Washing machine with lifting impeller inner barrel

A washing machine and inner tub technology, applied in the field of washing machines, can solve problems such as labor and waist fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

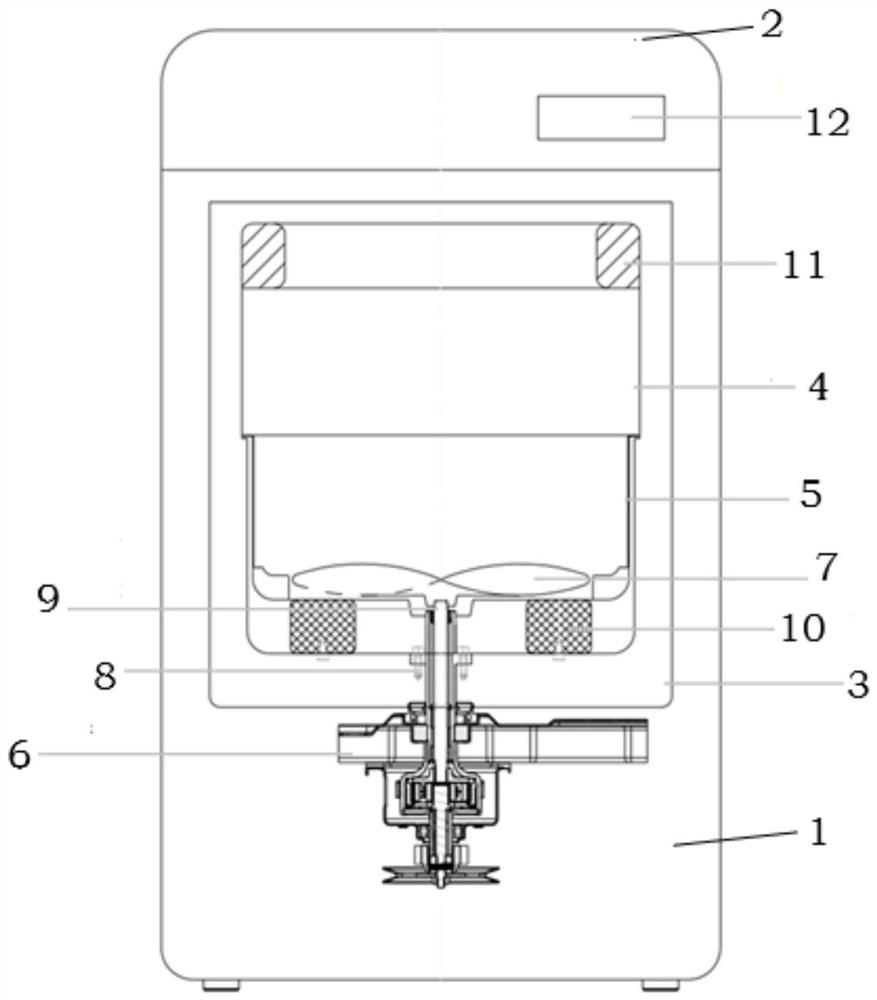

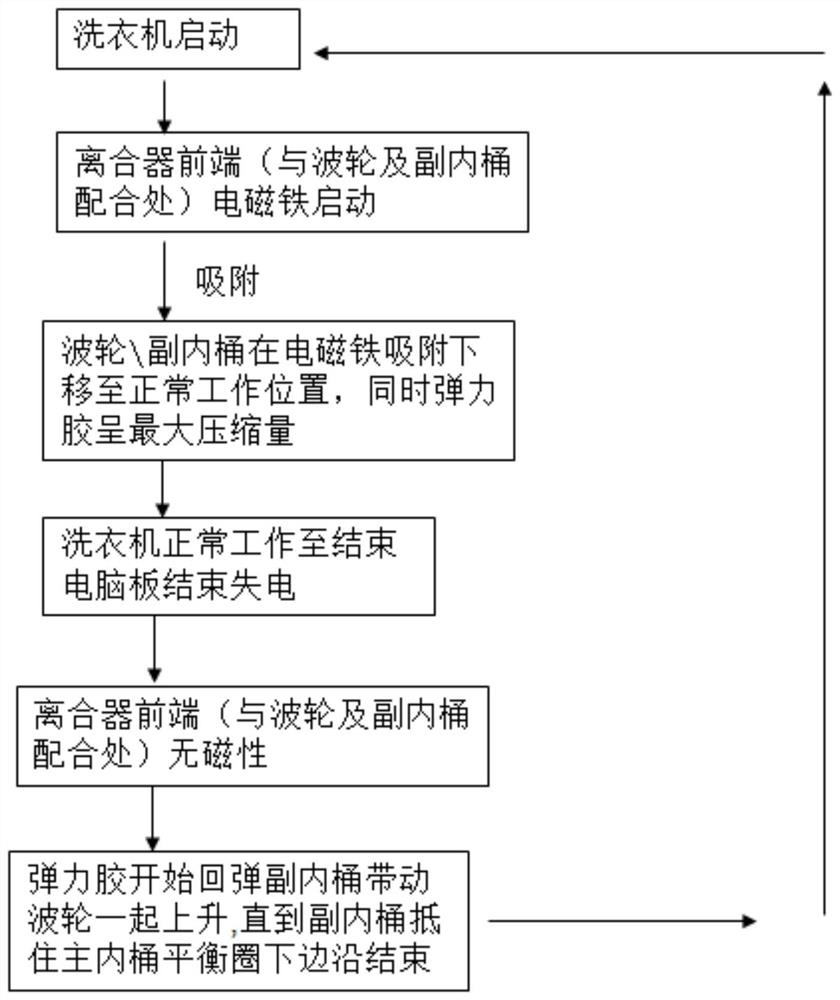

[0012] The washing machine of the present invention with a pulsator and an inner barrel that can be raised includes a box body 1 and a top cover 2 installed on the box body 1. An outer tub 3, a main inner tub 4, a secondary inner tub 5, a clutch 6, and a pulsator 7 are installed in the box body 1. The main inner tub 4 is located in the outer tub 3 and the bottom of the main inner tub 4 is spaced apart from the bottom of the outer tub 3 . The auxiliary inner tub 5 is located at the lower section of the main inner tub 4 , and the bottom of the auxiliary inner tub 5 is spaced apart from the bottom of the main inner tub 4 . The clutch 6 is screwed to the center of the outer barrel 3 and its front end shaft passes through the outer barrel 5 and the main inner barrel 4 and then extends into the auxiliary inner barrel 5 . The main inner barrel 4 is fixedly connected with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap