Structure for supporting and crossing of water-stop curtain through old bottom plate obstacle, and construction method of structure

A water-stop curtain and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems affecting the foundation of old houses around, large soil extrusion, and difficult pouring piles, etc., and achieve good promotion and application The effect of value and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

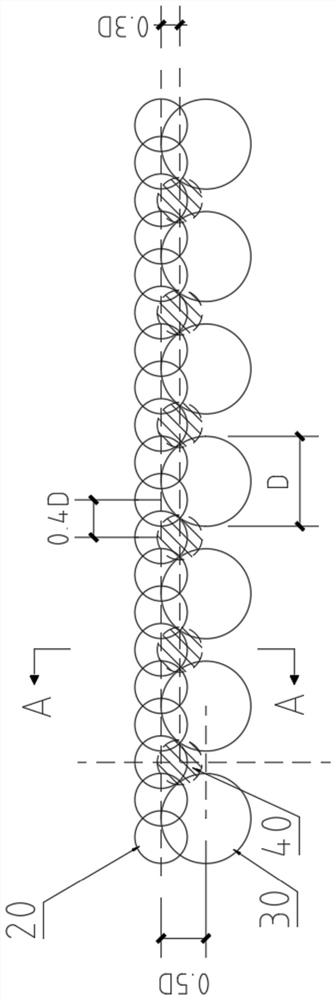

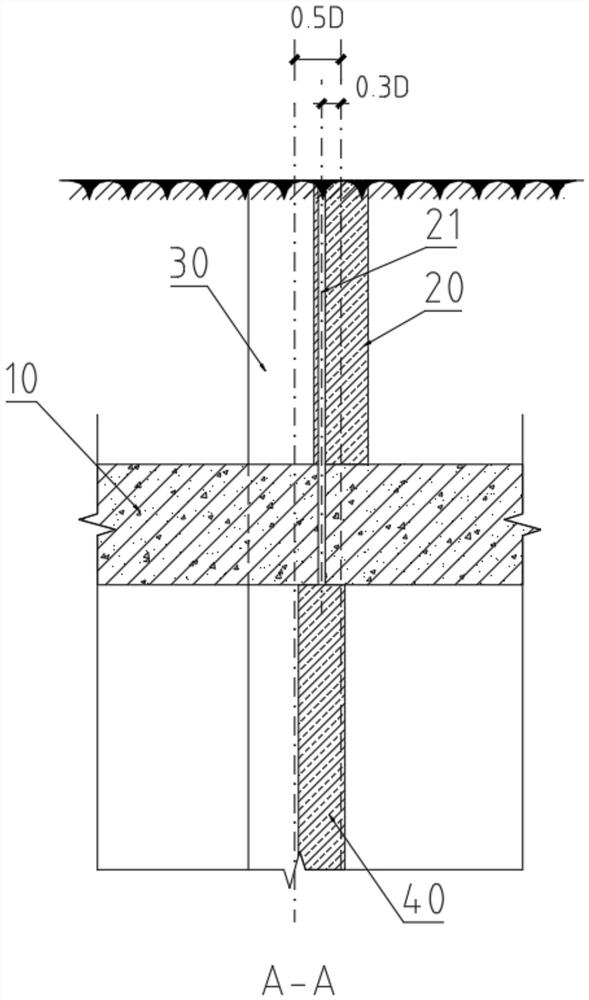

[0029] see figure 1 with figure 2 , the structure of a support and water-stop curtain passing through the old floor barrier of the present embodiment, including a basement floor barrier 10 with a thickness of 1 meter, cement mixing and interlocking row of piles 20, pouring row of piles 30 and several high-pressure jet grouting piles 40;

[0030] Specifically, the cement mixing and interlocking row of piles 20 is arranged around the edge of the foundation pit, and the bottom of the cement mixing and interlocking row of piles 20 extends downward to the top surface of the old basement floor barrier 10;

[0031] More specifically, the cement mixing pile row 20 is composed of several cement mixing piles;

[0032] Specifically, the grouting row of piles 30 is arranged around the edge of the foundation pit, the grouting row of piles 30 extends downward from the ground to the bottom of the old basement floor barrier 10, and the grouting row of piles 30 is located on the inner side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com