Disk lifting and grasping device

A grasping device and hanging plate technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of unstable grasping, troublesome debugging, and large space occupation, so as to reduce the cost of accessories, meet production needs, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

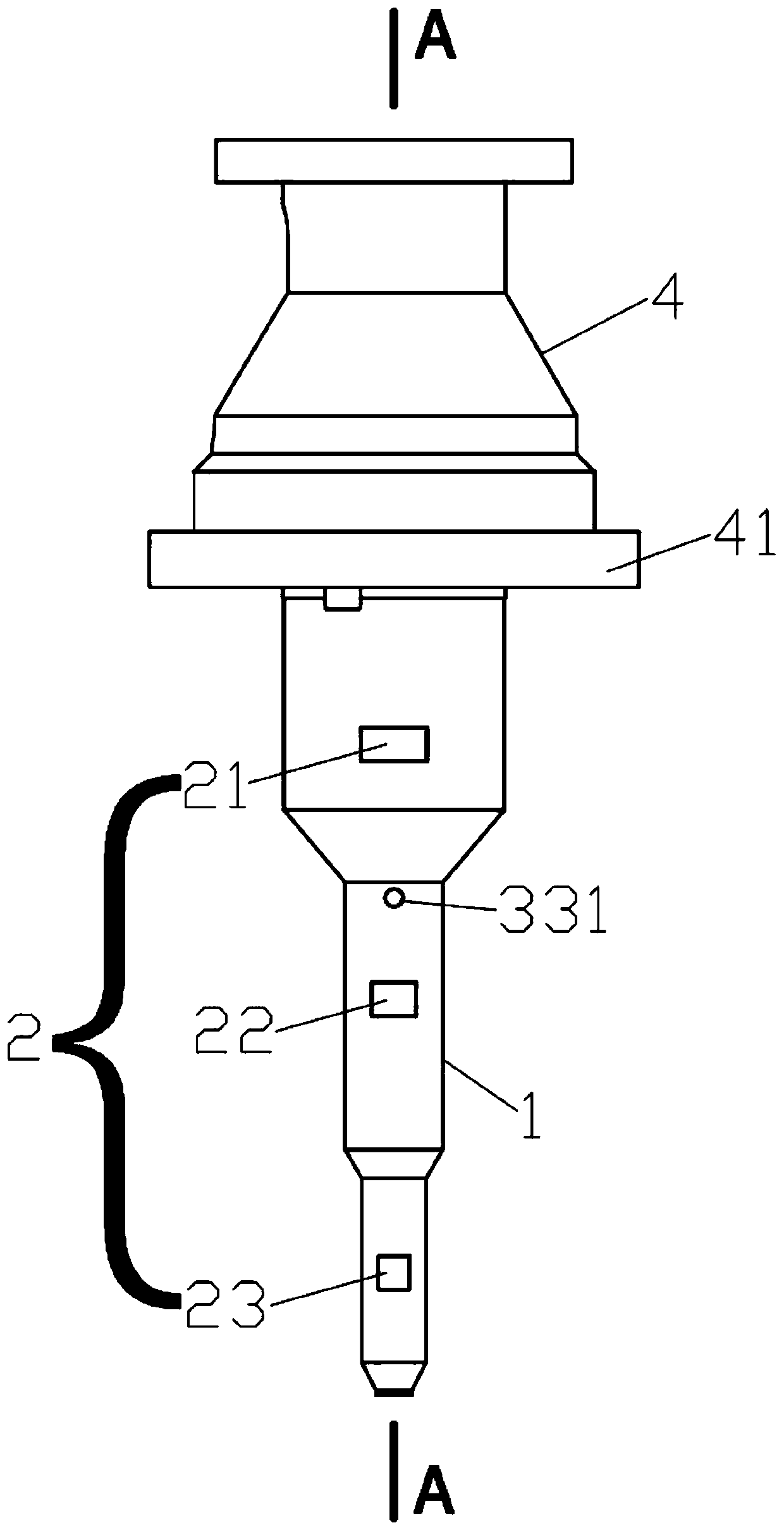

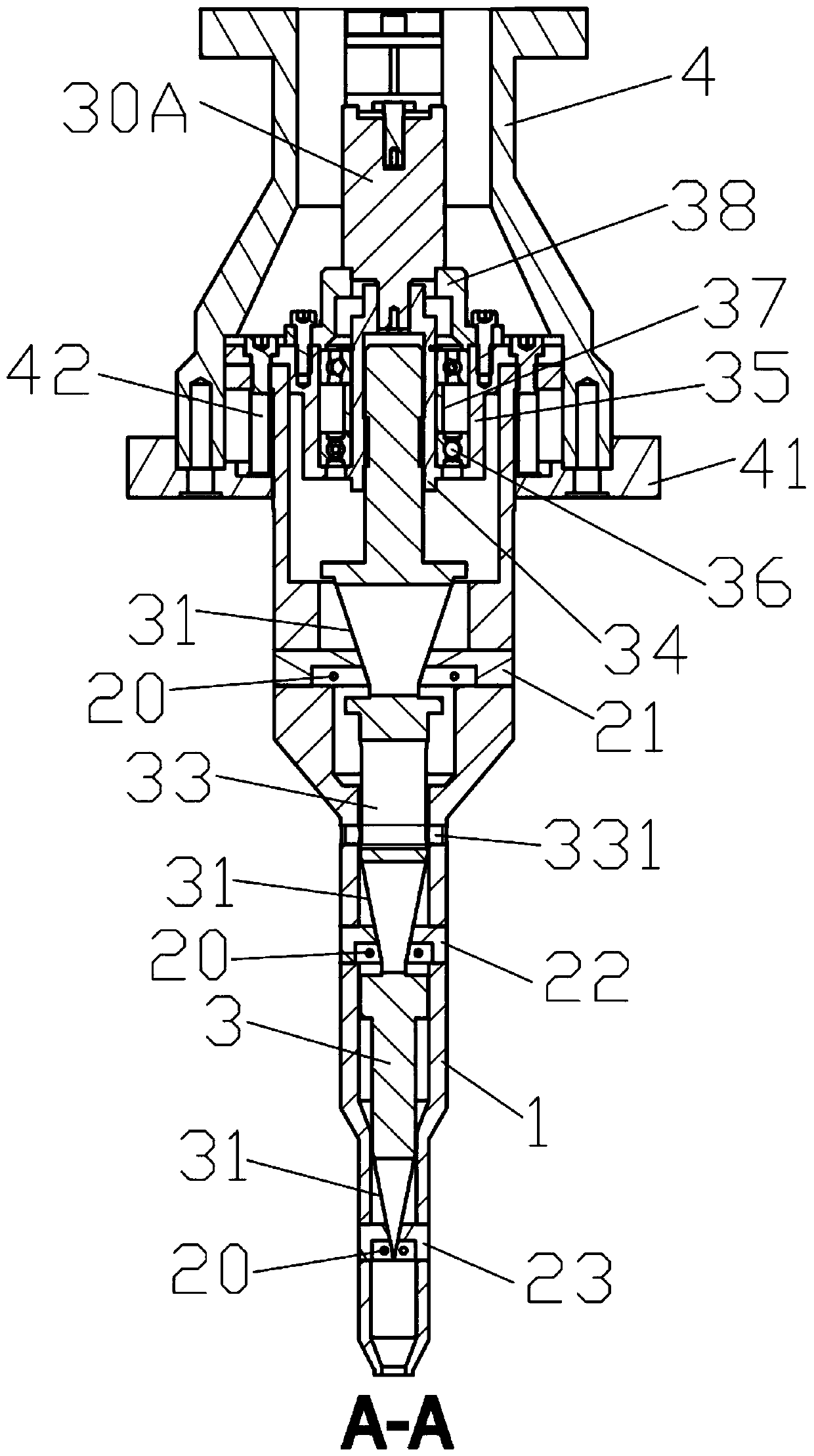

[0022] Such as figure 1 and 2 As shown, the hanging pan grabbing device according to one embodiment of the present invention includes a hanging pan shaft 1, the hanging pan shaft 1 is a hollow structure, the hanging pan shaft 1 is connected with a hinge block assembly 2, and the hinge block assembly 2 can extend or Retract on the outer wall of the suspension shaft 1. When the pan needs to be hoisted, the pan shaft 1 is inserted into the center hole of the pan from above, and the hinge block assembly 2 protrudes from the outer wall of the pan shaft 1, and hooks the lower surface of the top surface of the pan from the center hole of the pan , the structure of the lifting pan grabbing device is compact, the pan is hoisted from the inside, and the occupied space is small, and in the process of transfer, the hoisting of the pan from the inside is more stable than the grabbing of the pan from the outside.

[0023] Such as image 3 As shown, in order to control the telescopic or r...

Embodiment 2

[0029] Such as Figure 5 As shown, the main difference between Embodiment 2 and Embodiment 1 is that the control shaft driving member 30 that drives the control shaft 3 is different. In this embodiment, pneumatic control is mainly used.

[0030] Such as Figures 5 to 7 As shown, the control shaft driving part 30 is a cylinder 30B, the top of the suspension plate shaft 1 is installed with an end cover assembly 1 51 through bolts, and the end cover assembly 1 51 is installed with an end cover assembly 2 52 through bolts, and the cylinder body of the cylinder 30B is fixedly installed In the end cover assembly 2 52 , the piston rod of the cylinder 30B passes through the end cover assembly 1 51 and connects to the top of the control shaft 3 . The cylinder body of the air cylinder 30B is housed in the fixed sleeve 4 , the lower cover plate 41 is installed by bolts at the lower end of the fixed sleeve 4 , and a guide post 42 is arranged between the lower cover plate 41 and the susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com