Gluing and folding device for super large corrugated paper printing line

A folding device, corrugated paper technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of large size corrugated board, difficult manual operation, low production efficiency, etc., to achieve flexible use, stable transportation, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

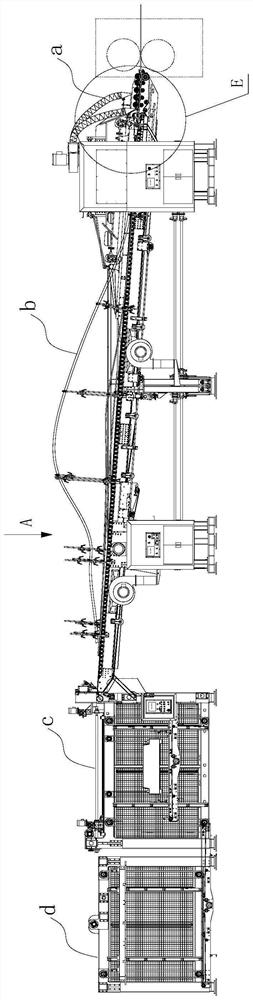

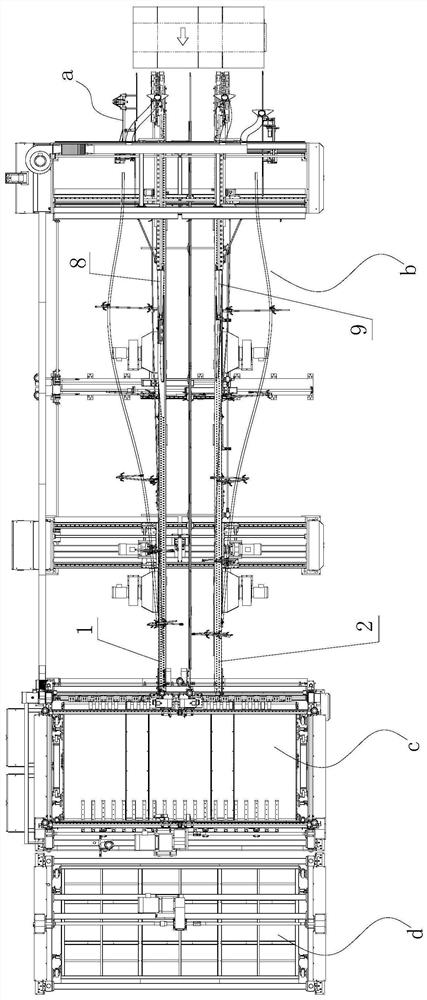

[0051] The present embodiment is a folder gluing and folding device for a super-large corrugated paper printing linkage line, such as figure 1 or figure 2 As shown, it includes a gluing part a, a folding part b, a counting discharge part c and a pressing part d which are connected in sequence. In this device, the input end of the folding mechanism is connected to the printing and die-cutting part of the super-large corrugated paper printing linkage line, that is, after the cardboard is printed and die-cut, it enters the device for gluing, folding, counting and discharging, pressing, and finally presents The super-large corrugated paper printing linkage is sent out in a stack.

[0052] The specific structures of the above parts are as follows:

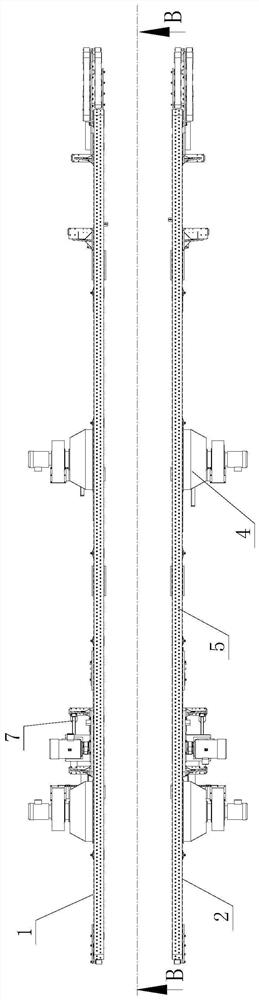

[0053] 1. Folding box

[0054] The box folding part includes a cardboard conveying mechanism and a folding mechanism. Along the cardboard conveying direction, the gluing part and the folding mechanism are sequentially arranged above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com