rotors for motors

A technology of rotors and rotor laminations, applied in the field of rotors, can solve problems such as large installation space, and achieve the effects of space-saving structure, improved service life, and improved operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

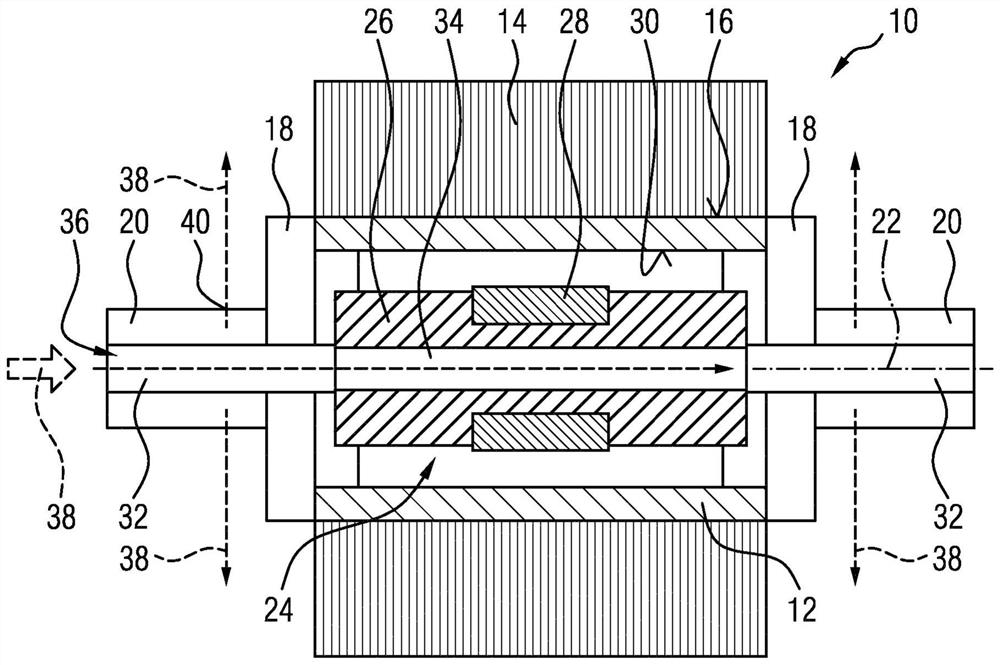

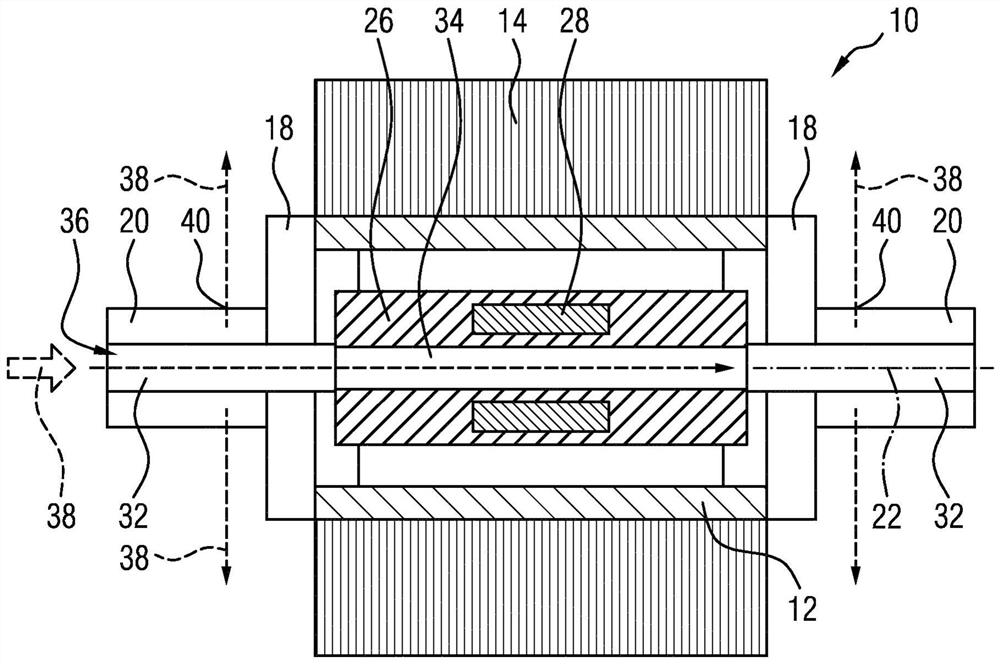

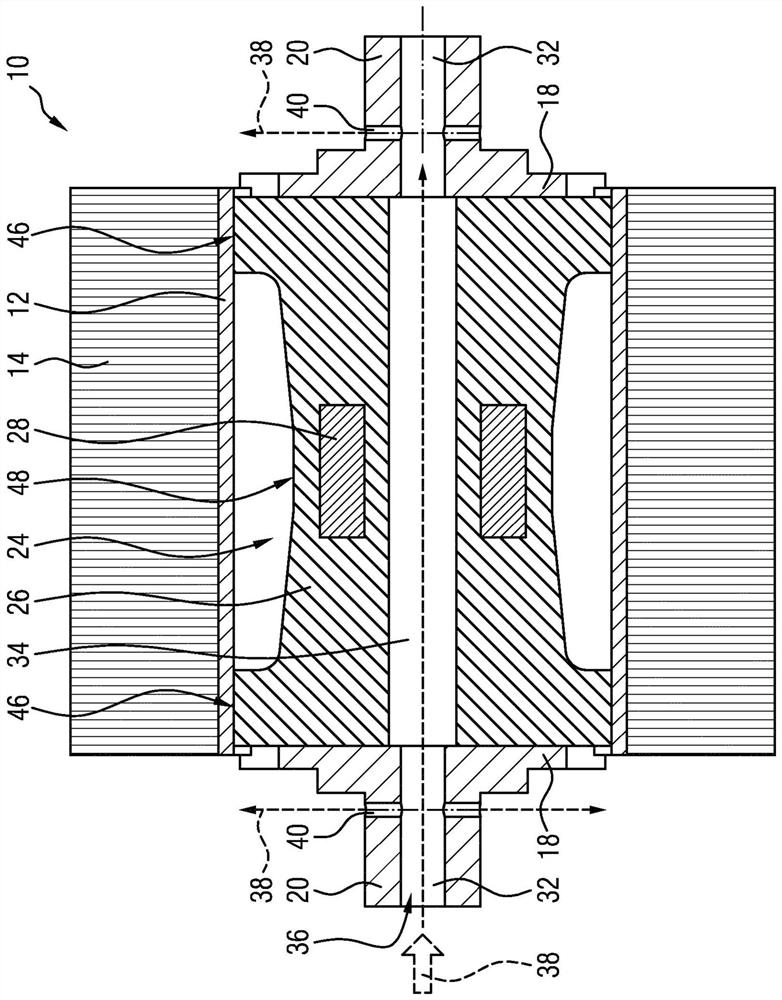

[0027] figure 1 The rotor 10 for the electric machine 11 is shown. The rotor 10 has a hollow-cylindrical laminated core carrier 12 . The laminated core carrier 12 can be, for example, a hollow rotor shaft. The laminated core support 12 preferably has an inner diameter of >30 mm. The rotor lamination core 14 is arranged on the lamination core support 12 . Preferably, the rotor lamination core 14 is rotationally fixedly attached to the lamination core support 12 . This means that the rotor lamination core 14 is at least partially supported on the peripheral surface 16 of the lamination core carrier 12 and / or is preferably connected to this peripheral surface by a friction fit and / or by a material bond. Thus, rotational movement and / or torque of the rotor lamination core 14 may be transmitted to the lamination core support 12 .

[0028] An end flange 18 is arranged at each axial end of the laminated core support 12 , wherein each end flange 18 has a journal 20 formed coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com