An Eccentric Adjustment Method for Helical Milling Holes

A technology of helical hole milling and eccentric adjustment, applied in the field of hole making processing, can solve the problems of difficult to achieve micro adjustment of eccentric amount, affecting the accuracy of eccentric amount adjustment, unqualified machining aperture, etc., so as to increase the machining aperture range and improve machining Quality, the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

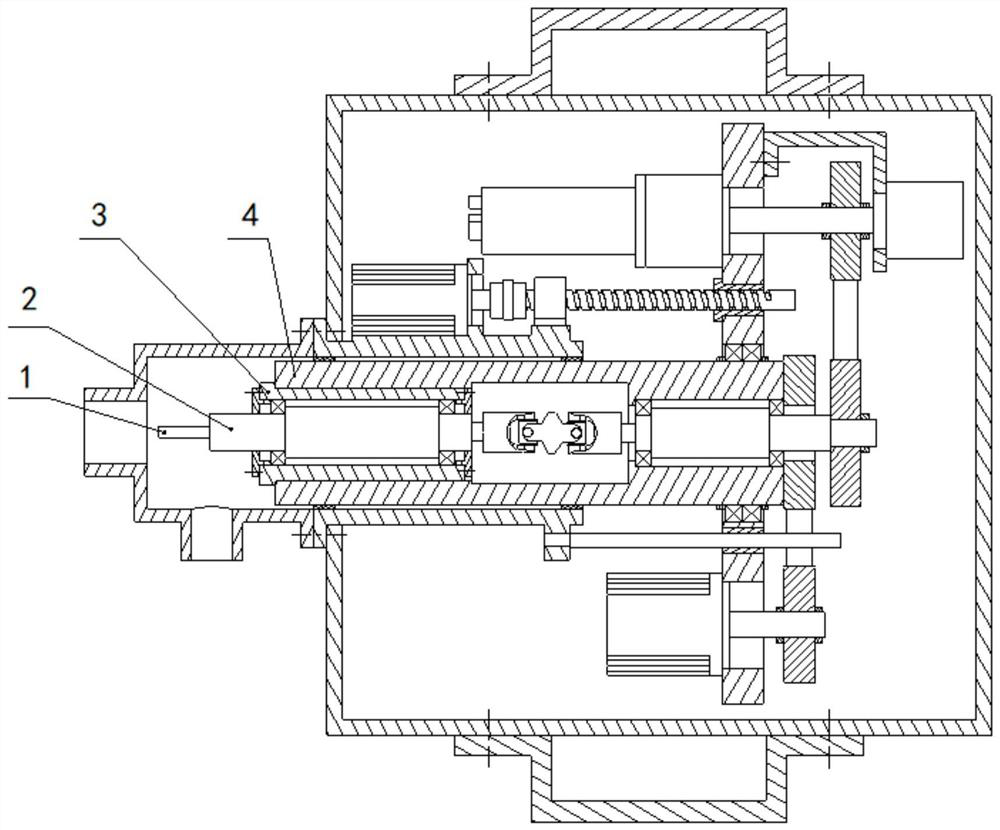

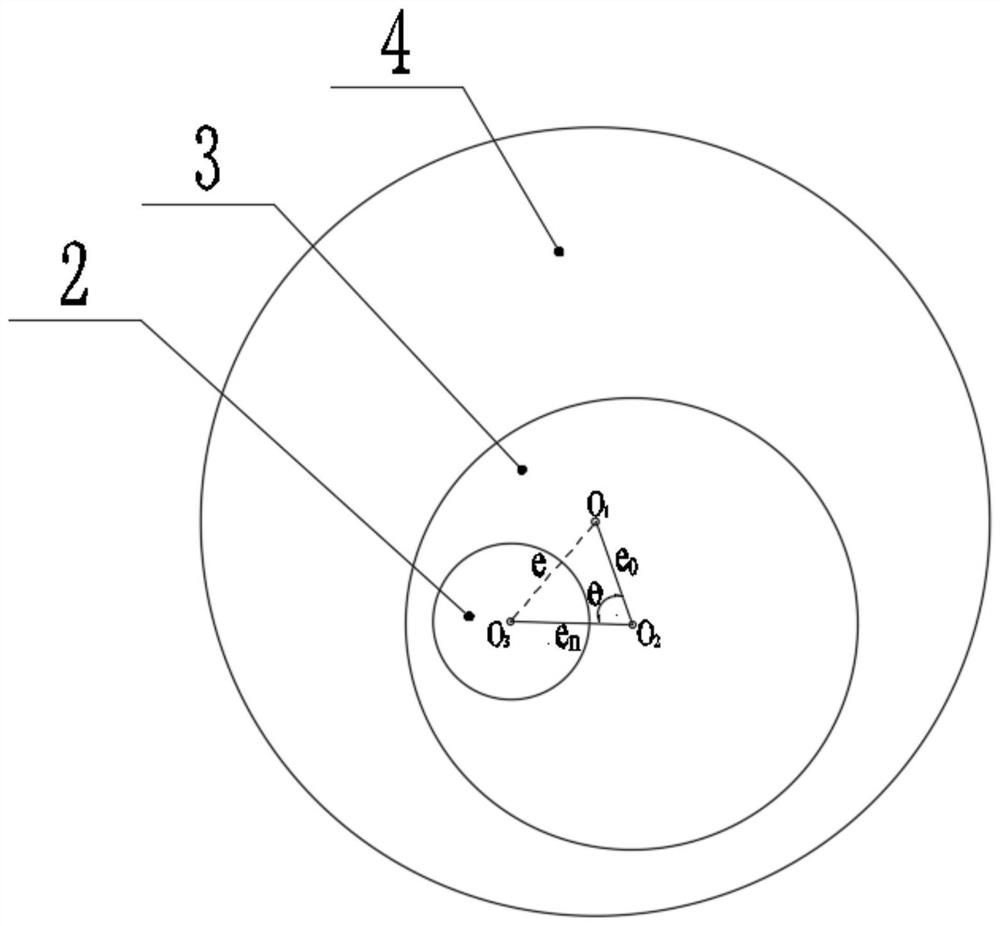

[0054] In this embodiment, the eccentricity e of the outer sleeve 4 of the helical milling device 0 =0.5, use the φ8 milling cutter to process the φ10 and φ13 holes, the specific processing steps are as follows:

[0055] S1. Select the eccentricity of an outer sleeve 4 as e 0 =0.5, the eccentricity of the 4 eccentric main shafts are respectively e n = 0.5, 1.5, 2.5, 3.5;

[0056] S2, according to e in step S1 0 = 0.5 and e n =0.5, 1.5, 2.5, 3.5, calculate the corresponding eccentricity e n = 0.5, 1.5, 2.5, 3.5 The eccentricity adjustment range e of the helical milling device of the eccentric spindle a ~e b , the eccentric adjustment ranges corresponding to the four eccentric spindles are: [0,1], [1,2], [2,3], [3,4];

[0057] S3. According to the current diameter of the hole to be processed D=φ10 and the diameter of the tool 1 to be processed d=φ8, calculate the theoretical value of the eccentricity adjustment required by the helical milling device e=(D-d) / 2=1;

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com