and laterally, there is a certain deflection problem during actual use. , the use effect is not ideal, so on the basis of embodiment 1, embodiment 2 is improved as follows: the motor 1 is arranged above the reducer 2, and the casing of the motor 1 is connected with the casing of the double-drive reducer 3 as a whole.

[0038] The dual-drive device described in the above-mentioned embodiments 1-2 can directly adopt the dual-drive deceleration mechanism (also known as the dual-power deceleration mechanism in the early stage) commonly used in the washing machine industry, for example, disclosed in patents such as CN03101149.7 and CN200710110784.3 The dual-drive (or claiming dual power) deceleration output mechanism can be used for above-mentioned embodiment ...

Embodiment 3

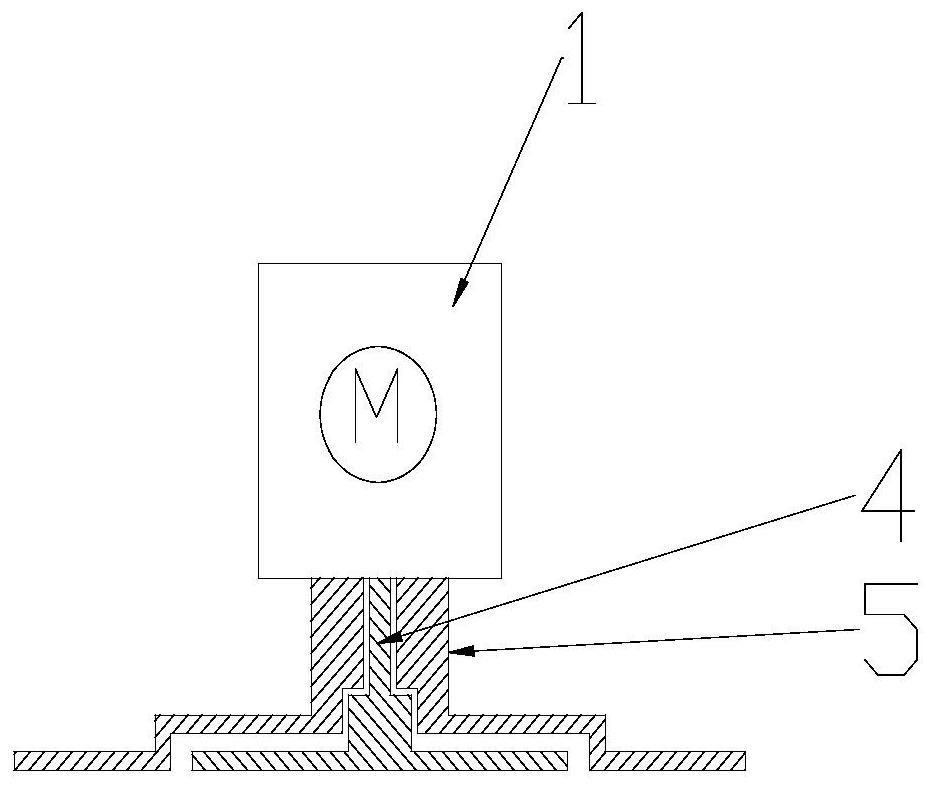

[0040] Such as image 3 As shown, the present embodiment provides a dual drive device with self-compensation function, the dual drive device includes: a motor 1; the output device used in this embodiment is the motor 1, the rotor output end of the motor 1 As the first output 4 , the housing of the electric motor 1 serves as the second output 5 .

[0041] When in use, the motor 1 is started, and then the first output end 4 rotates, and the second output end 5 and the first output end 4 generate relative motion in opposite directions.

[0042] When the contact surface of the first output end 4 is resisted during the rotation process, the rotating speed decreases, and the corresponding rotating speed of the second output end 5 increases, so that the resistance received by the second output end 5 in contact with the contact surface becomes larger, and the first output is realized. The resistances received by the terminal 4 and the second output terminal 5 are balanced to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com