Clamping mechanism for drop test machine

A technology of clamping mechanism and testing machine, which is applied in the direction of measuring device, impact test, machine/structural component test, etc. It can solve the problems of single drop test result and difficulty in adjusting the height of drop test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

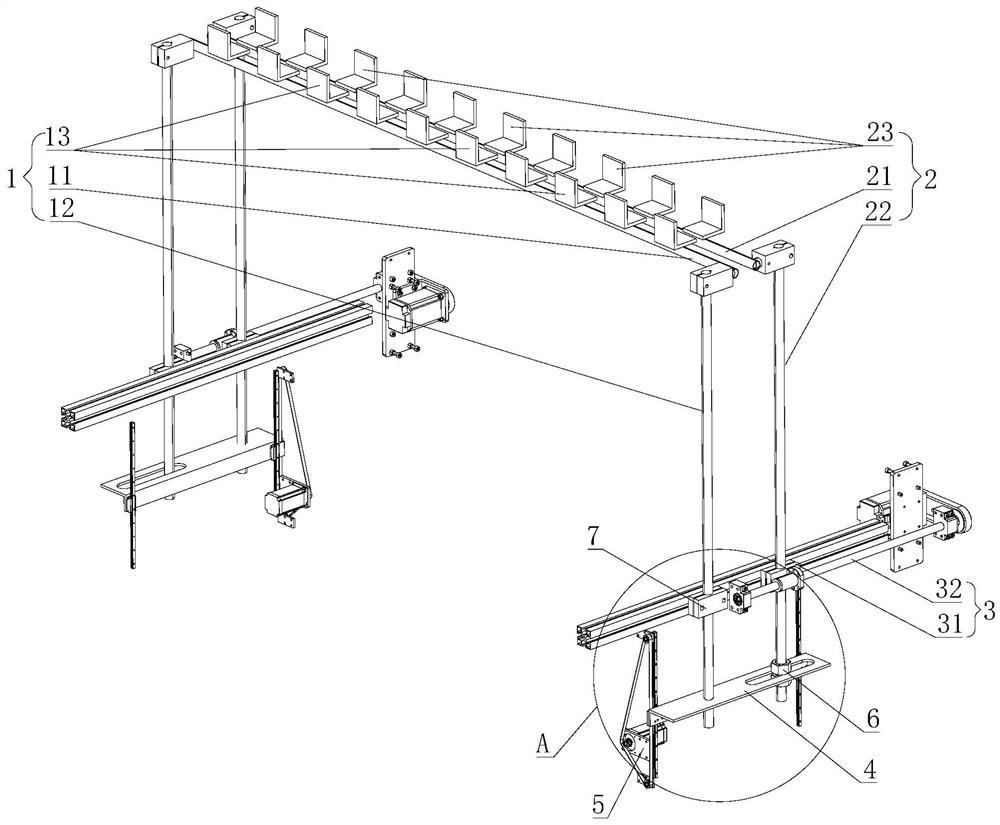

[0022] Such as figure 1 with figure 2As shown, a clamping mechanism for a drop tester provided in this embodiment includes a first clamping group 1, a second clamping group 2 and a horizontal feed mechanism 3, the first clamping group 1 and the second clamping group The two clamping groups 2 are distributed parallel to each other, the power output end of the horizontal feeding mechanism 3 is fixedly connected with the second clamping group 2, and the horizontal feeding mechanism 3 can drive the second clamping group 2 to perform a reciprocating feeding movement, and through the connection with the second clamping group 2 A clamping group 1 cooperates to clamp or loosen the sample to be tested. The horizontal feed mechanism 3 makes a horizontal feed movement, which can drive the second clamping gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com