Glue dispensing method and system

A technology of dispensing and dispensing head, which is applied in the direction of material gluing, connecting components, and devices for coating liquid on the surface, etc. It can solve the problems of time-consuming and affecting the production efficiency of the whole line, so as to improve production efficiency and make the operation simple and intelligent. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

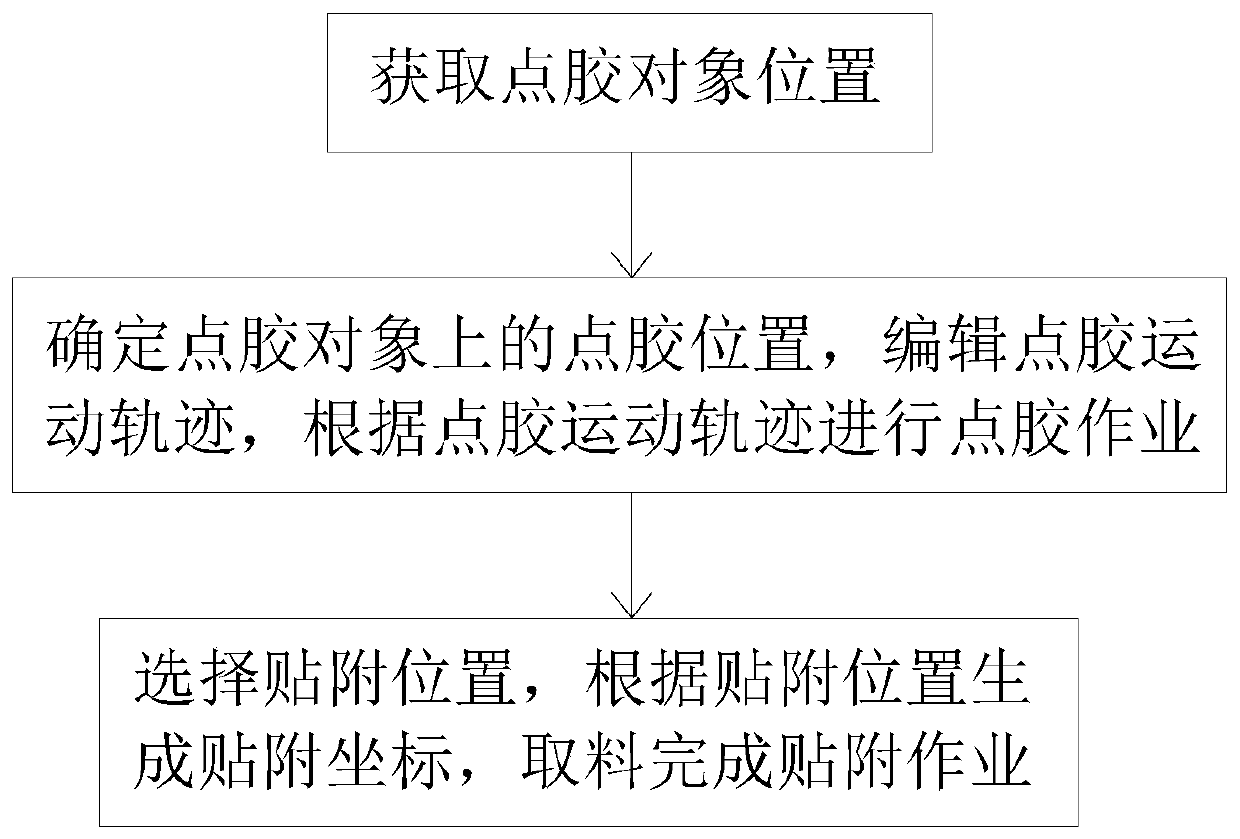

[0036] see figure 1 , the present embodiment provides a kind of dispensing method, and this method comprises the following steps:

[0037] The first step is to obtain the position of the dispensing object.

[0038] The dispensing object will be loaded through the feeding device, and the position of the dispensing object will be determined through the placement camera. When the position of the dispensing object fails to be obtained, the operation will be suspended and an alarm will be issued.

[0039] The second step is to determine the dispensing position on the dispensing object, edit the dispensing trajectory, and perform dispensing operations according to the dispensing trajectory.

[0040] Among them, the glue dispensing position can be selected manually or intelligently, and the way of editing the glue dispensing trajectory includes manual editing or visual positioning editing.

[0041] The dispensing operation can be a single dispensing of a single dispensing head or s...

