Method for disassembling main shaft of vertical hydro-generator

A technology for hydroelectric generators and generators, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., which can solve the problems of difficult penetration of coupling bolts, difficult installation, and high risks, so as to shorten the maintenance period and reduce The risk of collision, the effect of reducing construction difficulty and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

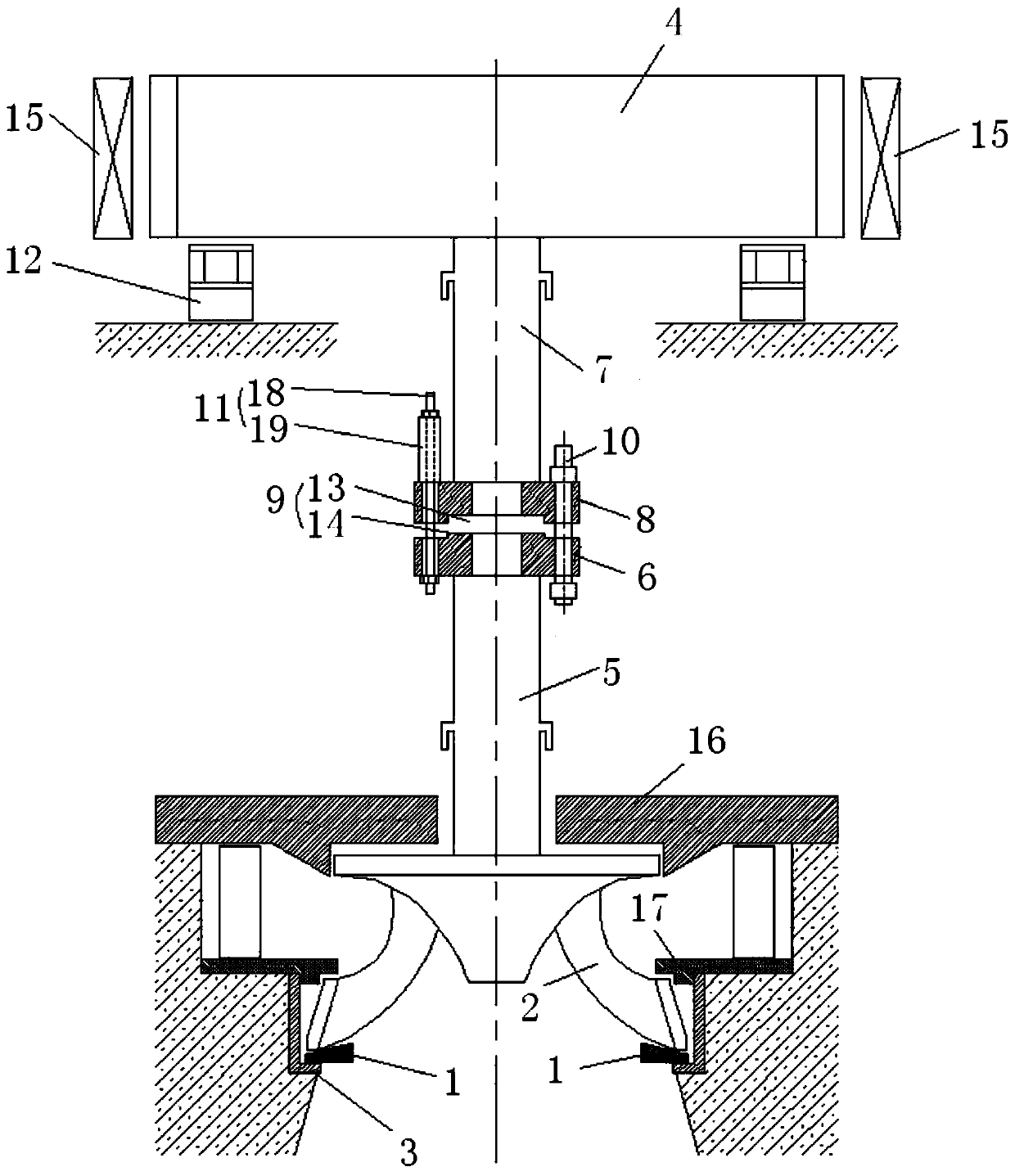

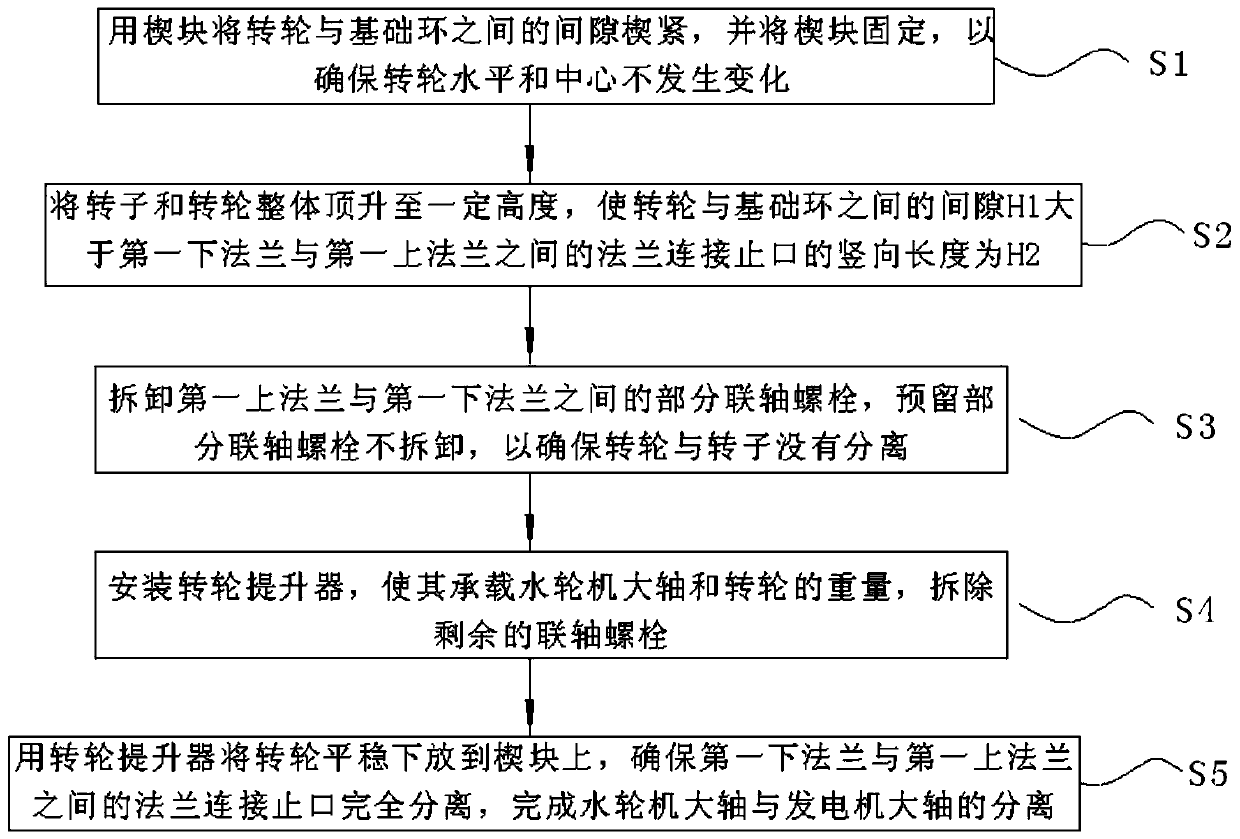

[0034] Such as figure 1 and figure 2 As shown, the large shaft dismounting method of the vertical hydroelectric generator of the present embodiment includes the following steps:

[0035] S1. Use the wedge 1 to wedge the gap between the runner 2 and the base ring 3, and fix the wedge 1 to ensure that the level and center of the runner 2 do not change;

[0036] S2. Use the rotor jacking device to lift the rotor 4 and the runner 2 to a certain height. At this time, the gap between the runner 2 and the base ring 3 is H1. There is a flange connection spigot 9 between the first upper flange 8 of the main shaft 7, and the vertical length of the flange connection 9 is H2, which satisfies H1>H2 (not shown in the figure of H1 and H2), that is The gap between the runner 2 and the base ring 3 is greater than the separation gap of the flange joint 9;

[0037] S3. Disassemble part of the coupling bolts 10 between the first upper flange 8 and the first lower flange 6, and reserve part of...

