Hydrothermal deashing-self-water activation activated carbon preparation device

A technology for the preparation and deashing of activated carbon, which is applied in the fields of inorganic chemistry, carbon compounds, chemical industry, etc., can solve the problems of poor quality, high pollution, low regeneration efficiency, etc., and achieve reduced preparation costs, high specific surface area, and low ash content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

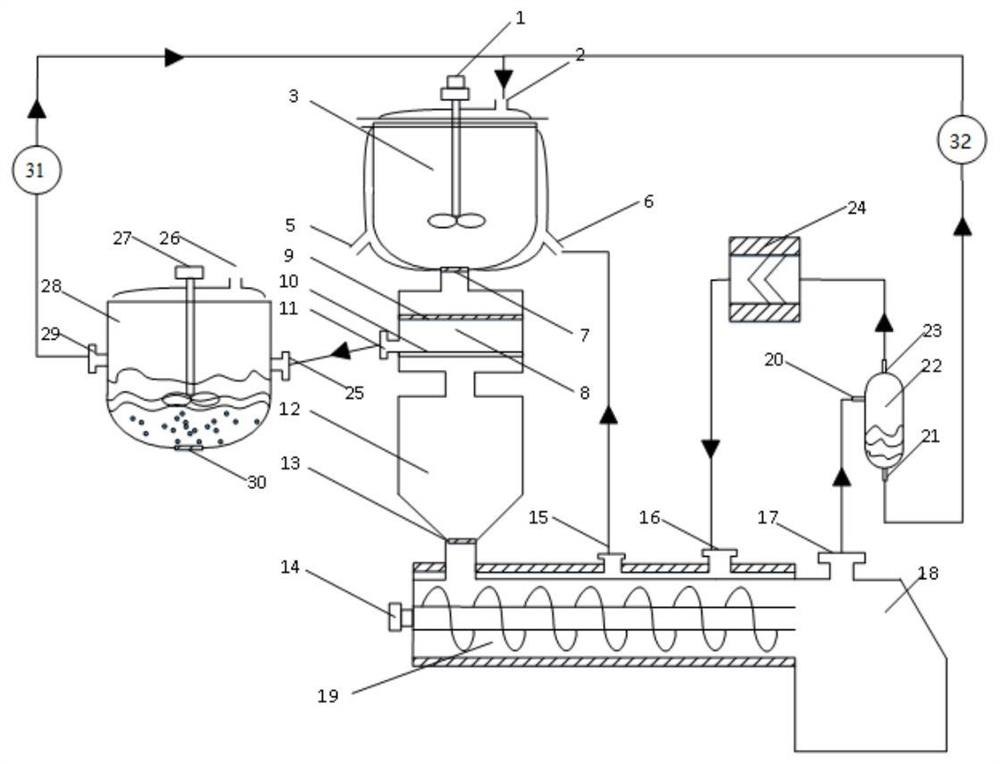

[0013] like figure 1 As shown, the hydrothermal deashing-self-water activation activated carbon preparation device includes a hydrothermal deashing reactor 3 and a pyrolysis activation integrated furnace 19, and the hydrothermal deashing reactor 3 is connected to a solid-liquid separator 8 through a first outlet 7 , the solid-liquid separator 8 is connected to the storage bin 12 through the mixture outlet, and the SiO2 is connected through the filtrate outlet 11. 2 Filtrate inlet 25 on reactor 28, SiO 2 The top of the reactor 28 is provided with a second feed port 26, and the bottom is provided with SiO 2 The material outlet 30 is connected to the first feed port 2 of the hydrothermal deashing reactor 3 through the reactor water outlet 29, and the first water pump 31 is connected between the reactor water outlet 29 and the first feed port 2, The storage bin 12 is connected to the pyrolysis and activation integrated furnace 19 through the second discharge port 13, the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com