Sealing structure and liquid storage container

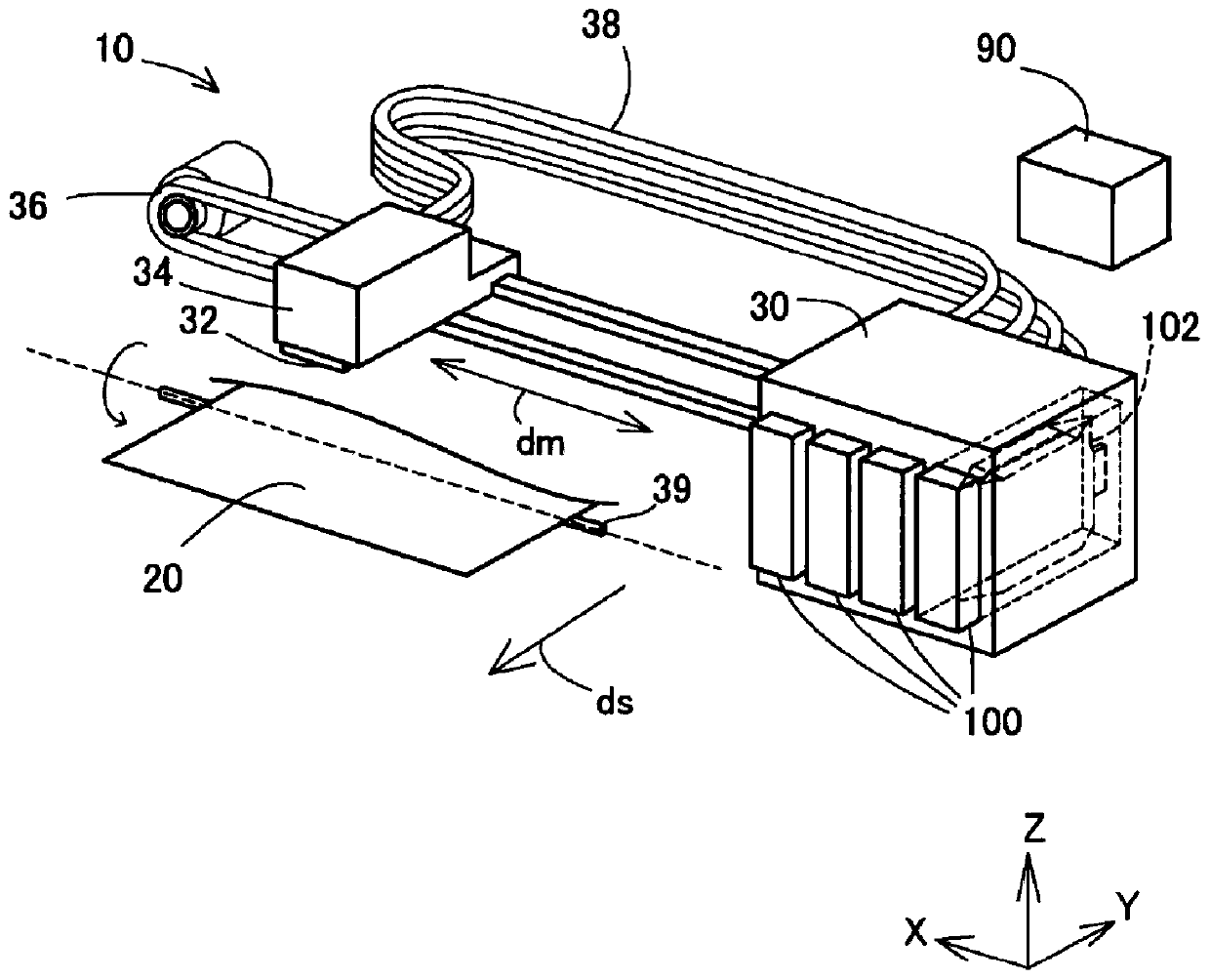

A technology for a liquid accommodating container and a sealing structure, which is applied in the directions of printing and printing devices, etc., can solve the problems of the deterioration of the sealing performance of the flow path and the deformation of the sealing parts in the sealing structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 2

[0053] Although the liquid storage container 100 of the above-mentioned embodiment has been described as an inkjet printer and a container for supplying ink to the inkjet printer, it is not limited thereto, and can also be applied to ejection of various liquids containing ink. Any liquid ejection device, and a liquid tank for containing its liquid.

