Universal filter element structure for water purification equipment

A technology of water purification equipment and filter element, which is applied in the direction of fixed filter element filter, filtration separation, filtration treatment, etc., which can solve the problems of high cost of use and maintenance, achieve the effect of improving purification quality and avoiding water backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

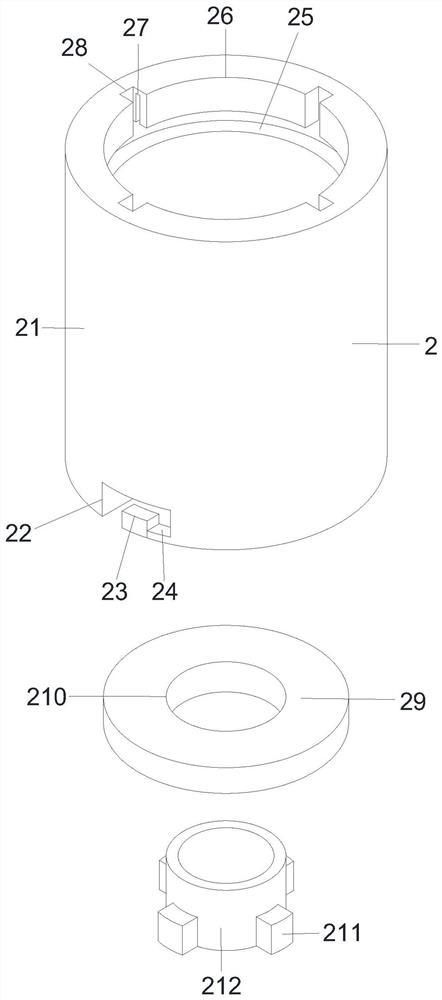

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7, a common filter element structure for water purification equipment, including a movable device 1, the movable device 1 includes a movable cover 16, a block one 14 and a cylinder one 15, and the cylinder one 15 is fixedly arranged on the upper and lower middle parts of the movable cover 16 , the upper ends of the front and rear ends of the inner cylinder surface of cylinder one 15 are all provided with a circular groove one 17, and the bottom of movable cover 16 is provided with an activated carbon filter cartridge 2, the rear surface of stopper one 14 and the annular surface of movable cover 16 The front end of the block is fixedly connected, the middle part of the upper surface of the block one 14 is provided with a rectangular groove one 114, the lower surface of the rectangular groove one 114 is provided with a rectangular groove two 113, and a movable block 111 is arranged in the rec...

Embodiment 2

[0038] refer to Figure 3-7 , a common filter element structure for water purification equipment, which is basically the same as that of Embodiment 1, and furthermore, the difference is that an activated carbon filter cartridge 2 is arranged under the movable cover 16, and a wheat filter cartridge is arranged under the activated carbon filter cartridge 2. Rice stone filter cartridge 4, the bottom of medical stone filter cartridge 4 is provided with activated carbon secondary filter cartridge 5, and the bottom of activated carbon secondary filter cartridge 5 is provided with mineralization ball filter cartridge 6, and the water flow passes through activated carbon filter cartridge 2, Five purification steps of medical stone filter cartridge 4, activated carbon secondary filter cartridge 5, mineralization ball filter cartridge 6 and ceramic sheet filter cartridge 3, through the same connection structure as that between activated carbon filter cartridge 2 and medical stone filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com