Edge strip and method for production thereof

An edge strip and edge technology, applied in the field of edge strips, can solve problems such as uneven decoration, and achieve the effect of improving visual impression, uniform transition and reducing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

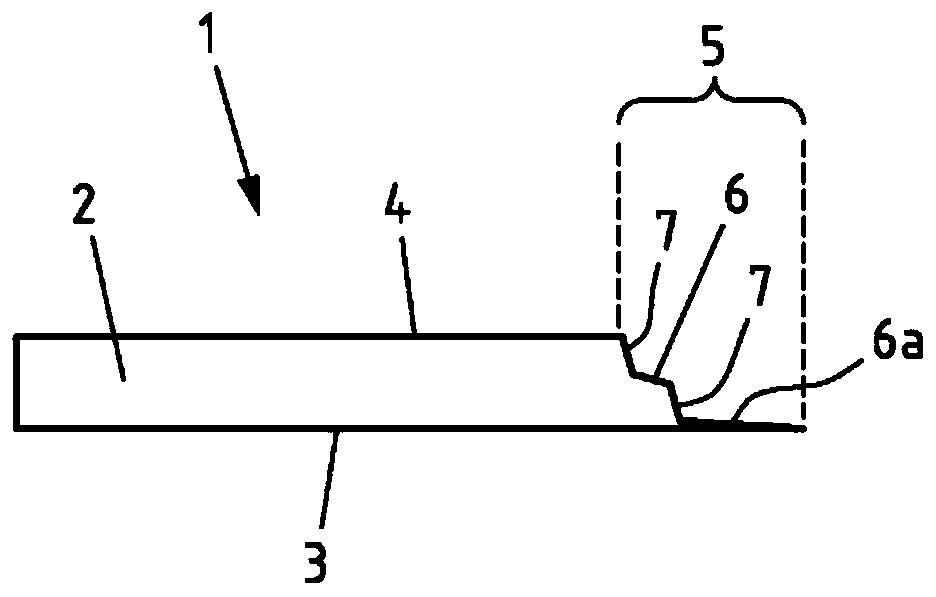

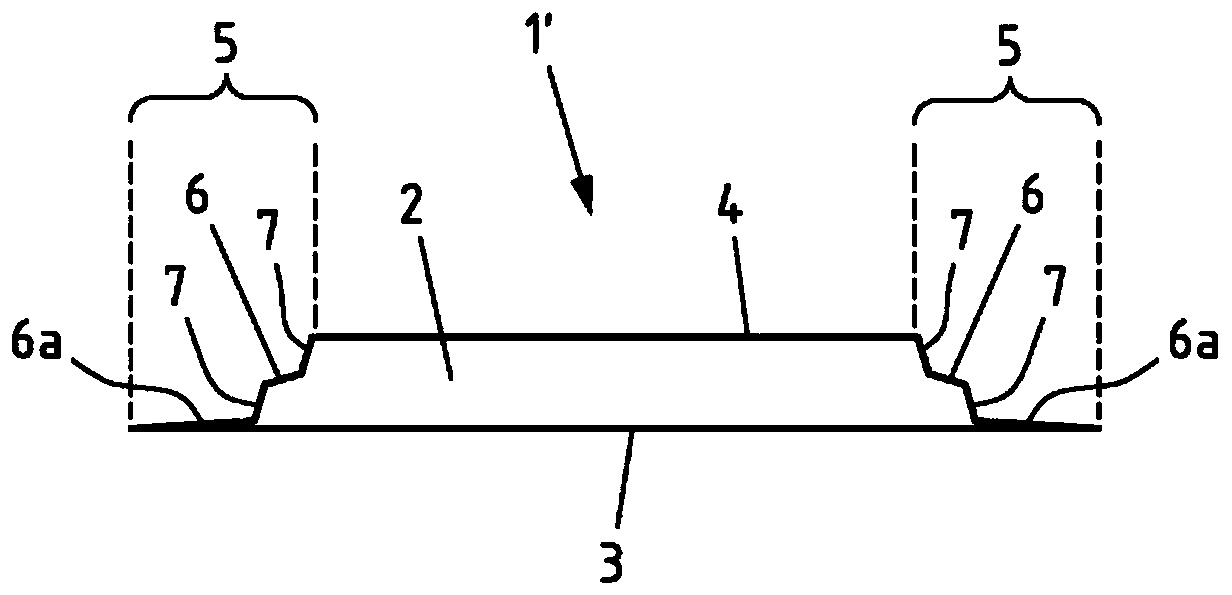

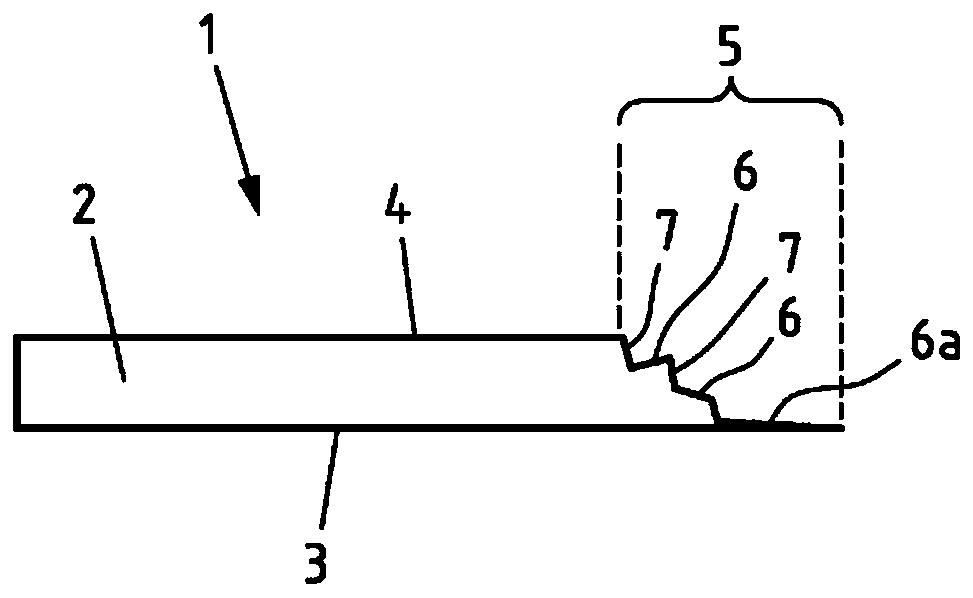

[0114] exist Figures 1a to 1e and 2, a side view of a preferred embodiment of the edge strips 1 and 1' is shown by way of example, and the edge strip 1 is shown in a three-dimensional view in which the top side of the first step is wider than the top side of the subsequent steps. Figure 3a to Figure 3c show Figure 1a to Figure 1e and figure 2 Preferred embodiment of the edge strip 1 in which the top side of the first step is also wider than the top side of the subsequent steps, but with Figures 1a to 1e and figure 2 The edge strip has more steps than the edge strip in and is attached to the furniture. Figure 4 , 5 and 6 show different designs of the method according to the invention. Figure 7 An embossing roll according to the invention is shown. Figure 8a to Figure 8c show Figure 3a to Figure 3c A variant of the edge strip with a rounded transition section 5. Figure 9a to Figure 9c show Figure 8a to Figure 8c The ladder of the edge strip has a wave-shaped va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com