A kind of slime mold equipment

A strain and wood strip technology, which is applied in botany equipment and methods, horticulture, agriculture, etc., can solve the problems of reduced work efficiency, easy sore hands, uneven strains, etc., and achieve the effect of avoiding waste and avoiding sore hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

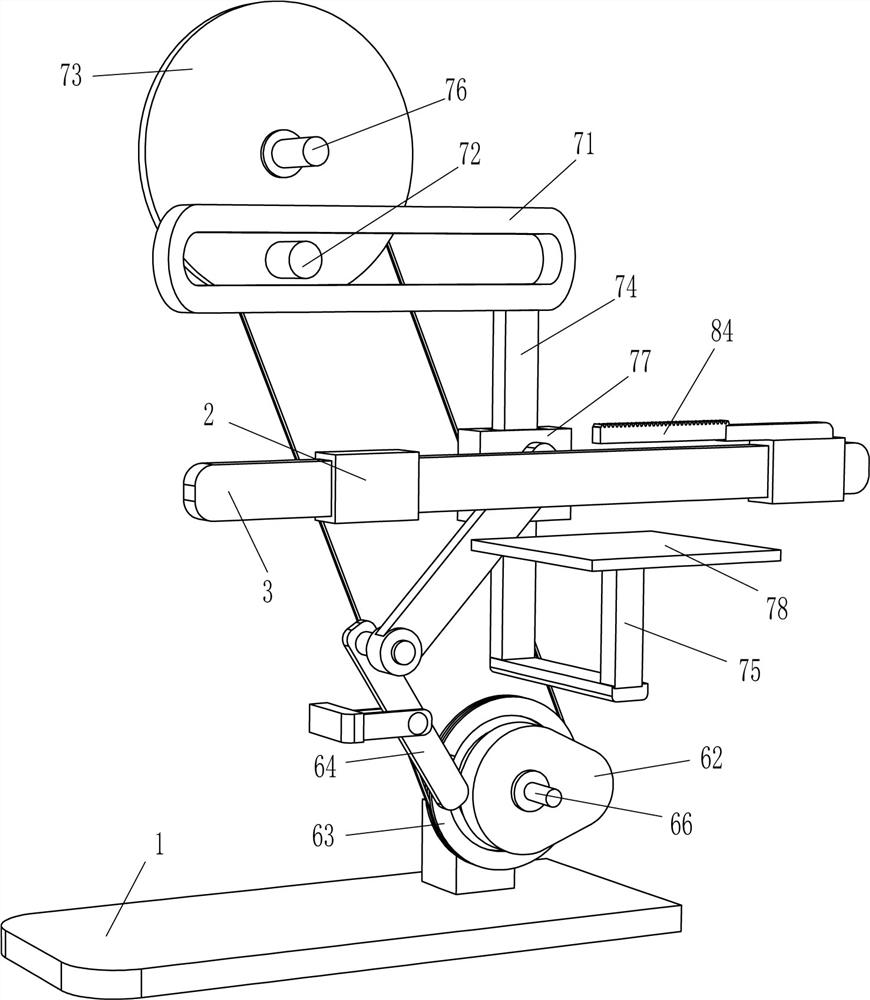

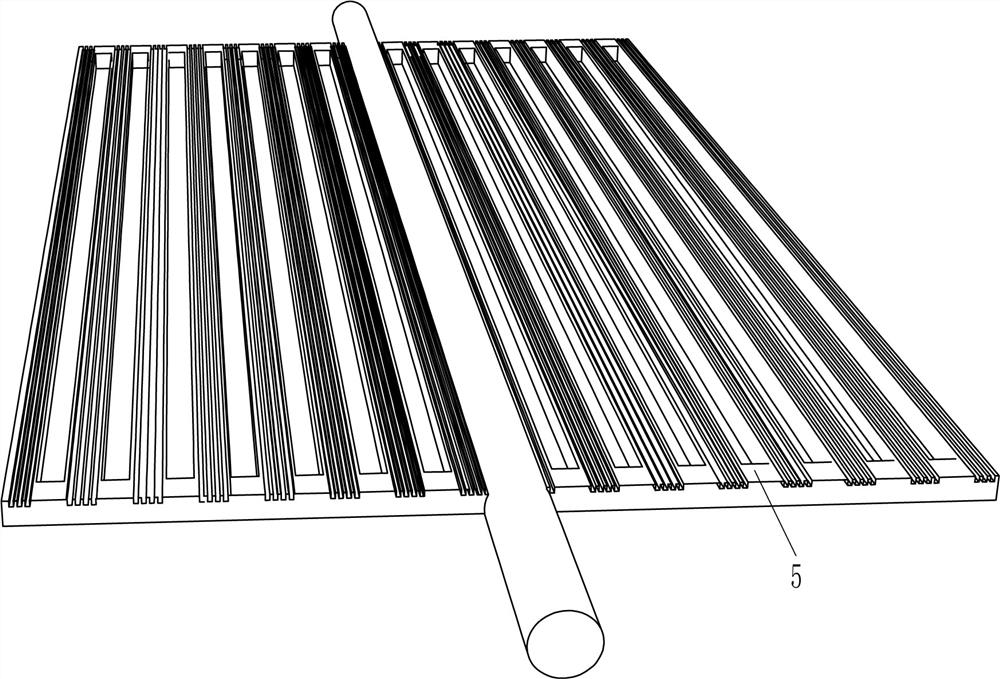

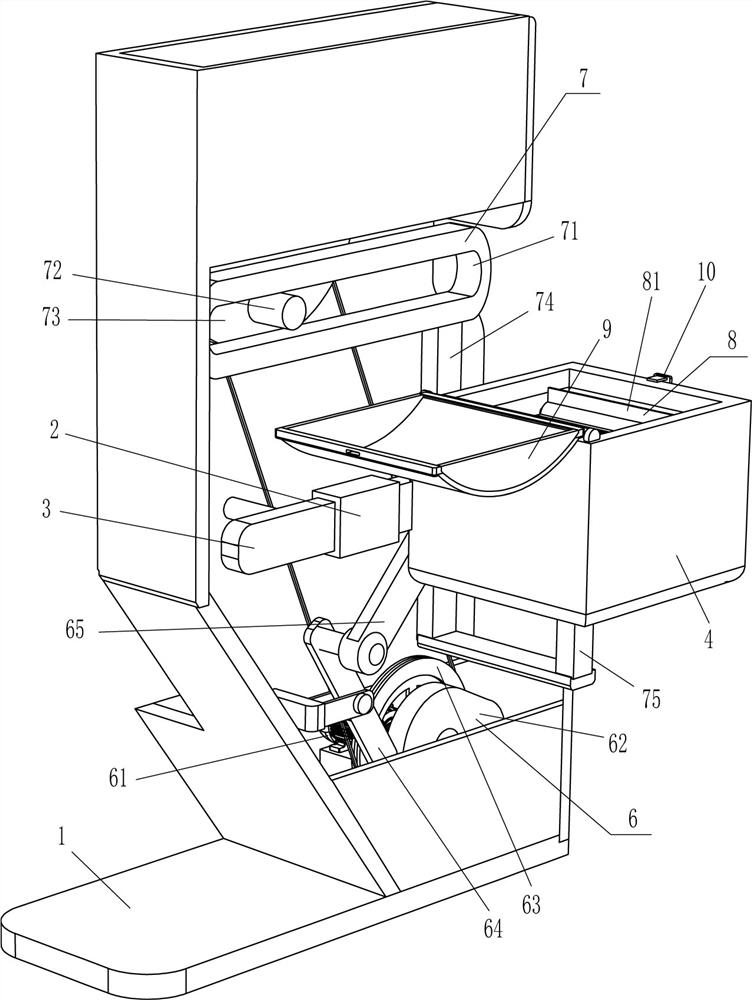

[0022] refer to Figure 1-Figure 4 , a kind of stick mold equipment, including installation shell 1, guide sleeve 2, movable plate 3, placement frame 4, placement plate 5, drive mechanism 6 and push mechanism 7, the left and right sides of the middle part of the rear side of the installation shell 1 All are fixedly connected with guide sleeves 2, and a movable plate 3 is slidably arranged between the guide sleeves 2 on the left and right sides. A placement plate 5 is fixedly connected between the left side of the upper part of the side, and the lower side of the installation shell 1 is provided with a drive mechanism 6, which is fixedly connected to the rear side of the movable plate 3, and the upper side of the installation shell 1 is provided with a drive mechanism 6. There is a pushing mechanism 7, which is connected and matched with the placement frame 4, and the pushed mechanism 7 is also connected and matched with the driving mechanism 6.

[0023] The drive mechanism 6 ...

Embodiment 2

[0029] refer to Figure 1-Figure 3 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a turning mechanism 8 is also included. Rotating between the upper side of the right part of the side is connected with a rotating rod 82, the rear end of the rotating rod 82 is fixedly connected with a gear 83, the rotating rod 82 is equipped with agitating blades 81, and the agitating blades 81 are located in the placement frame 4, and the right guide sleeve 2. A rack 84 is affixed to the top, and the rack 84 is located below the gear 83 and engages with it.

[0030] When the driving motor 61 is started, the left and right movement of the placement frame 4 also drives the gear 83 to move left and right, and the left and right movement of the gear 83 rotates alternately through the rack 84. The forward and reverse rotation of the gear 83 drives the rotating rod 82 to rotate alternately. Alternate forward and reverse rotation drives the stirring bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com