[0054] The content derived from the embodiment is described below.

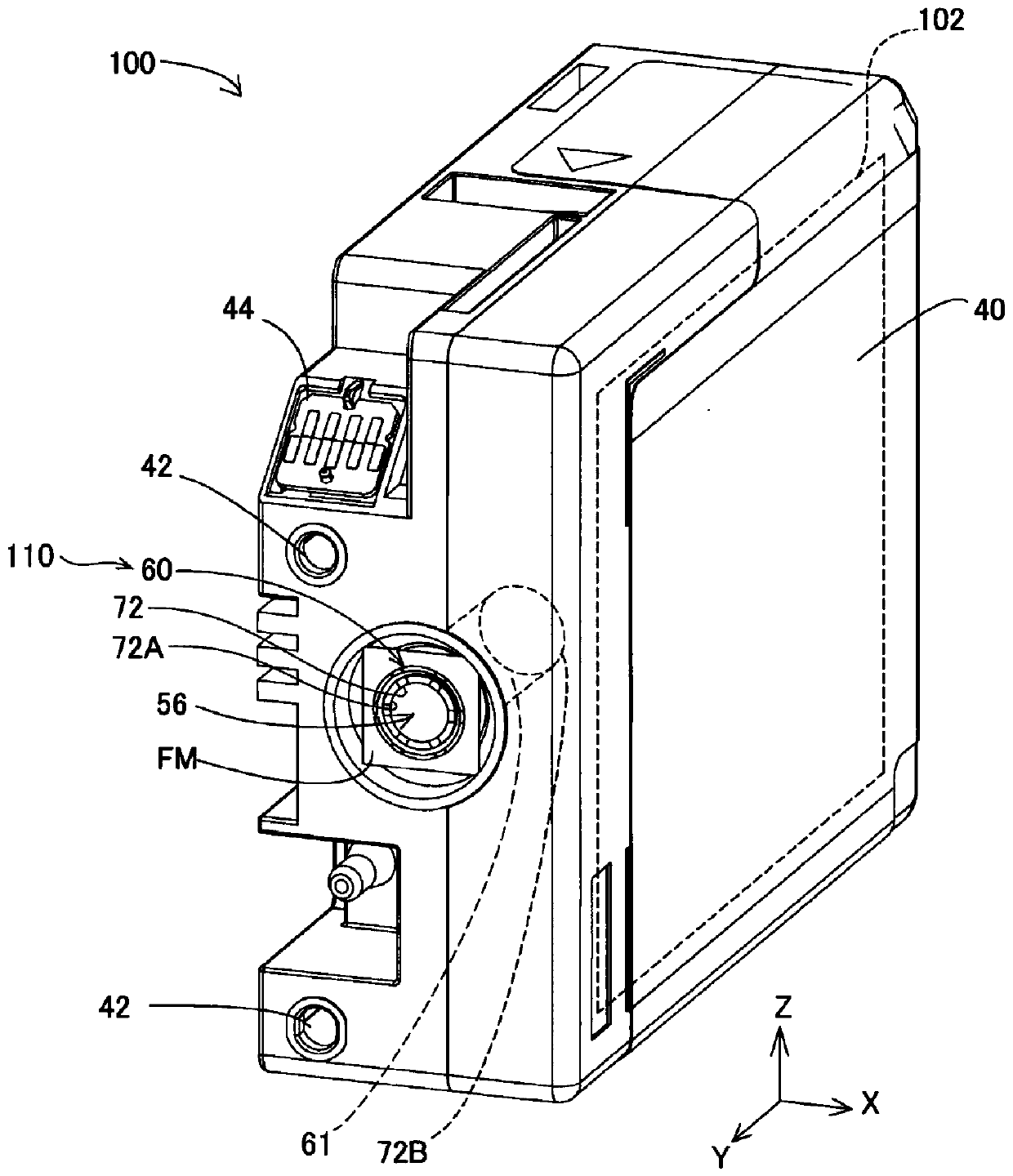

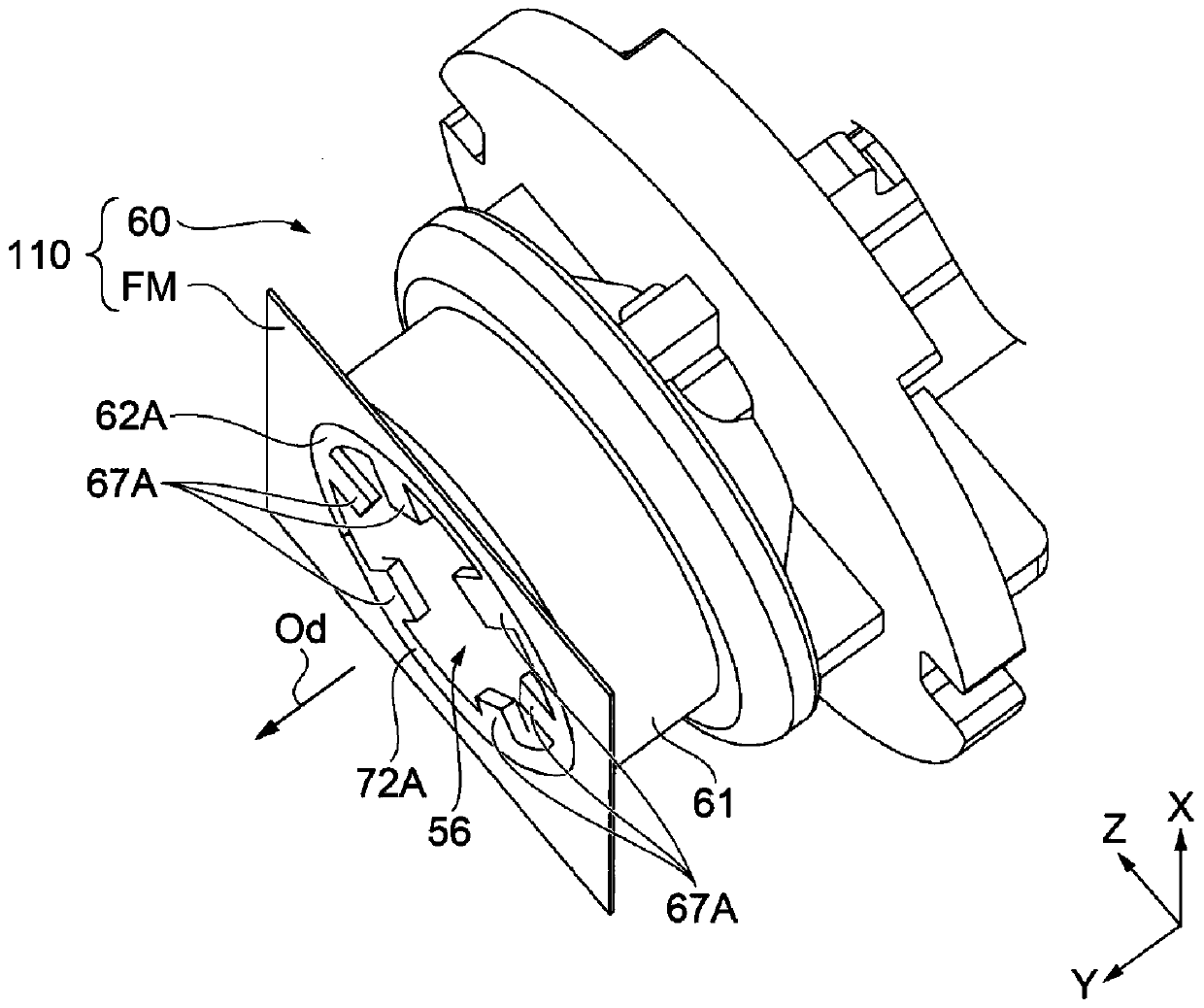

[0055]A sealed structure, which is a sealed structure of a liquid storage container, is characterized in that it includes: a liquid outlet part formed with an opening for leading out the liquid in the liquid storage container; The opening portion, the liquid outlet portion has: a flow path forming member, which forms a flow path leading to the opening portion; and a sealing member, which is arranged in the flow path, in the flow path forming member A welding protrusion protruding further from a surface of the sealing member on the side of the opening is formed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com