Method for preparing active magnesium oxide from carbide slag and preparation method of magnesium cement

A technology of activated magnesia and carbide slag, applied in the direction of magnesia, etc., can solve problems such as land erosion, easy leakage and pollution of road surfaces, and large land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method of magnesium cement, which is based on the calcined product obtained by the above preparation method; then the calcined product, magnesium chloride and water are mixed according to a certain ratio, and the magnesium cement is obtained after curing.

[0049] Among them, the ratio of active magnesium oxide to magnesium chloride is 5-8:1, and magnesium cement is made of MgO-MgCl 2 -H 2 O forms a ternary system, when MgO and MgCl 2 When the ratio is greater than or equal to 5, the hydration product is 518 phase and Mg(OH) 2 ; When MgO and MgCl 2 When the ratio is less than 5, the hydration products are 318 phase and 518 phase. In order to maintain the stability of the 518 phase in the magnesium cement ternary system, the ternary system should contain a certain amount of Mg(OH) 2 , so MgO and MgCl 2 The proportioning ratio is preferably greater than 5.

[0050] It is worth noting that in the actual production pro...

Embodiment 1~6

[0083] The pretreated precursors were calcined at 400°C, 500°C, 600°C, 700°C, 800°C, and 900°C, respectively, and the calcination time was 30 minutes to obtain 6 kinds of calcined products.

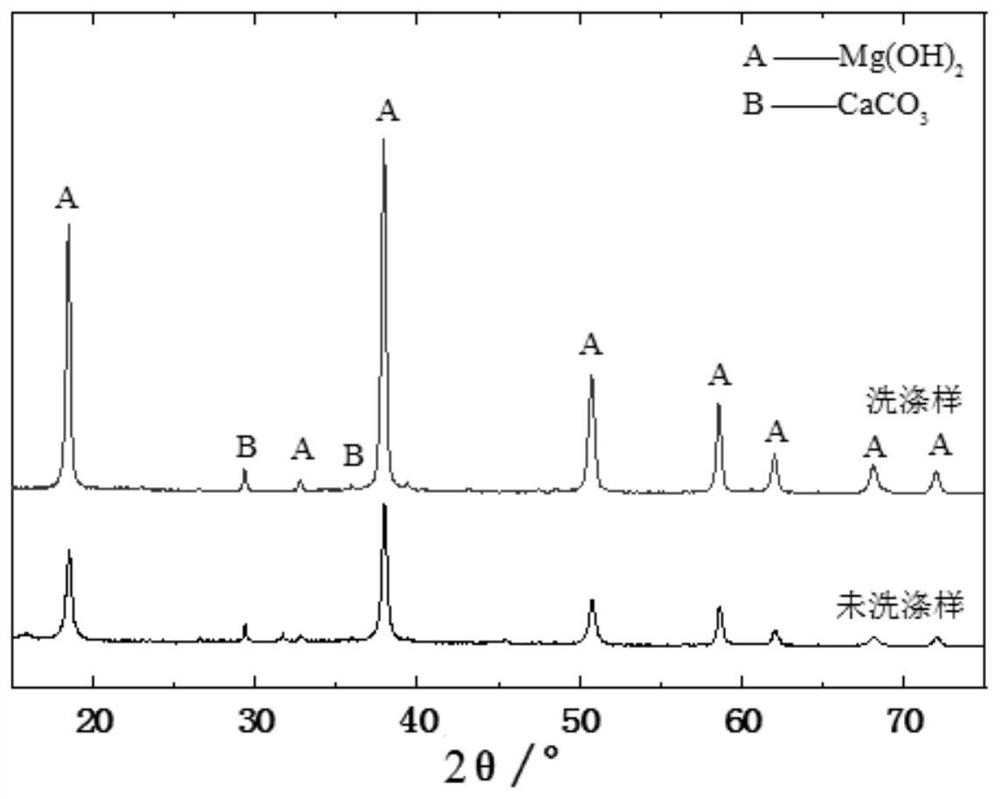

[0084] Carry out XRD analysis respectively to above-mentioned 6 parts of calcined products, obtain spectrum see for details Figure 4 . It can be seen from the figure that the 400°C calcined product of the precursor contains incompletely decomposed Mg(OH) 2 , Mg(OH) in the calcined product at 500°C 2 Characteristic peaks have completely disappeared. It shows that when the temperature is greater than 500°C and calcined for 30 minutes, the Mg(OH) in the raw material 2 It will be completely pyrolyzed to generate MgO, and the reaction formula is:

[0085]

[0086] In addition, by Figure 4 It can be seen that with the increase of calcination temperature, the CaCO 3 The characteristic peaks also tend to decrease gradually. There is obvious CaCO in the calcined product at 500℃ 3 Char...

Embodiment 7~18

[0090] The pretreated precursor was divided into 12 parts and calcined at 400°C, 500°C, 600°C, 700°C, 800°C, and 900°C for 60 min and 90 min, respectively, to obtain 12 different calcined products.

[0091] The mass change curves of the precursors in different calcination conditions measured in Examples 1 to 18 are as follows: Figure 5a shown. It can be seen from the figure that with the increase of calcination temperature, the mass loss rate increases gradually. At 400℃~500℃, the mass loss rate increases significantly with the increase of holding time. The mass loss rate from 500℃ to 900℃ increases slowly with the increase of calcination temperature. From 500℃ to 900℃, the mass loss rate does not change significantly with the extension of the holding time. Therefore, from the perspective of energy consumption, when calcining at 400°C to 500°C, the selection range of holding time is 30min to 90min; when calcining at 500°C to 900°C, the holding time is more suitable for 30m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com