A production system for welding h-shaped steel

A production system, H-shaped steel technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex operation procedures, high labor intensity, low assembly and welding efficiency, etc., to achieve simple operation procedures, reduce The effect of labor intensity and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

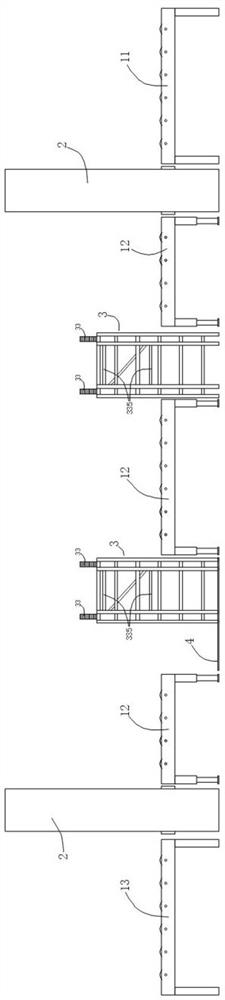

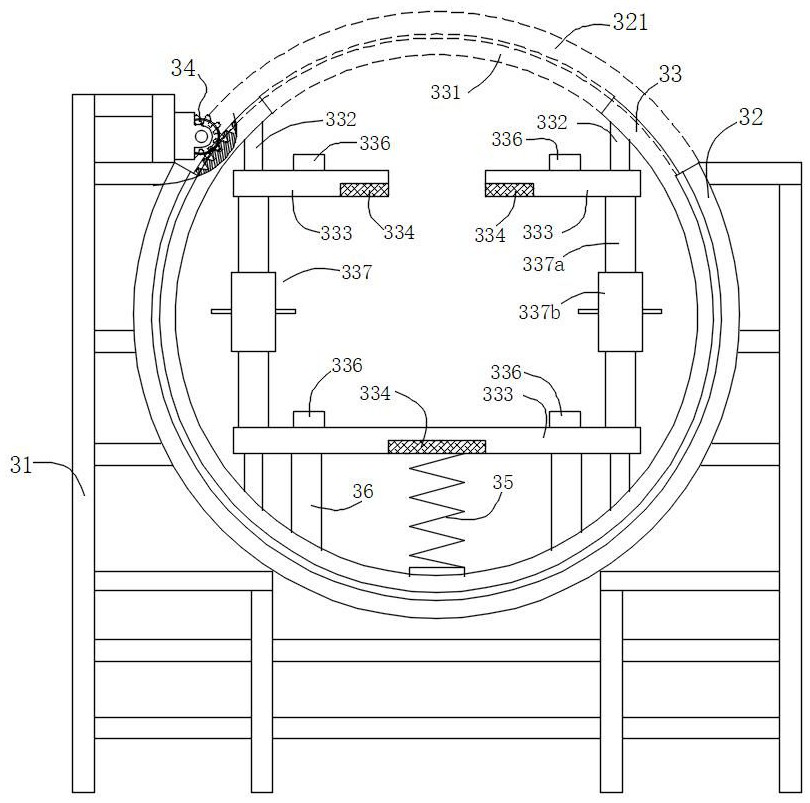

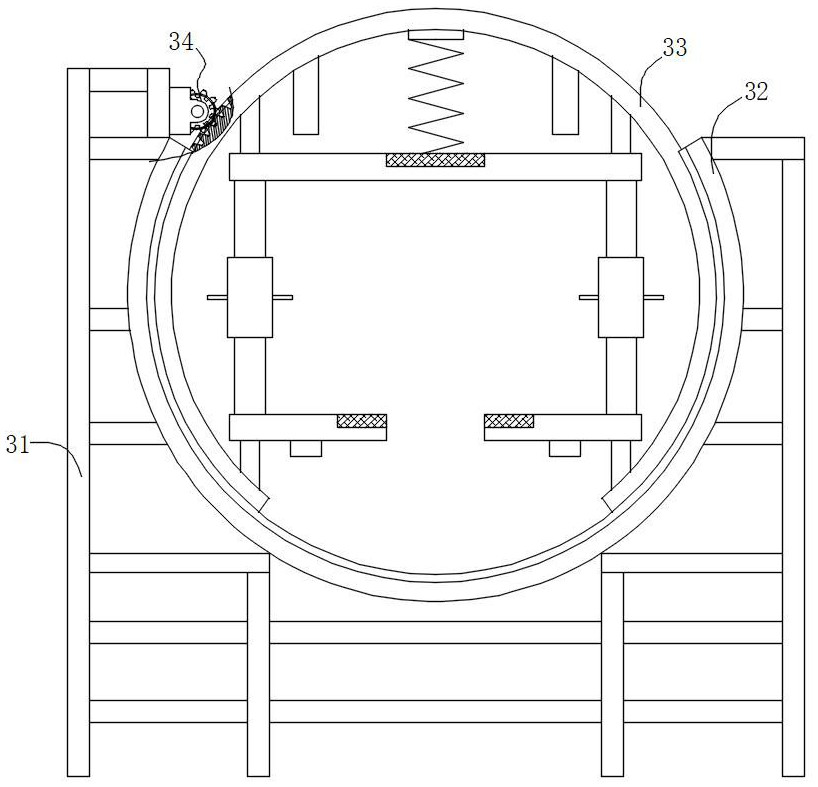

[0026] like figure 1 As shown, a production system for welding H-shaped steel includes a conveying roller 1, a setup device 2 and a flip device 3 for flip H-shaped steel; the setup machine 2 and the flip device 3 are along the conveyance. There are two in the conveying direction of the roller 1, and both of the flippers 3 are between two of the setup machines 2; the spacing between the two sets of setsters is greater than the H-type steel to be welded. The maximum length, and the spacing of the two flip device 3 is smaller than the minimum length of the H-shaped steel to be welded; the conveying roller 1 includes a first conveying roller 11, a second conveying roller 12, and a third transport roller 13, said The first conveying roller 11 and the third conveying roller 13 are respectively disposed on both sides of the two of the setup machine 2, wherein the first conveying roller 11 is disposed in a leading group in the conveying direction. On the input side of the stand 2, the thi...

Embodiment 2

[0049] In the present embodiment, the main structure is the same as that of the third embodiment, and will not be described later, the main difference between the embodiment and the first embodiment is:

[0050] The lock adjustment mechanism 337 includes two support sleeves 337a set on the support rod 332, and both support sleeve 337a can move in the longitudinal direction of the support rod; one end of the two support sleeve 337a The opposite connection thread is rotated and connected by a threaded adjustment sleeve 337b. The support rod 332 has a limit slot disposed in the longitudinal direction, the support sleeve having a limiting screw disposed in the radial direction, and the end of the limiting screw remissions into the limit slot. Inside.

[0051] The two of the two support portions 333 are mounted at both ends from the two support sleeve 337a to each other, and are located in the support rod away from the two support portions of the second gap. The laminate differs from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com