Device for controlling a stretch-reducing mill

A technology of tension reduction and rolling mill, which is applied in the direction of driving device, rolling mill control device, tail end control, etc. for metal rolling mills. It can solve the problems of not considering the influence, the influence of adjustment results, and the inability to adapt the use time and effect duration and other issues to achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

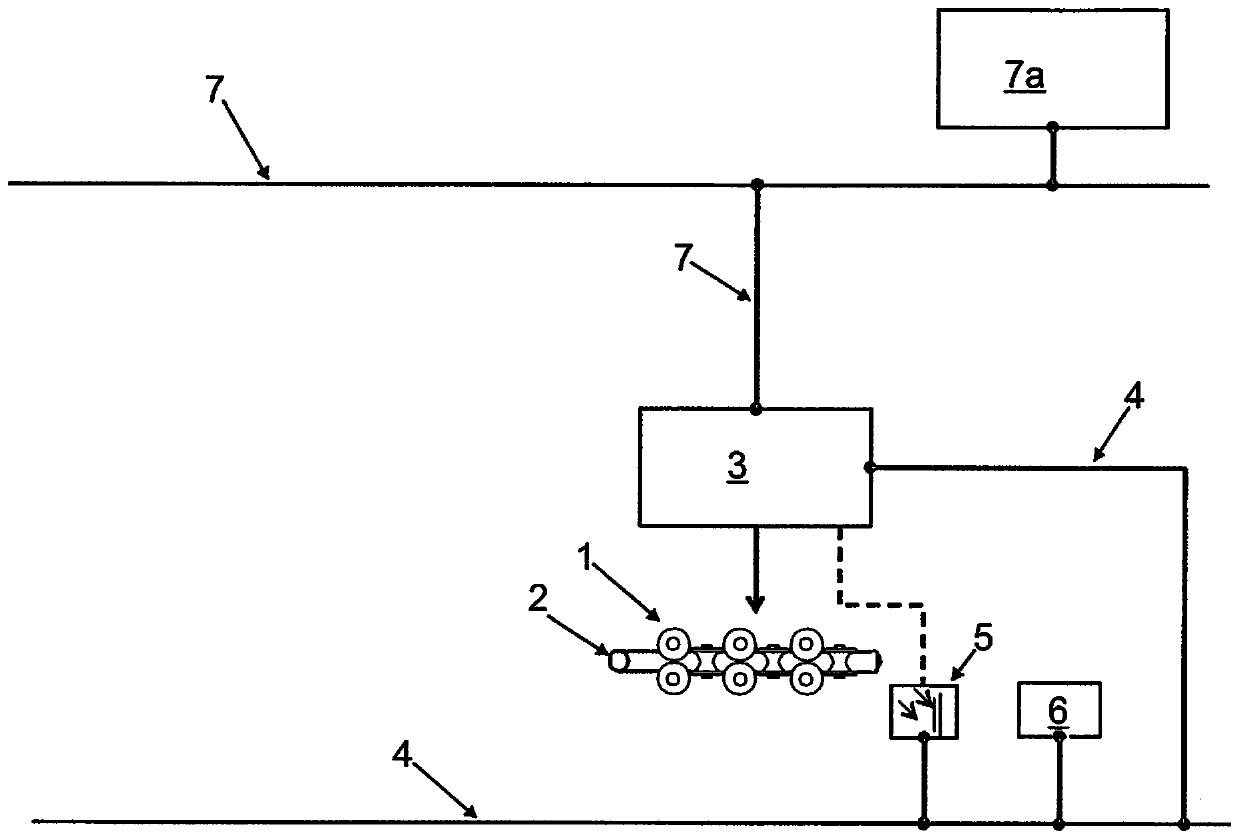

[0032] The tension reducing mill comprises a plurality of rolls in a rolling stand 1 driven by adjustable motors. In this case, the tension reduction of the rolling stock 2 takes place by targeted control of the motors with different rotational speeds, so that the rolling stock is placed under tensile stress between the rollers.

[0033] The motor is powered by a programmable controller (SPS) 3 . The SPS 3 takes over the query and / or calculation of the rotational speed of the motor during the rolling process.

[0034] The SPS 3 is connected to the sensors 5 , 6 via a network 4 in the form of a fieldbus system, so that measured values flow directly into the SPS. The sensor 5 is here by way of example a position sensor, for example in the form of a light barrier. The sensors 6 determine further measured values for monitoring the rolling process, in particular the diameter, wall thickness and temperature of the rolling stock.

[0035] Furthermore, the SPS 3 can communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com