Boarding tower of cruise ship construction tool

A technology for boarding towers and cruise ships, applied in the field of boarding towers, can solve the problems of wasted man-hours, small transportation volume, and small transportation volume of stairs, and achieve the effects of simple and fast operation, reduced labor costs, and reliable detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

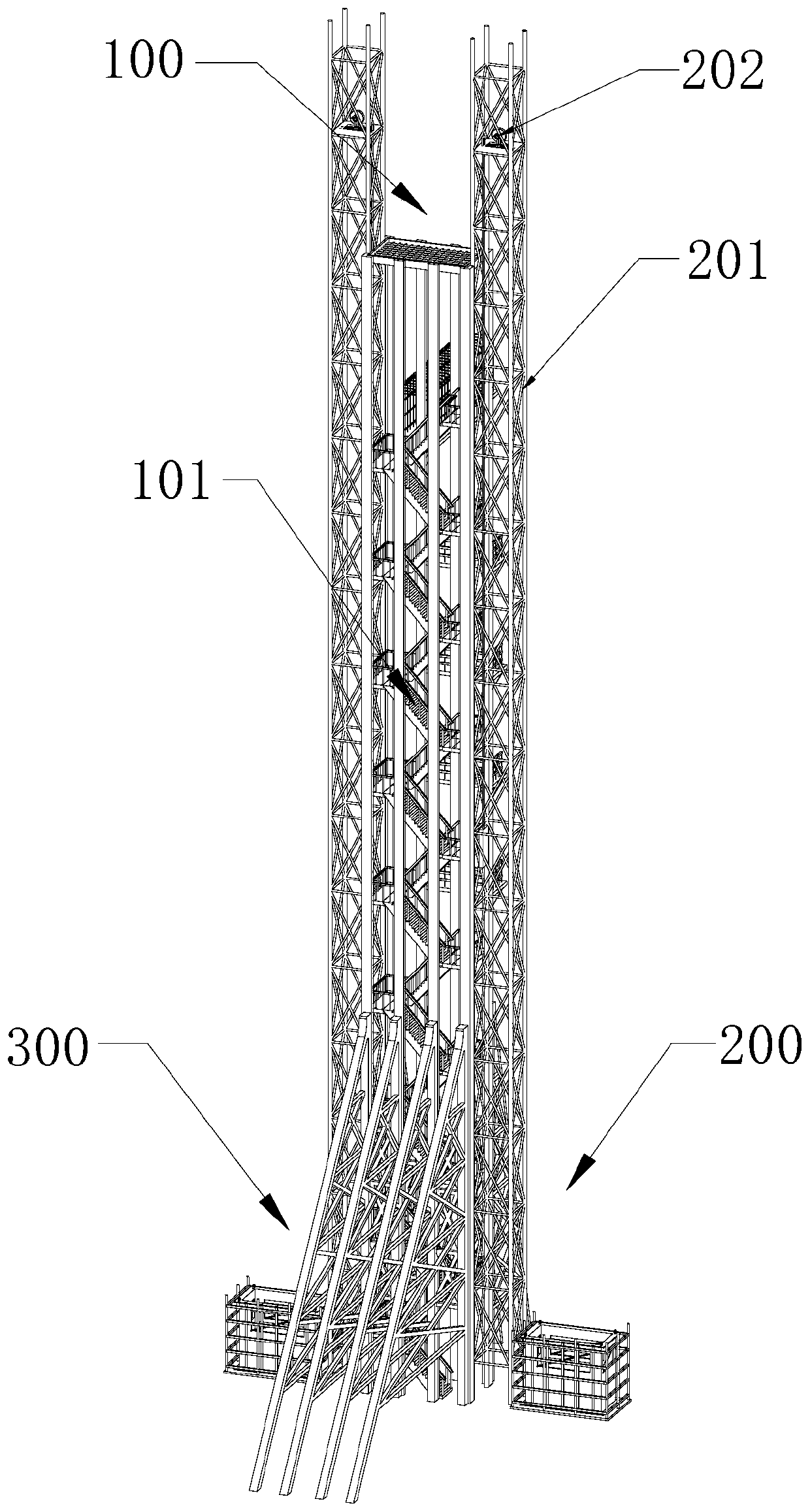

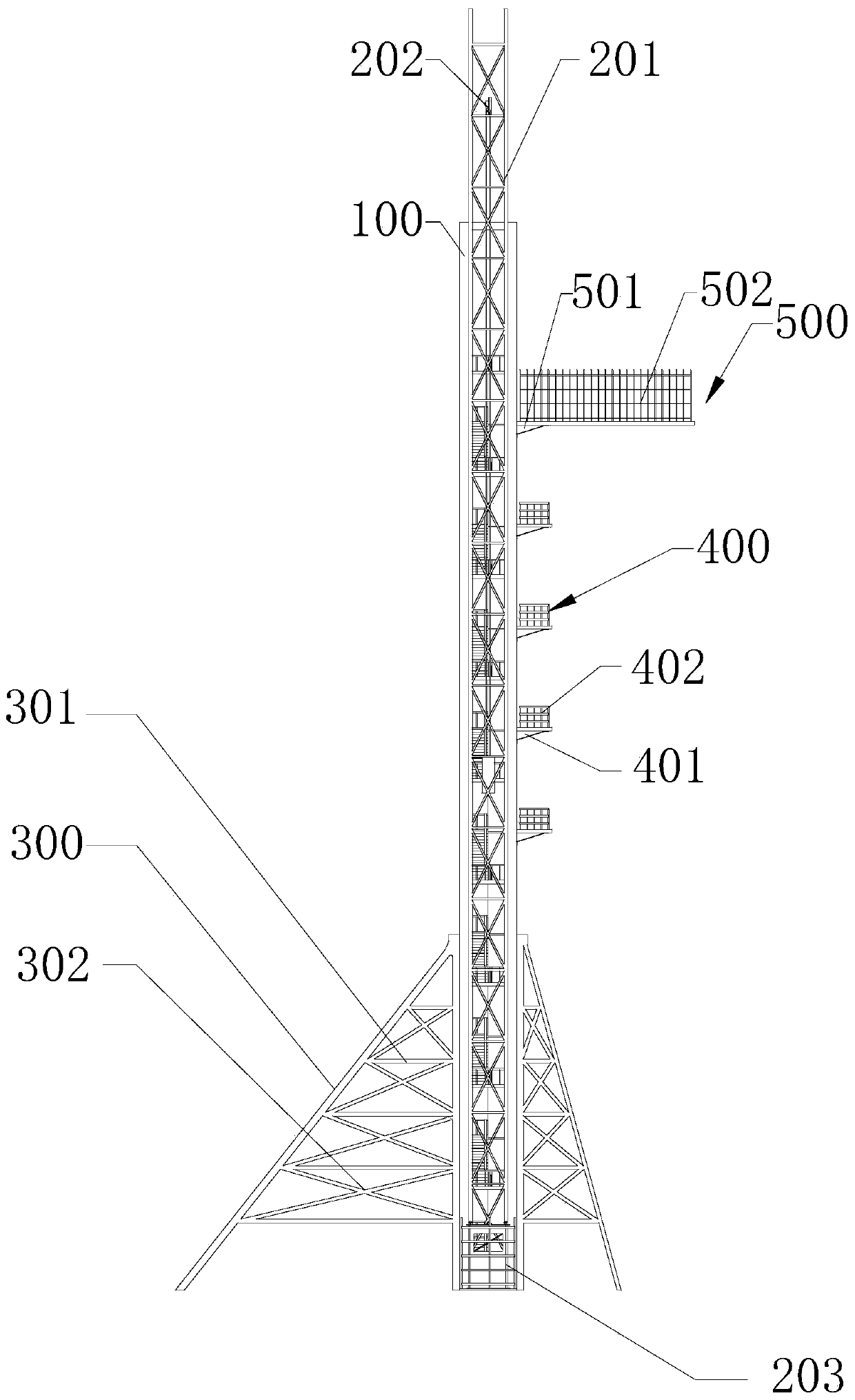

[0025] see Figure 1~3 , an embodiment of the boarding tower of the cruise ship construction tooling of the present invention is shown in the figure, which includes:

[0026] A boarding tower main structure 100, boarding ladder 101 is installed inside it, this boarding tower main structure 100 and boarding ladder 101 are detachable structures, in the present embodiment, the width of boarding ladder 101 satisfies four to five people At the same time, handrails 102 are provided on both sides of the passage of the boarding ladder 101;

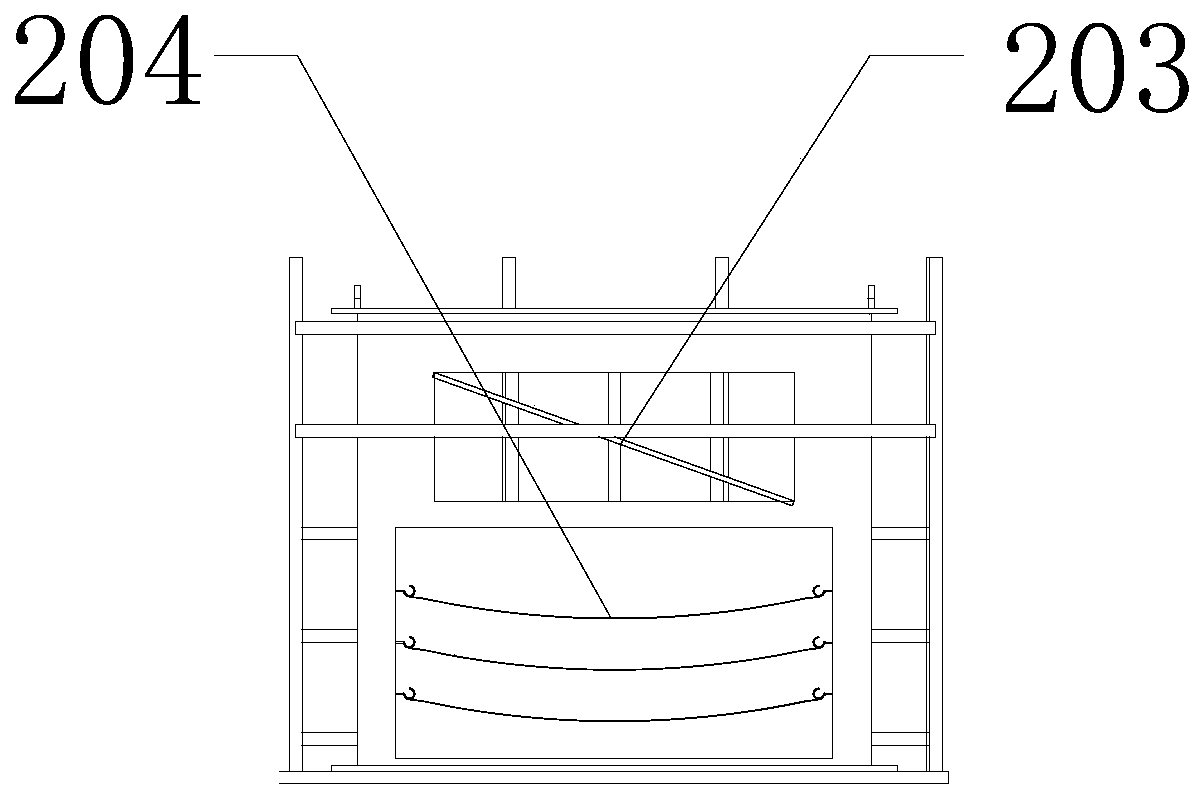

[0027] The left and right sides of the boarding tower main structure 100 are equipped with transport elevators 200, and each transport elevator 200 includes: an elevator shaft 201, one side of which is detachably connected with the boarding tower main structure 100, and a traction mechanism 202 is installed on the top , an elevator car 203 is installed on the other side, and the elevator car 203 is pulled by the traction mechanism 202; in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com