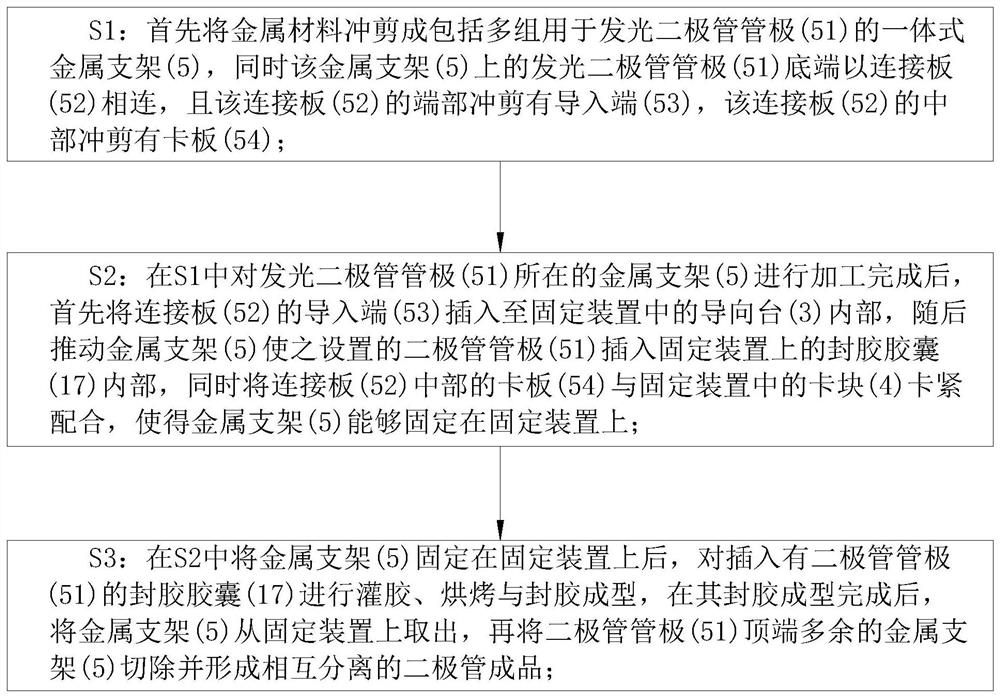

A light-emitting diode non-guide pillar sealing molding process

A light-emitting diode and molding process technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as poor fixing effect, low fixing efficiency of fixing structure, and inability to adjust and adapt light-emitting diode tubes, so as to improve the fixing effect and improve The effect of production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