Embodiment 2

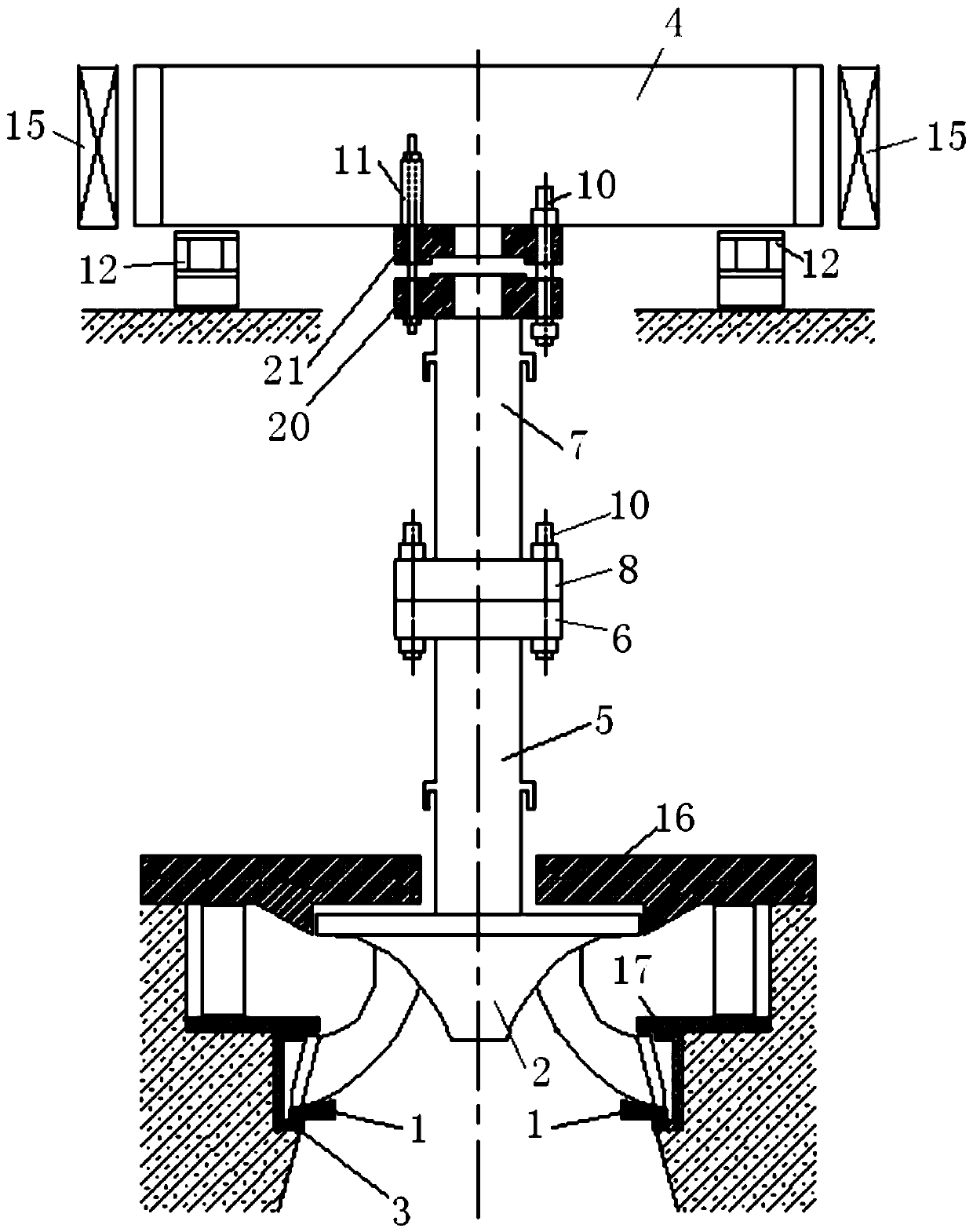

[0048] Such as image 3 As shown, the dismantling method of the large shaft of the vertical hydroelectric generator of this embodiment is the same principle as that of the embodiment 1, the only difference is that the embodiment 1 is aimed at the difference between the large shaft 7 of the generator and the large shaft 5 of the water turbine. The first upper flange 8 and the first lower flange 6 between the rotor 4 and the first lower flange 6 are disassembled. In this embodiment, the second upper flange 21 and the second lower flange 20 between the rotor 4 and the generator shaft 7 are disassembled. Specific steps are as follows:

[0049] S1. Use the wedge 1 to wedge the gap between the runner 2 and the base ring 3, and fix the wedge 1 to ensure that the level and center of the runner 2 do not change;

[0050] S2. Use the rotor lifting device to lift the rotor 4 and the runner 2 to a certain height. At this time, the gap between the runner 2 and the base ring 3 is H1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com