Quick-release box body of inspection robot

A technology for inspection robots and boxes, applied in the field of robots, can solve the problems of material waste, time-consuming and laborious, etc., and achieve the effect of extending the flameproof length, reducing consumables, and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

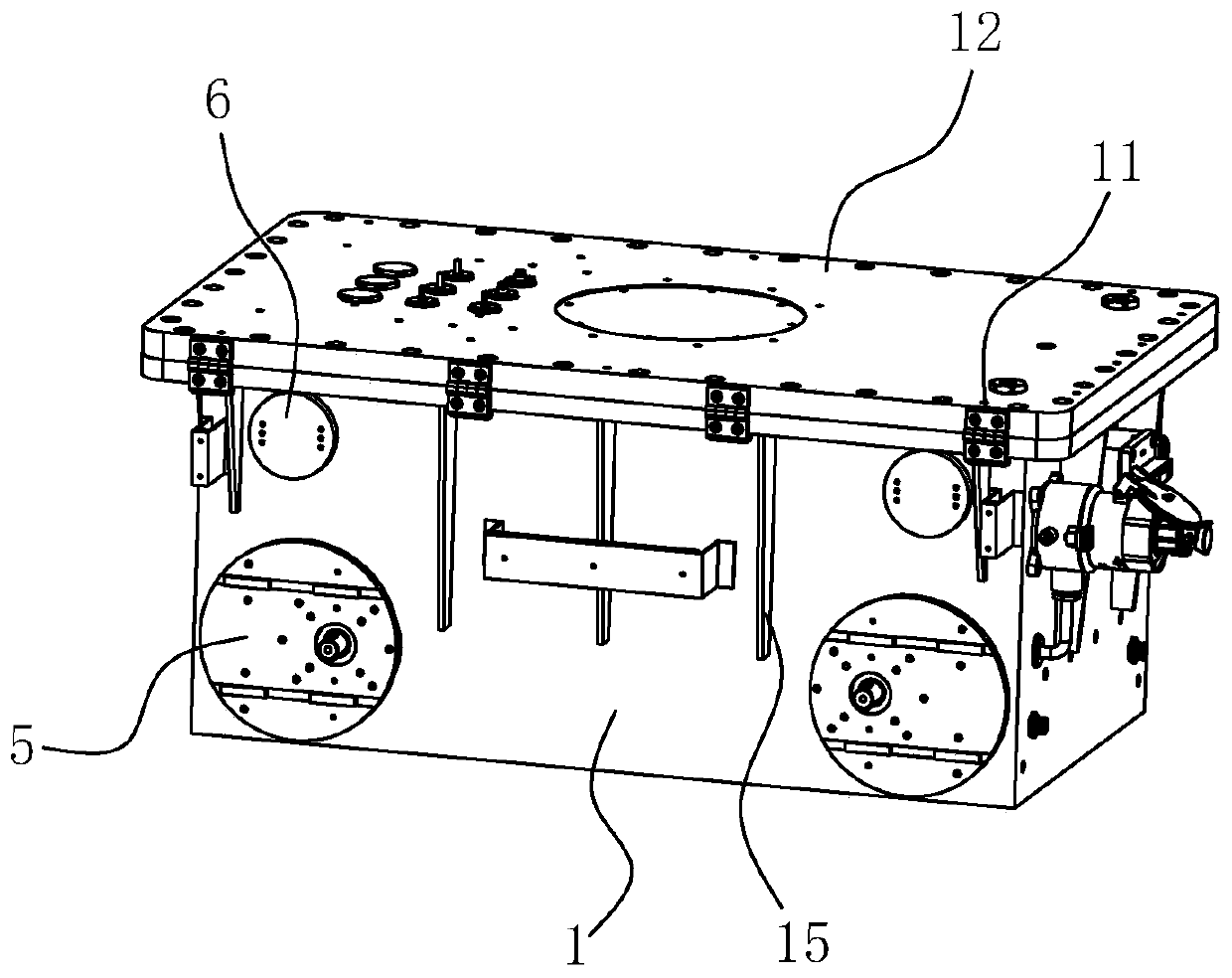

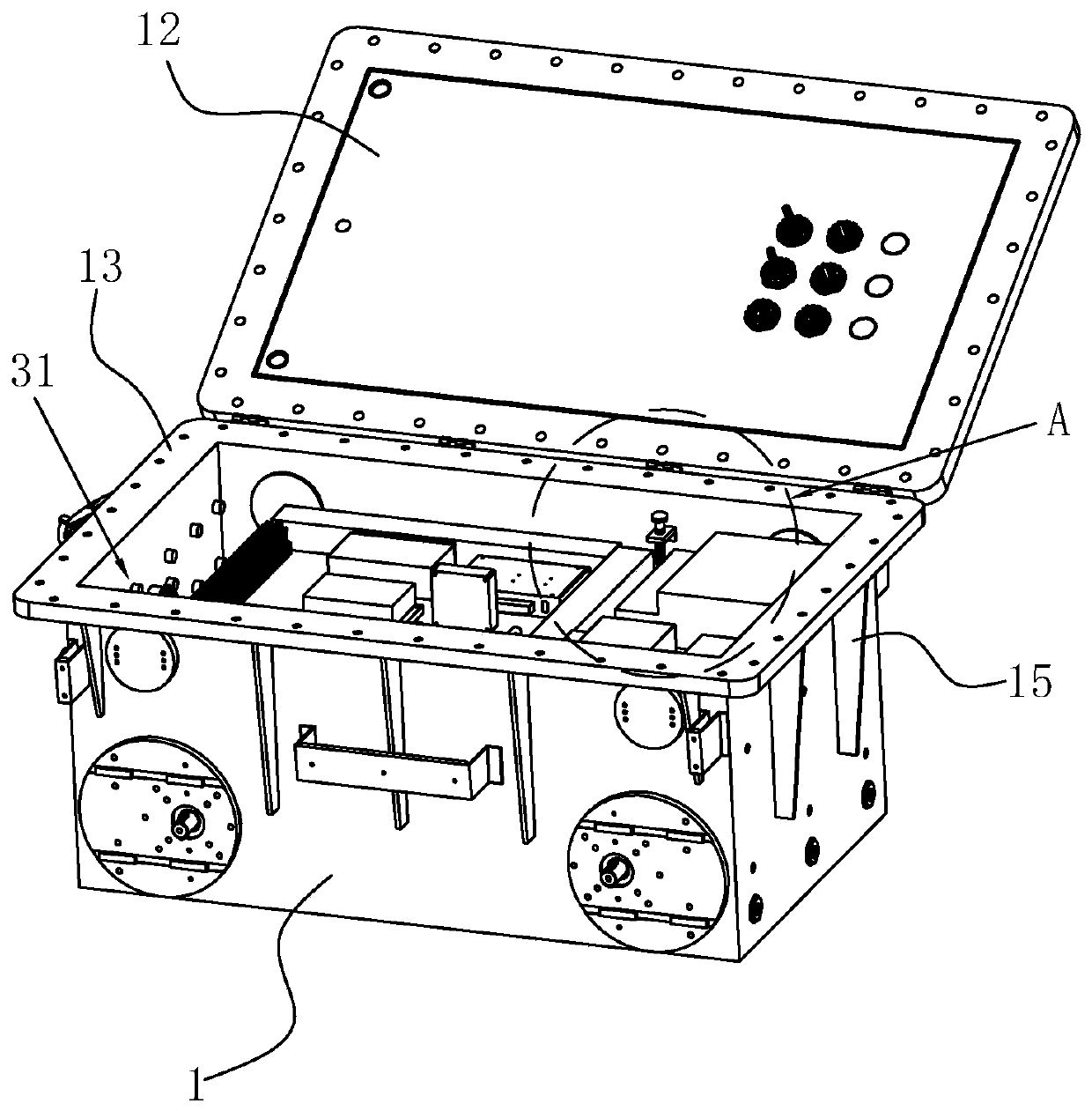

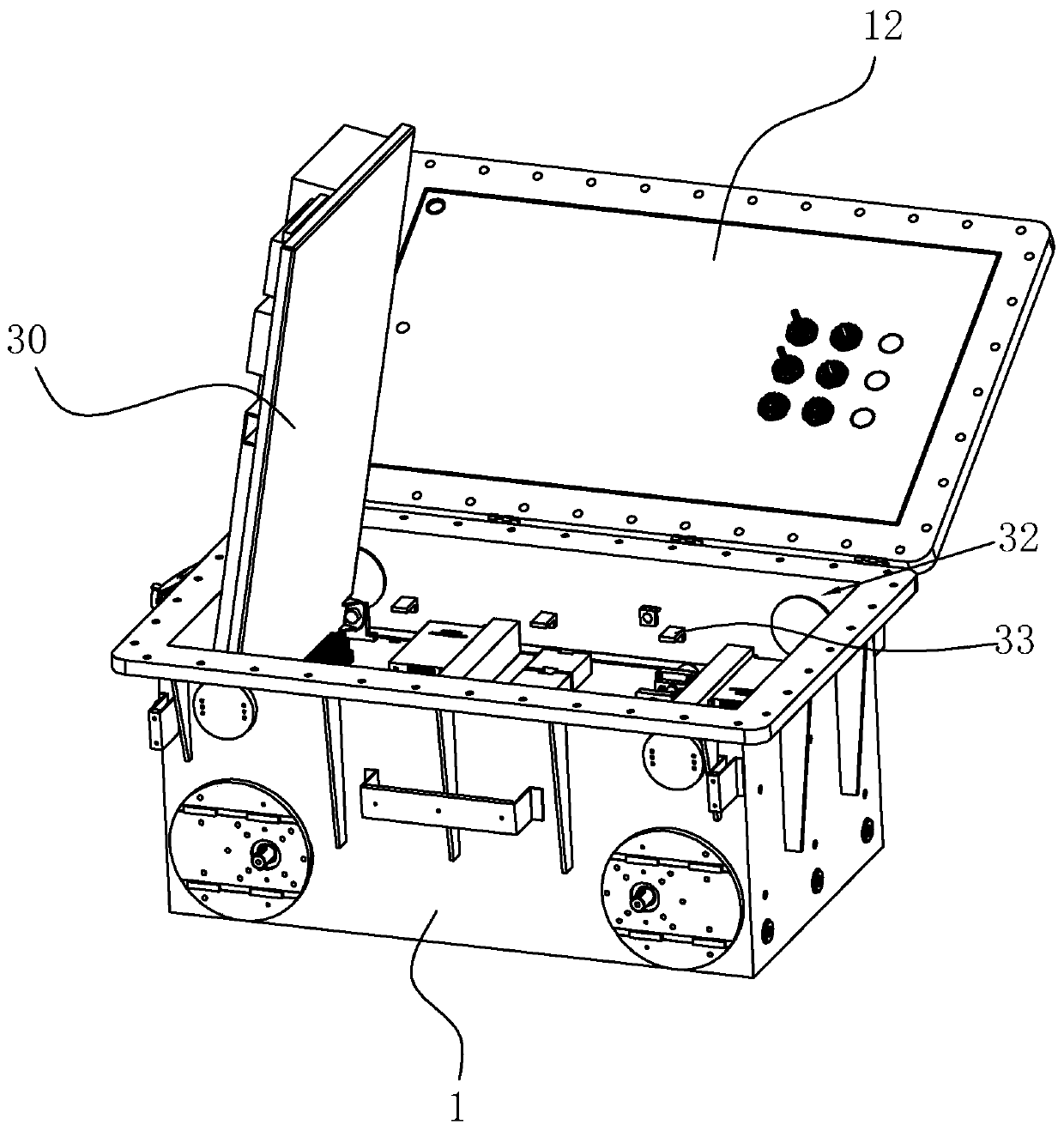

[0032] The inspection robot quick release box body disclosed by the present invention, such as figure 1 As shown, it includes a box body 1 with an opening at the top and a cover plate 12 covering the opening position of the box body 1. The box body 1 is the body of the inspection robot, and its interior is integrated with tasks such as controlling the movement and detection of the inspection robot. At the same time, the box body 1 is connected to the driving device (driving wheel, etc.) that drives the movement of the inspection robot, as well as various detection and sensing equipment and information collection equipment. Such as figure 1 with figure 2 As shown, the cover plate 12 is hingedly connected to one side of the box body 1 through a hinge 11. Therefore, only the cover plate 12 needs to be turned over during maintenance, and there is no need to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com