Automatic film-changing air particulate matter sampler capable of sampling comparison sample

A technology of air particles and automatic film change, which is applied in the direction of material absorption and weighing, can solve the problems of poor sampling accuracy, unsatisfactory particle collection and automatic mold change, and poor stability, so as to improve work efficiency and automation. Collect air particulate matter comparison samples to achieve the effect of automatic collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

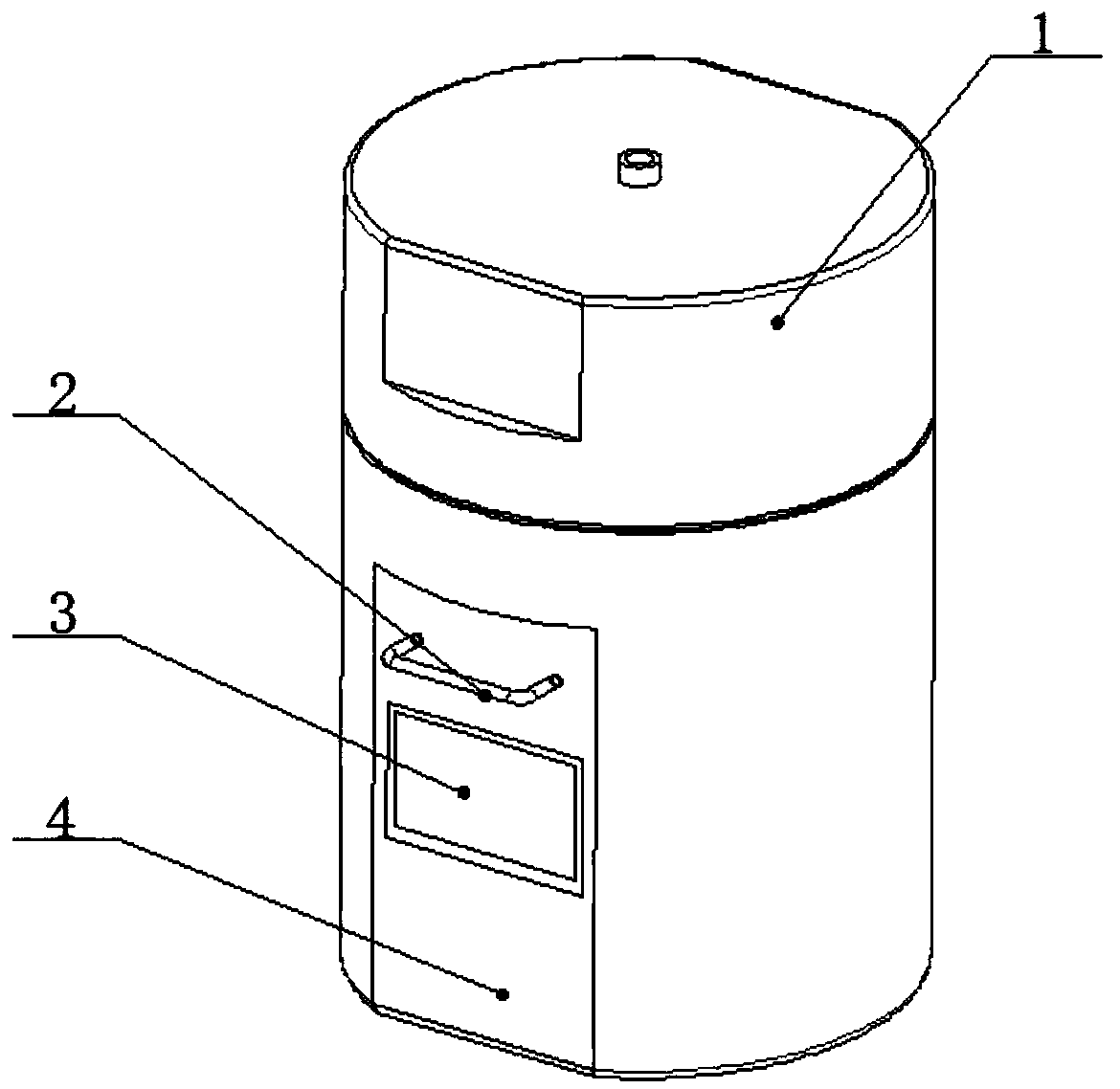

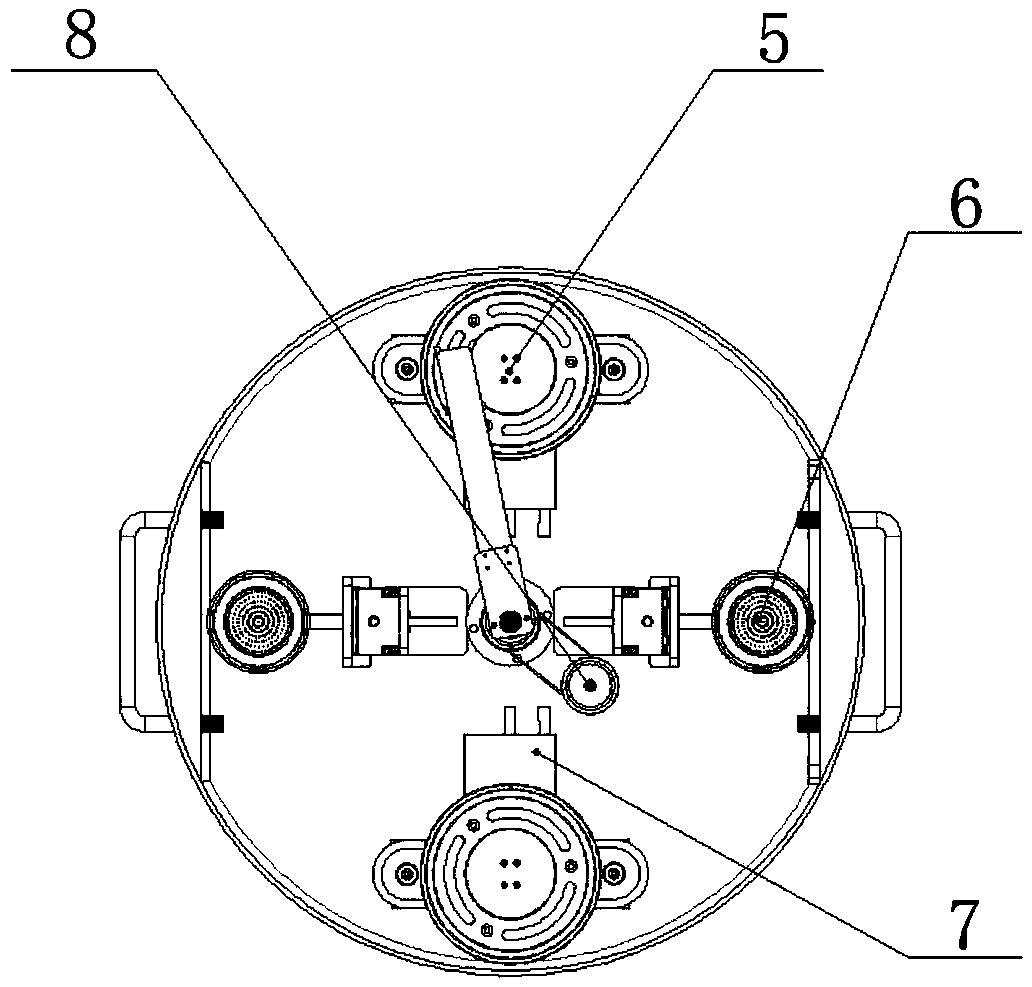

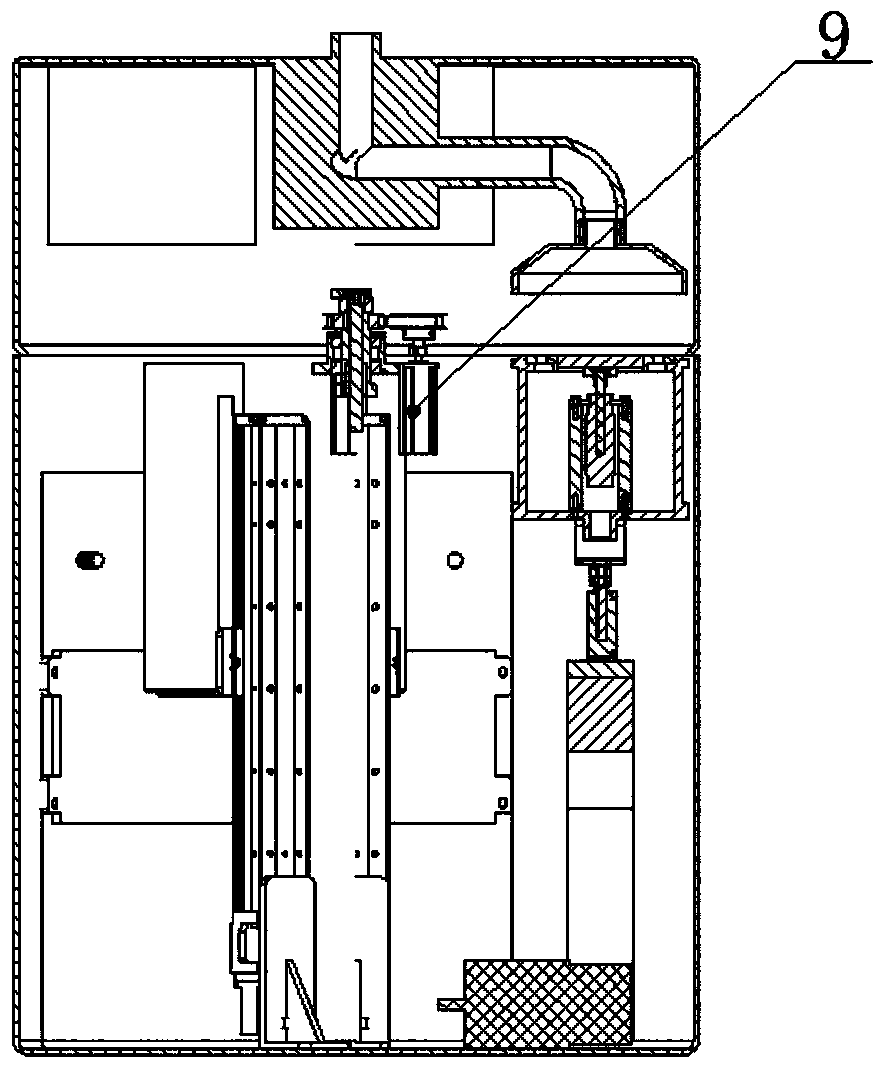

[0018] The structural composition and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. An automatic membrane-changing air particle sampler capable of collecting comparison samples, comprising an upper shell assembly 1, a lower shell assembly 4, a warehouse-moving manipulator assembly 8, a sampling assembly 5, and a filter membrane storage lift assembly 6, characterized in that: The moving manipulator assembly 8 , the sampling assembly 5 and the filter membrane storage lifting assembly 6 are installed on the lower housing assembly 4 , and the upper housing assembly 1 and the lower housing assembly 4 are fixed together by threads.

[0019] The filter membrane storage and lifting assembly 6 includes a linear module fixing frame 10, a servo motor 11, an elastic coupling 12, a linear module 13, a lift frame 14, a filter membrane clamp assembly 15 and a filter membrane clamp st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com