Embodiment 2

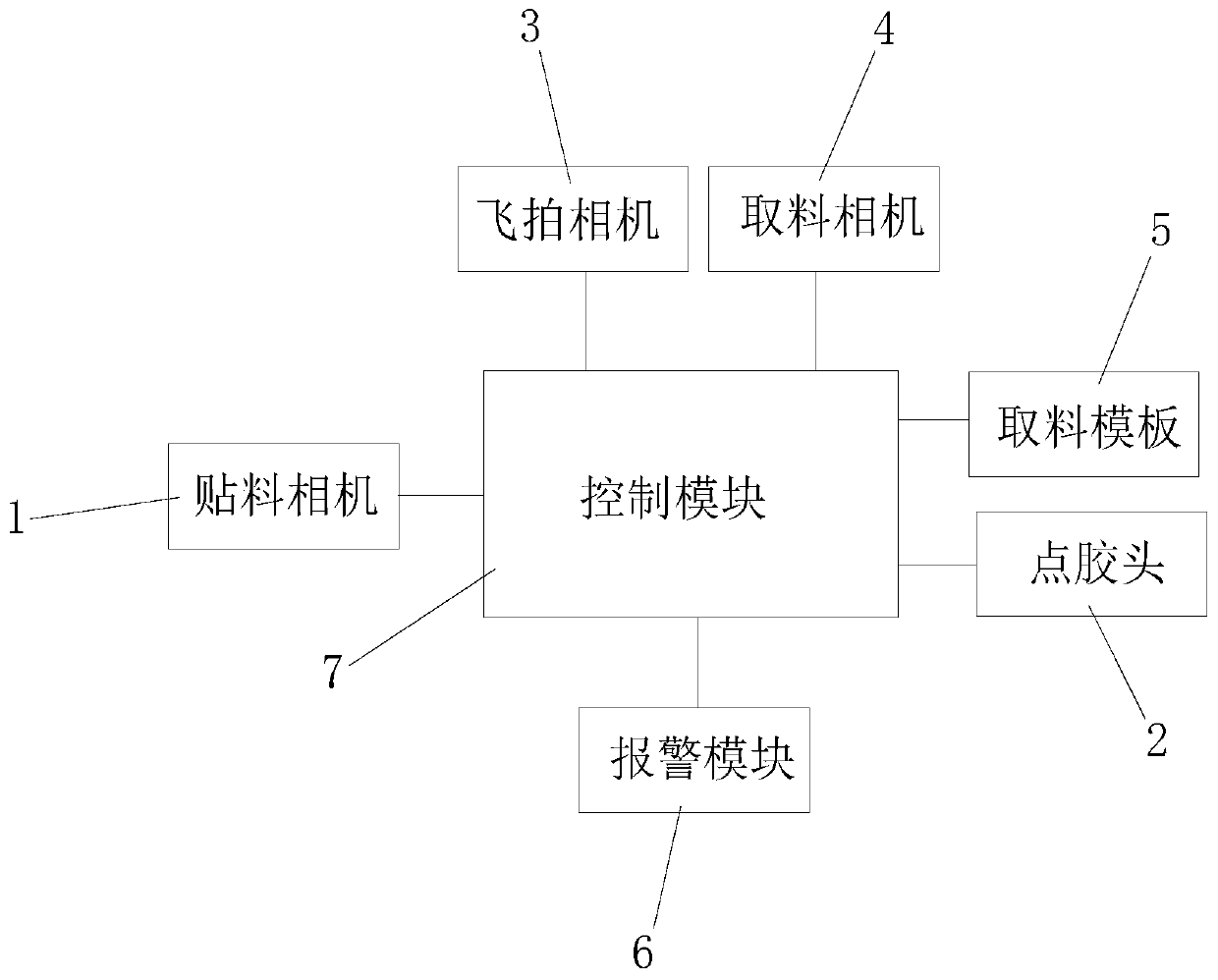

[0045] see figure 2 , the present embodiment provides a dispensing system, the system includes: a material dispensing camera 1, used to determine the position of the dispensing object, and generate the dispensing position according to the dispensing motion track, and generate the attachment position according to the attachment point; The dispensing head 2 is used to dispens the dispensing position according to the dispensing movement track; the flying camera 3 is used to correct the attachment position to improve the accuracy; the retrieving camera 4 is used to determine the retrieving position; the retrieving module 5, Take the material and complete the attachment operation; the alarm module 6, when the alarm module 6 fails to obtain the position of the dispensing object by the adhesive camera 1, an alarm is issued; the control module 7 controls the adhesive camera 1 and the dispensing head 2 , Operation and communication of flying camera 3, reclaiming camera 4, reclaiming m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com