Electroplating process and device based on field of metal surface treatment

An electroplating process and electroplating equipment technology, applied in the direction of electrodes, plating tanks, electrolytic processes, etc., can solve the problems of affecting the quality of electroplating, uneven thickness of the coating, etc., and achieve the effect of improving practicability, improving the quality of electroplating, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

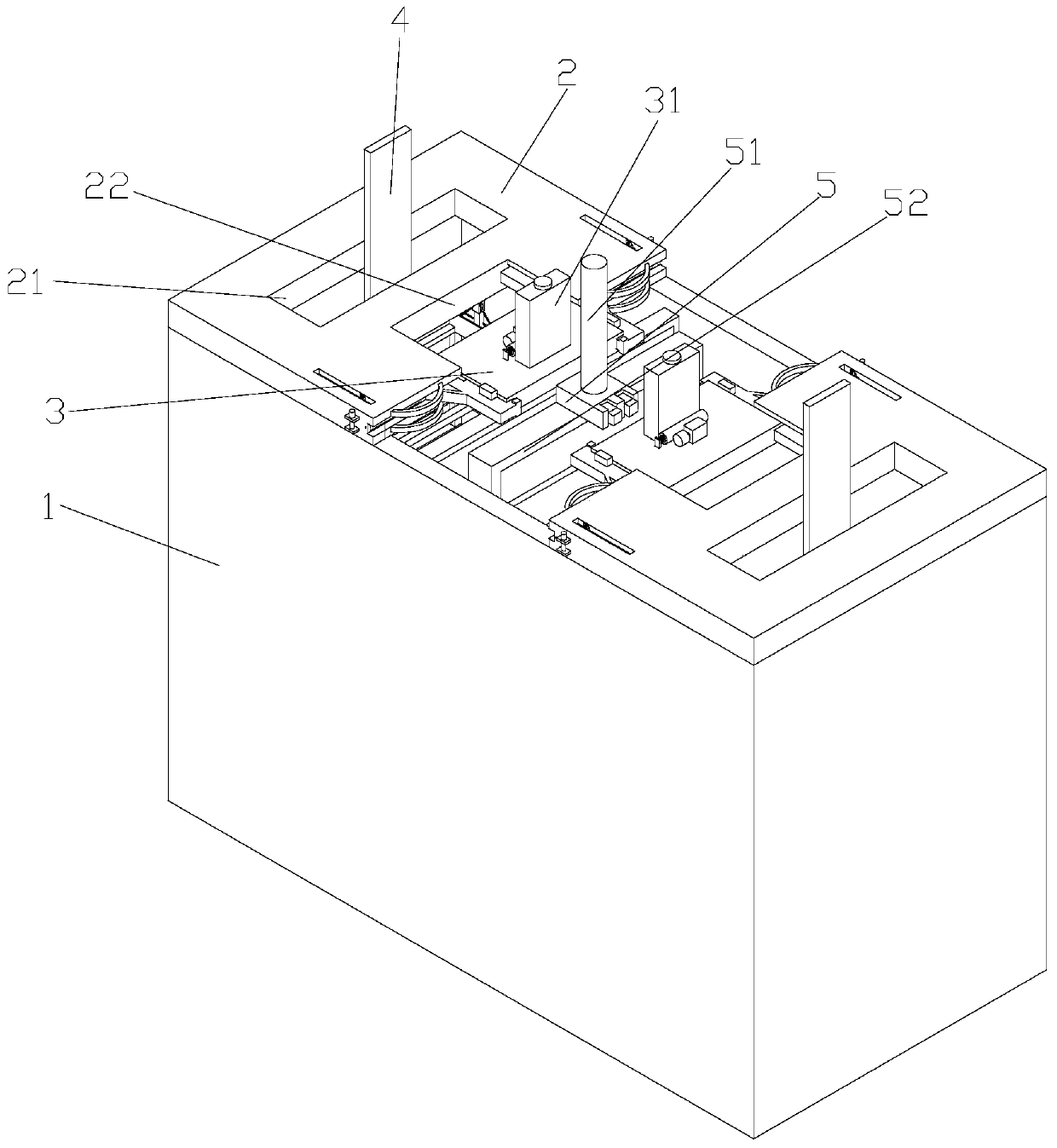

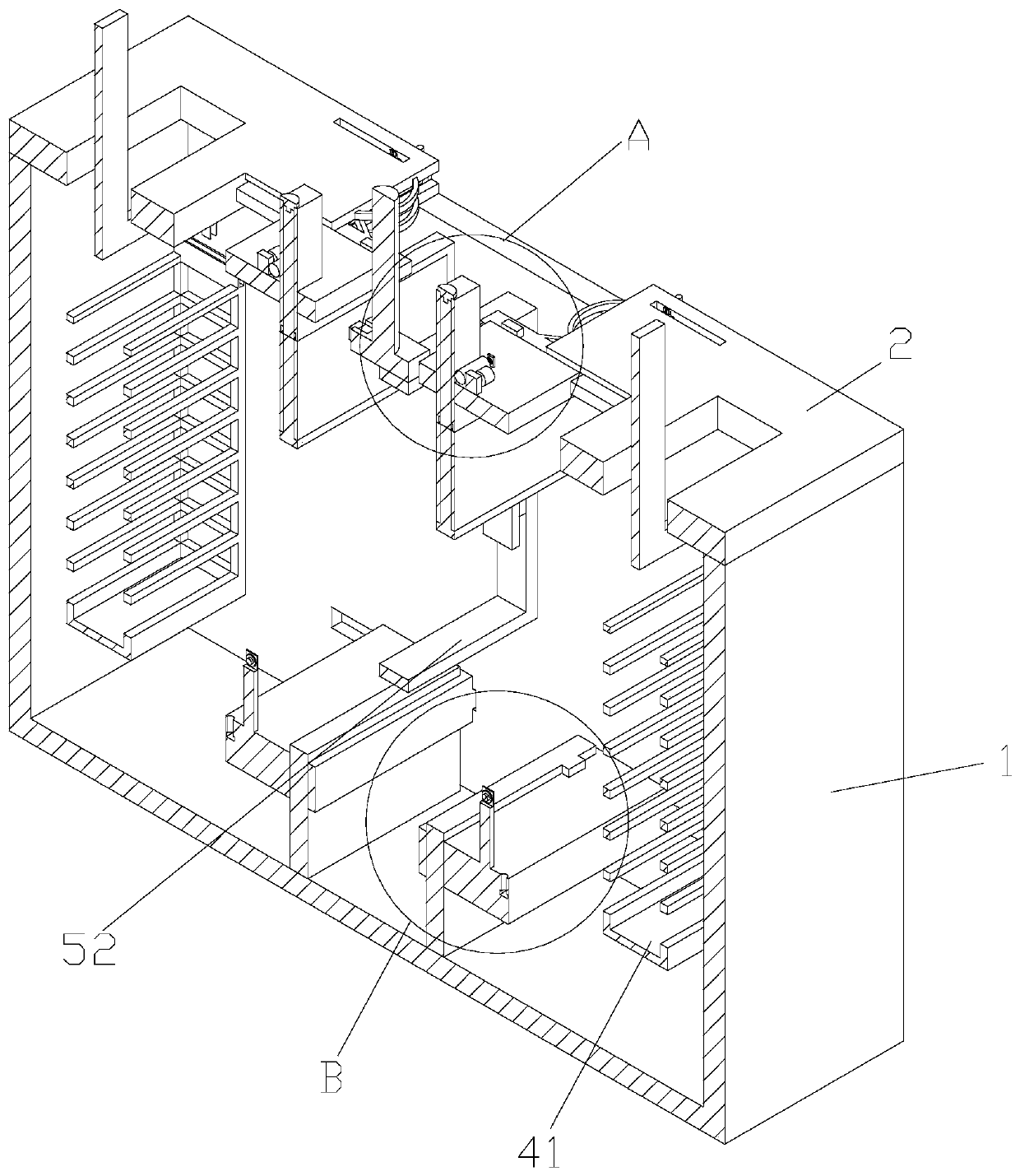

[0042]An electroplating process based on the field of metal surface treatment, comprising: putting a pair of anodes and a plated piece into an electroplating device filled with an electroplating solution, the pair of anodes are respectively arranged on the left and right sides of the plated piece and are respectively connected to the The positive pole of the power supply is electrically connected, and the plated piece is electrically connected with the negative pole of the power supply as a cathode; a pair of first baffle plates that can be moved up and down are arranged between the pair of anodes and close to the plated piece. At one end, a pair of second baffle plates that can be moved up and down are arranged between the pair of anodes and close to the other end of the plated piece; when the plated piece needs to be partially electroplated, the upper baffle plate moves downward, and the lower baffle plate The plate moves upwards so that the area of the plated piece to be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com