An installation device and installation method for d-shaped bolts in a blind cavity of a rotating part

A bolt installation method and a technology for installation devices, which are applied in the manufacture of tools, hand-held tools, etc., and can solve problems such as damage to the stop surface of the body of the rotating body, loss of blocks, and hidden quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

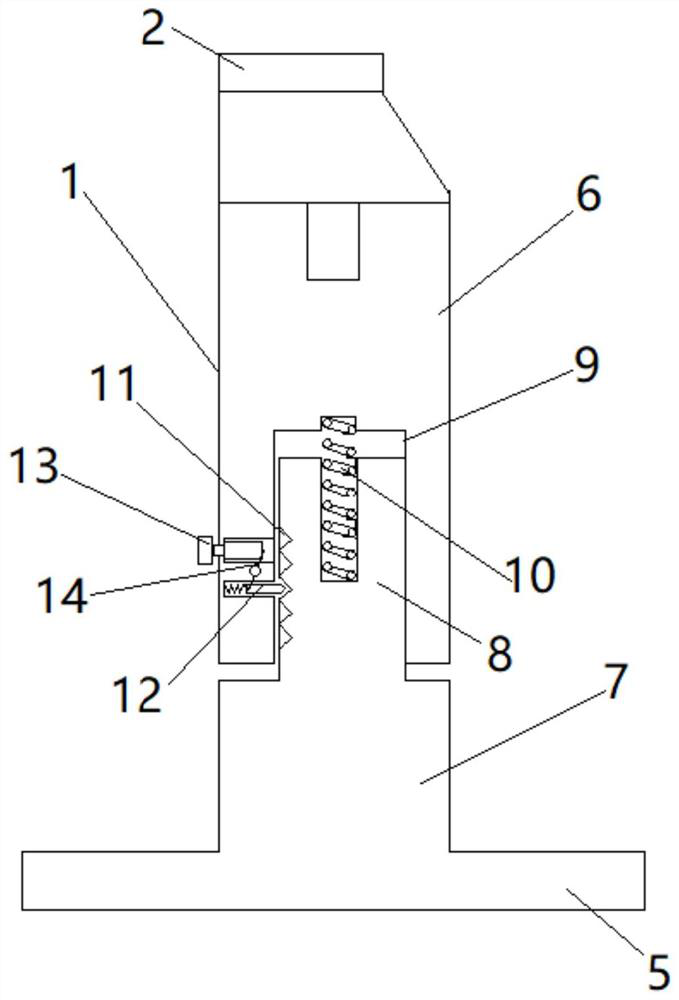

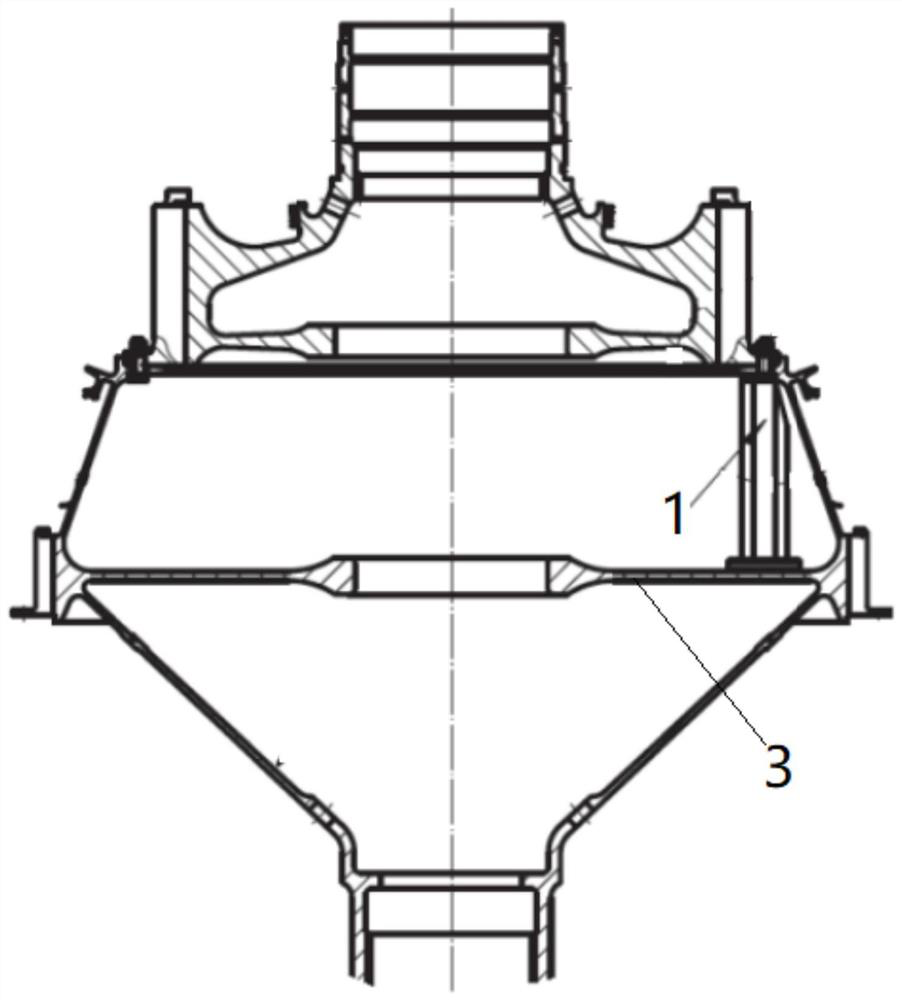

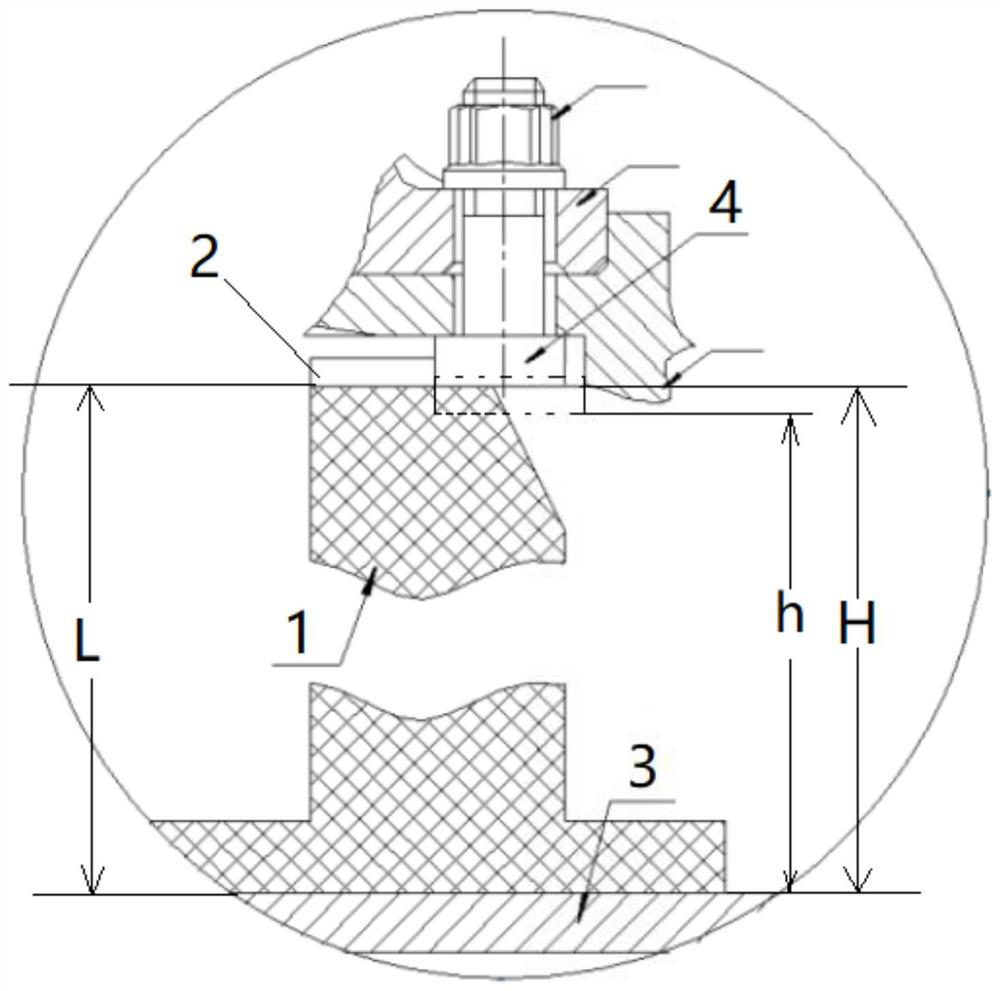

[0028] like Figure 1 to Figure 3 As shown, a D-shaped bolt installation device in the blind cavity of a rotating part includes a support adjustment column 1, and the upper end of the support adjustment column 1 is provided with a rectangular through slot 2, and the width of the rectangular through slot 2 is greater than the length of the straight side of the D-shaped bolt 4. During the process, the height from the bottom of the rectangular through groove 2 of the support adjustment column 1 to the bottom of the support adjustment column 1 is not less than the end surface of the head of the D-bolt 4 to the web plate of the rotating body disc 3 when the minimum contact surface of the D-bolt 4 contacts the stop surface the distance;

[0029] Specifically, during the support process, the length from the bottom of the rectangular through groove 2 of the support adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com