Guide wheel device for railway vehicle and guide wheel position adjusting method thereof

The technology of a rail vehicle and a guide wheel is applied in the field of a guide wheel device for a rail vehicle and the position adjustment of the guide wheel. Longevity, the effect of reducing the inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

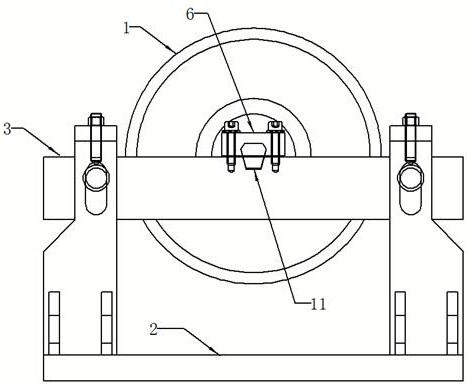

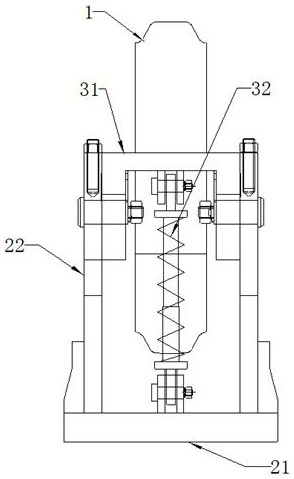

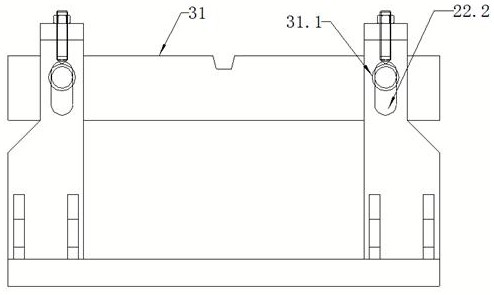

[0030] Attached below Figure 1~5 Embodiments of the present invention are described in detail.

[0031] The guide wheel device for rail vehicles includes a guide wheel 1 that cooperates with the rail to guide the car body, a base 2 connected to the car body, and a vibration damping assembly 3 that elastically supports the guide wheel 1, and is characterized in that the vibration damping assembly 3 It is erected across the front and rear sides of the guide wheel 1 along the direction of the track. The axle 11 of the guide wheel 1 is fixed at the center of the shock absorber assembly 3, and the shock absorber assembly 3 is elastically connected to the base 2. The elastic movement of the vibrating assembly 3 on the base and the track keep guiding cooperation.

[0032] In the guide wheel device for rail vehicles described above, the shock absorbers in the prior art are arranged on both sides of the guide wheel in the axial direction, and the vibration damping assembly 3 is chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com