Landfill solidified fly ash landfill operation dust prevention and dustfall system and implementation scheme

A landfill, fly ash technology, applied in chemical instruments and methods, excavation, smoke removal, etc., can solve the problems of aggravated dust and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

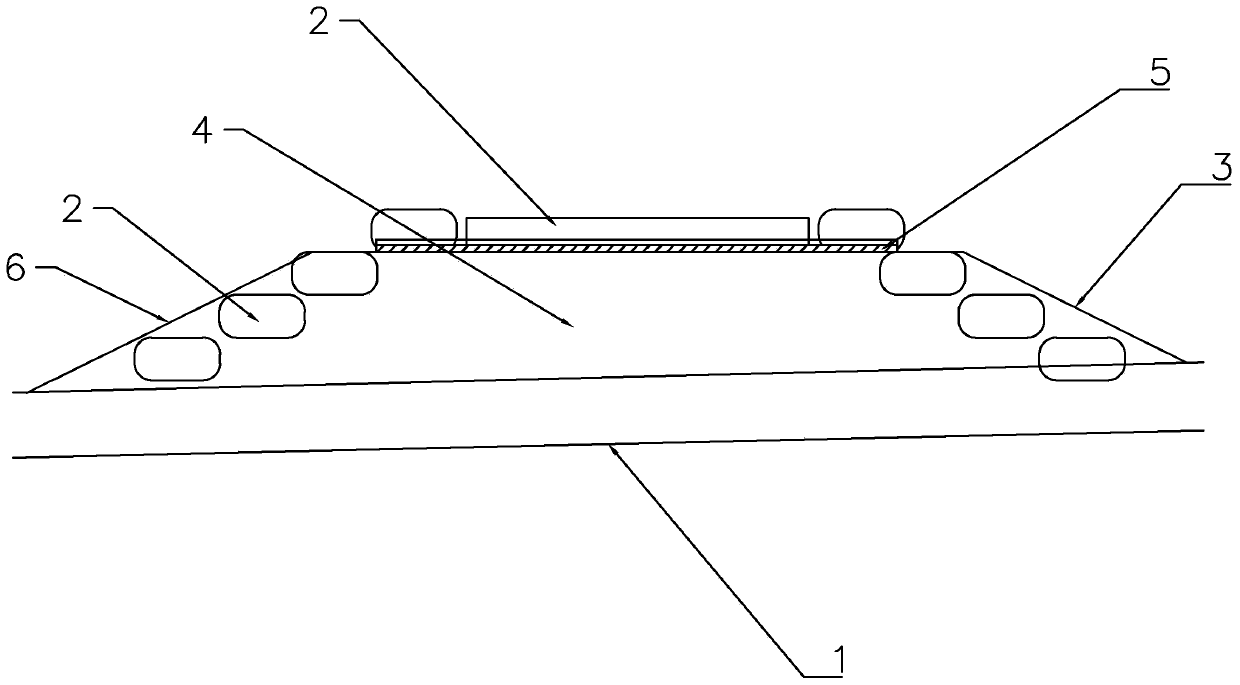

[0015] Such as figure 1 As shown, a landfill solidified fly ash landfill operation dust prevention and dust suppression system includes a temporary operation road 1, a discharge platform 6, and a sprinkler set up along the surrounding road according to the height of the solidified fly ash landfill pile , fog bubbles, the temporary operation road 1 and the unloading platform 6 include a roadbed steel plate box 2, an HDPE film cover 3, a granular solidified fly ash pile 4 and a geotextile 5, and the HDPE film cover 3 is welded to form a seal Membrane cover.

[0016] The dust prevention and dust suppression system for the solidified fly ash landfill operation in the landfill consists of a temporary operation road 1, an unloading platform 6, a sprinkler, and fog bubbles, and the temporary operation road 1 and the unloading platform 6 include a roadbed steel box 2, HDPE film Cover 3, granular solidified fly ash pile 4 and geotextile 5, cover the granular solidified fly ash pile 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com