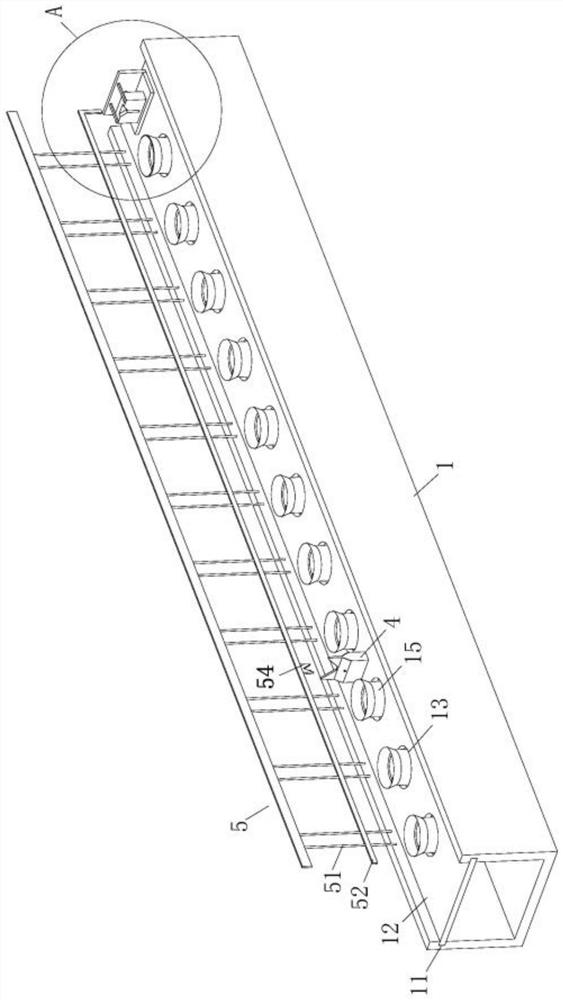

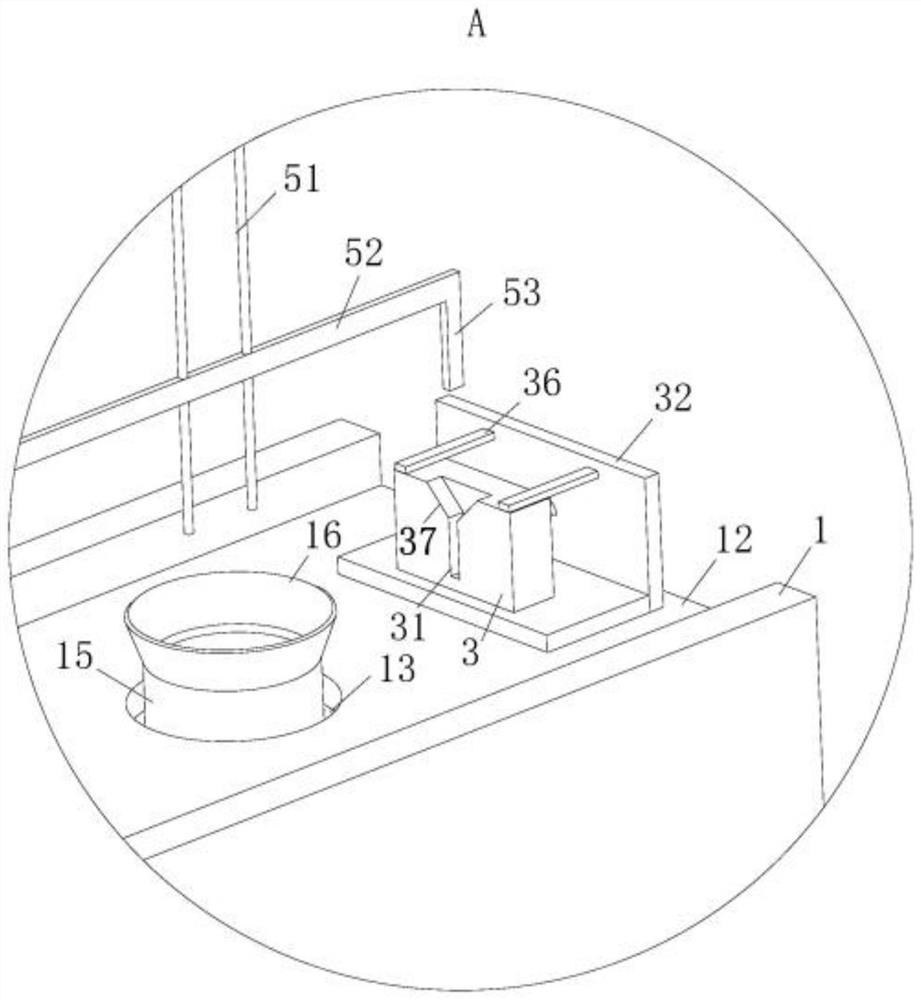

[0034] As an embodiment of the present invention, a guide frame 32 is provided between the guide table 3 and the support plate 12, a chute 33 is provided on the bottom surface of the guide frame 32, and a bottom end of the guide table 3 is provided with The slide block 34 that can slide freely inside the chute 33, the No. 2 spring 35 is connected between the side wall of the guide table 3 and the guide frame 32; The clamping plate 54 on the metal bracket 5 that produces errors in size is easily misplaced with the matching clamping block 4, thereby affecting the matching effect between the clamping plate 54 and the clamping block 4. At this time, by setting the guide table 3 so that it can be placed on the guide frame 32 In the form of activity, when the metal bracket 5 is eccentric, the lead-in end 53 exerts force on the guide table 3 at this time, so that the guide table 3 stretches the second spring 35 and drives the slider 34 to slide inside the chute 33 , so that the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com