Coal-pillar-free mining and gas treatment method for high-gas coal seam

A technology without coal pillars and gas, which is applied in gas discharge, ground mining, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

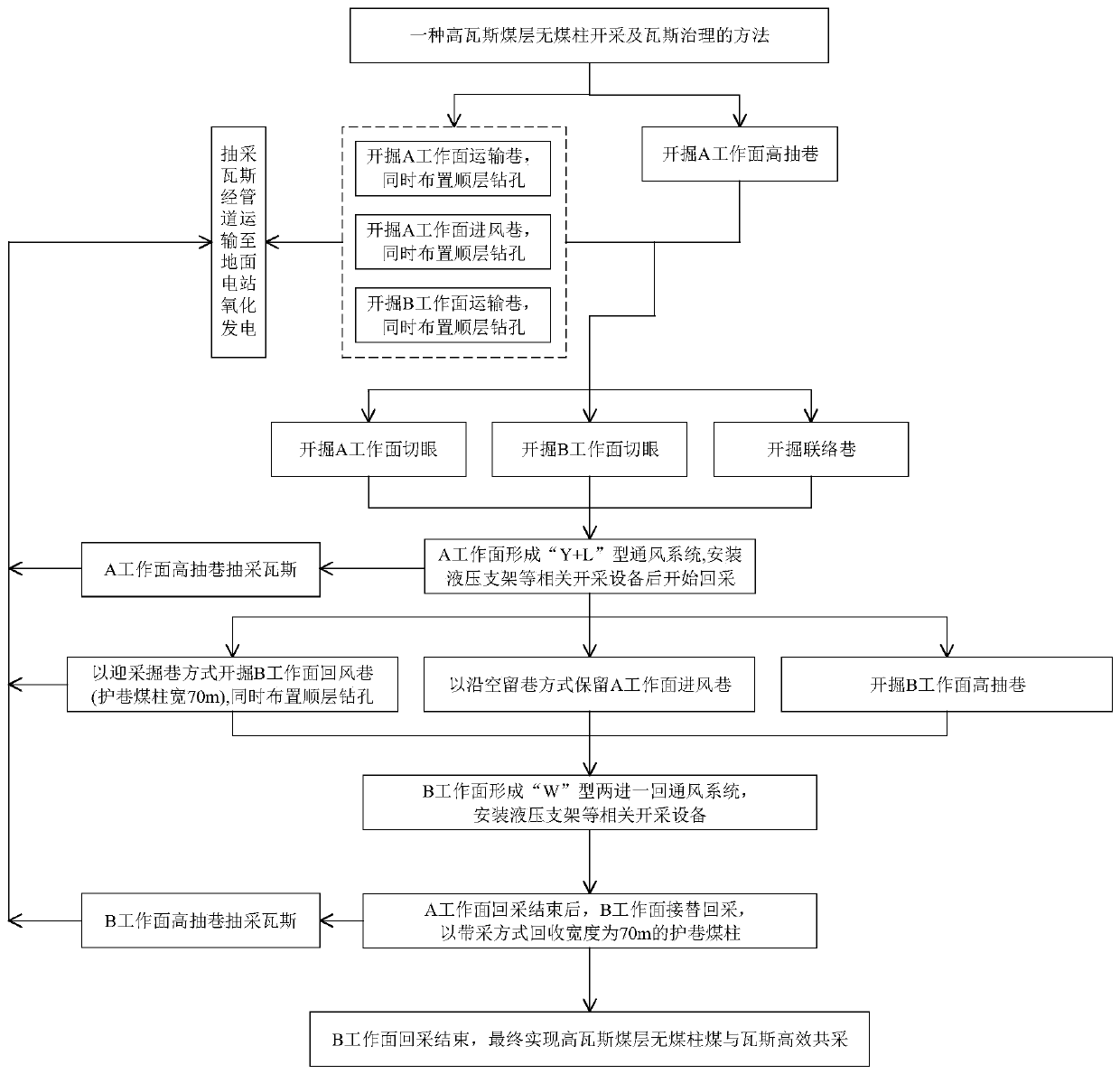

[0021] Such as Figure 1 to Figure 5 Shown, a kind of high gas coal seam non-pillar mining of the present invention and the method for gas control are characterized in that concrete steps are as follows:

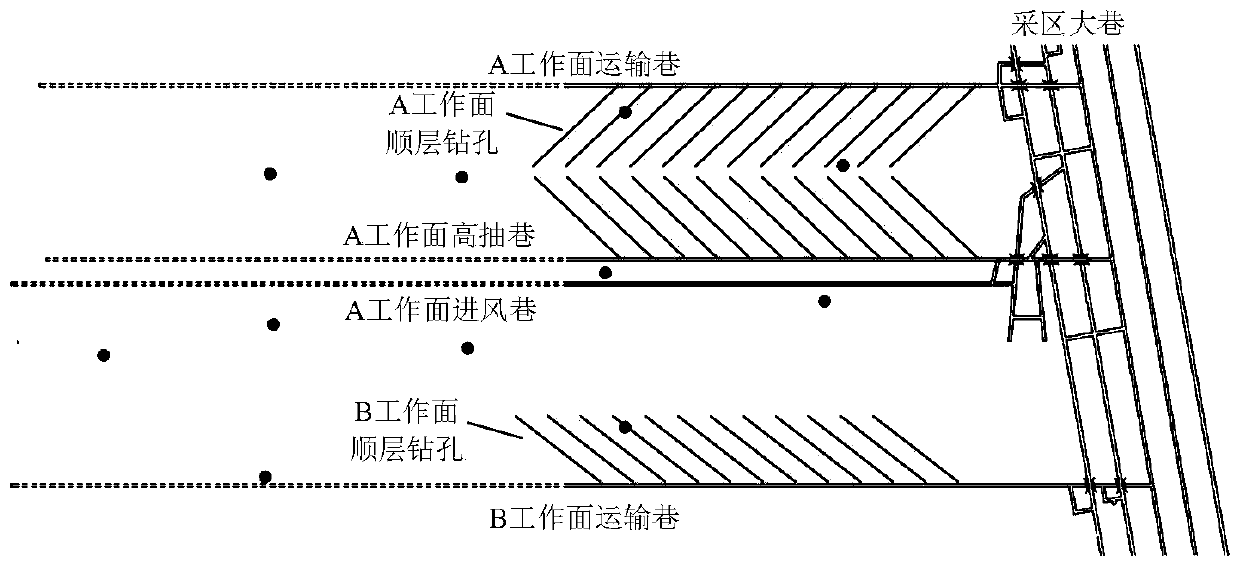

[0022] a First excavate the coal lanes on both sides of the working face A as the transport lane, the coal lane as the air inlet lane and the rock lane in the roof as the high extraction lane, and simultaneously excavate the coal lanes on the working face B as the transport lane, each coal lane During the excavation, use the drilling rig to drill bedding holes into the pre-mined coal body at the side of the roadway following the excavation face, and pre-extract the gas in the unmined coal body of the two working faces through the bedding holes to reduce the gas content of the mined coal seam ;

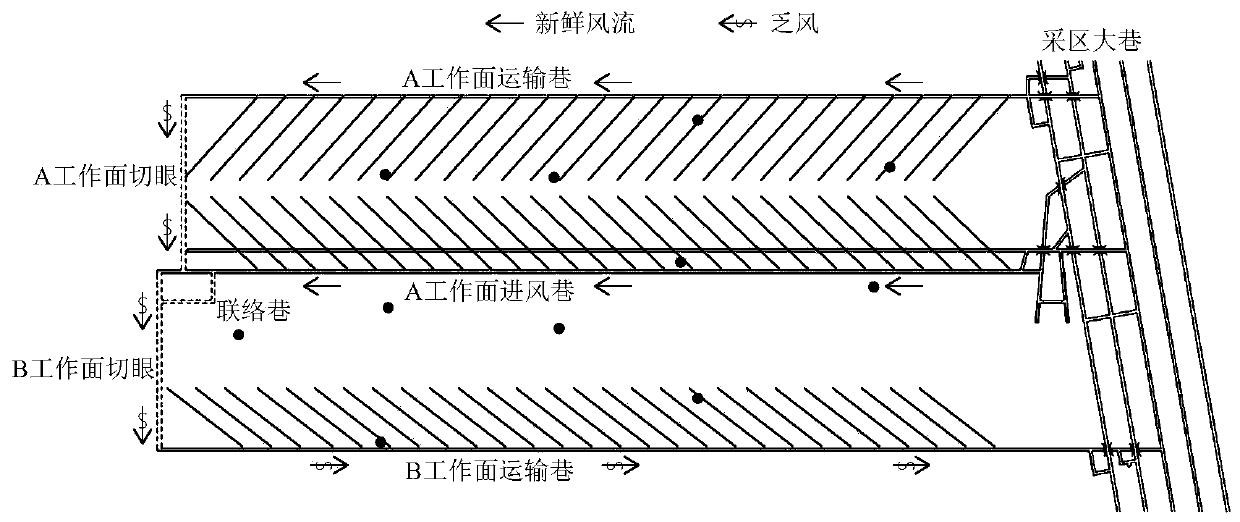

[0023] b After the above-mentioned roadway layout is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com