Fabricated building outer wall construction operation device

A kind of building exterior wall, prefabricated technology, applied in the direction of building, building structure, house structure support, etc., can solve the problem of high labor intensity of artificial pulling, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] Example 1

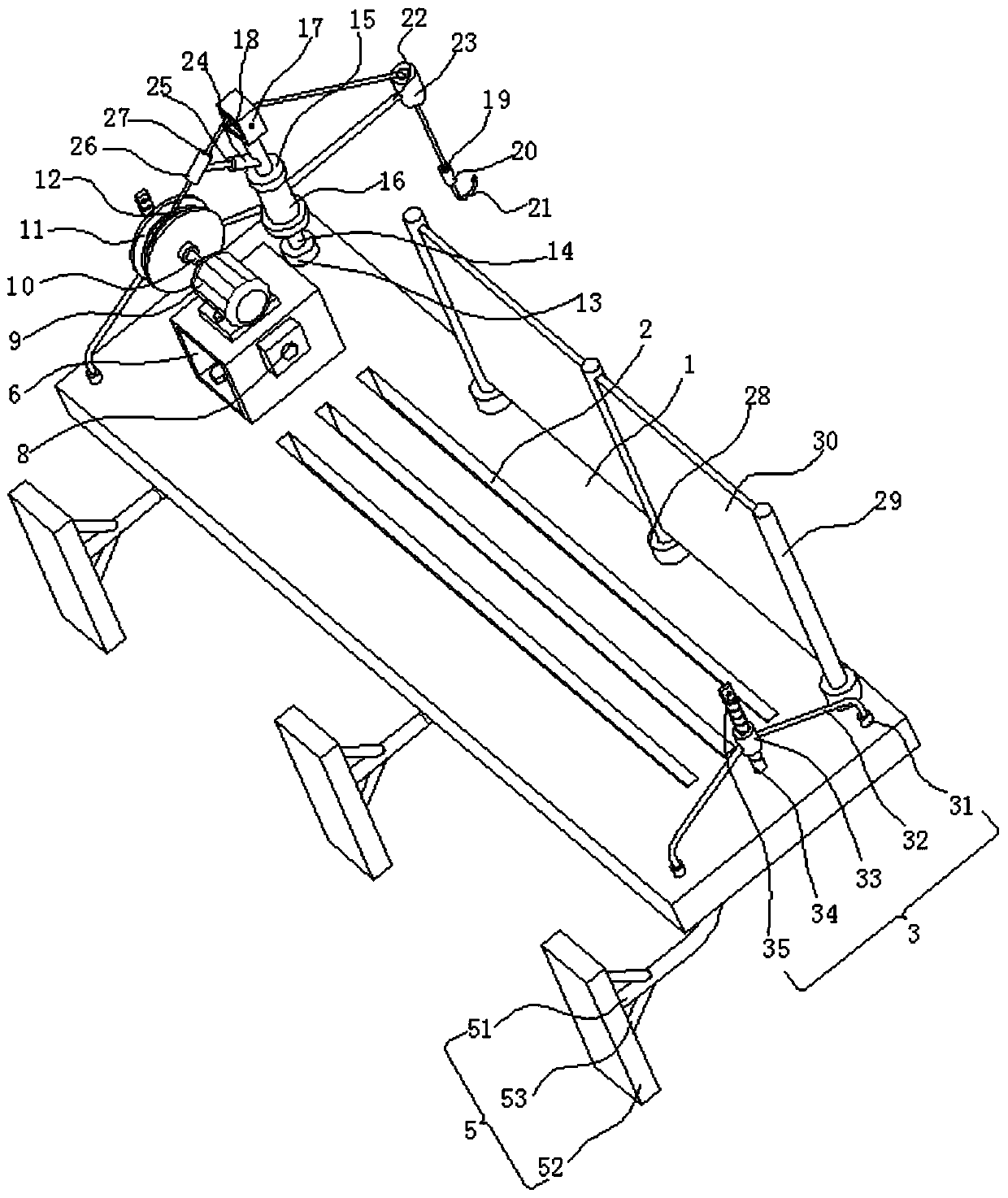

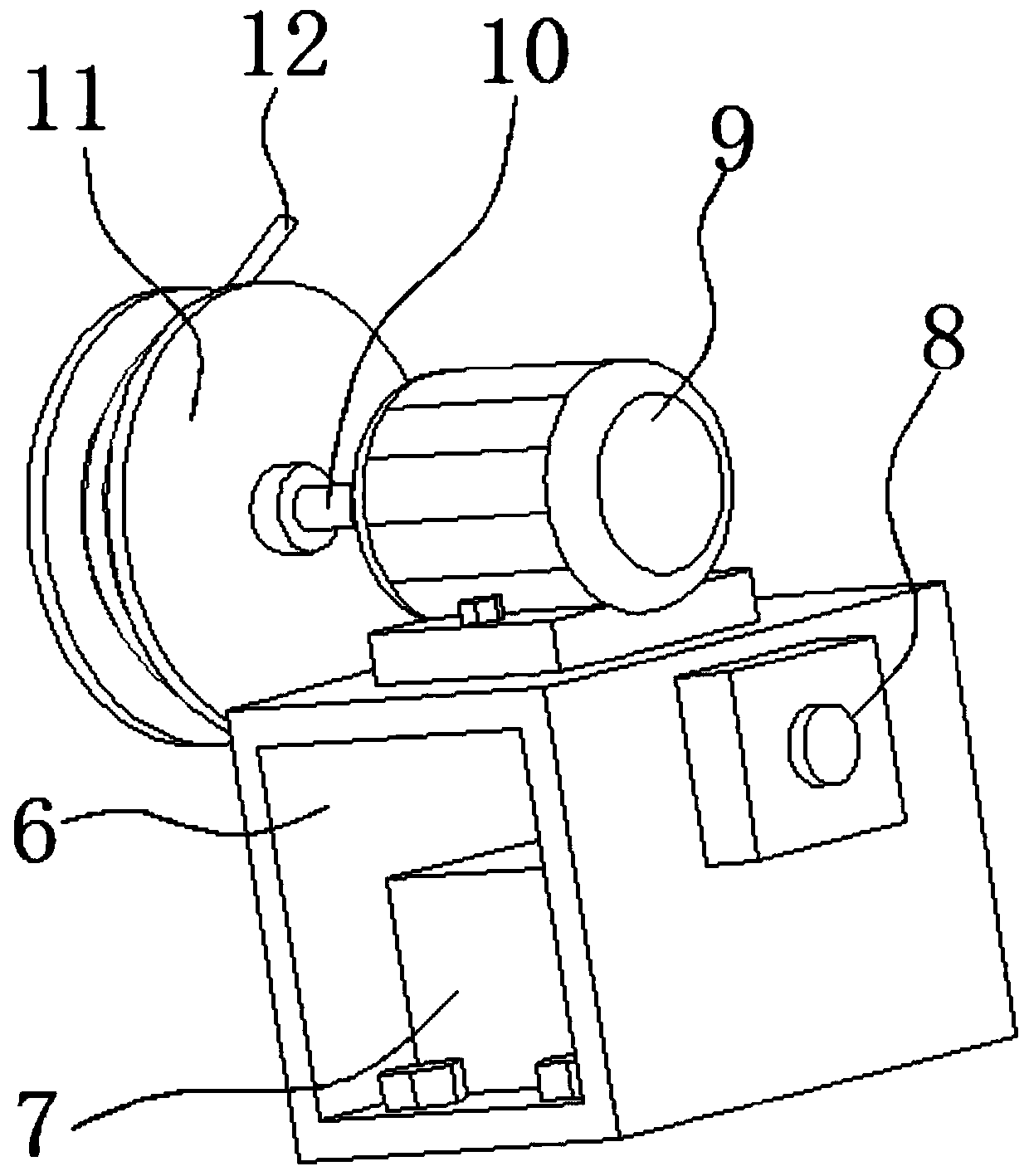

[0023] refer to Figure 1-4 , an assembly type building exterior wall construction operation device, including a support plate 1, a plurality of strip holes 2 are opened on the support plate 1, and the function of the strip holes 2 is to facilitate the discharge of the sundries on the support plate 1, and the support plate The upper end of 1 is fixedly connected with a connecting frame on both sides. The function of the connecting frame is to connect with the external pulling mechanism to control the height of the support plate 1. The bottom end of the support plate 1 is fixedly connected with a number of second fixing seats 4. Supporting feet 5 are fixedly connected to each of the second fixing bases 4 . The function of the supporting feet 5 is to contact the wall, so that the support plate 1 will not tip over. The upper end of the support plate 1 is fixedly connected with a first fixing frame 6 .

[0024] A battery block 7 is fixedly connected in the firs...

Example Embodiment

[0027] Example 2

[0028] refer to figure 1 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the connecting frame includes two first fixing bases 31 , the function of the first fixing bases 31 is to fix the first fixing rod 32 , and each first fixing base 31 are fixedly connected with a first fixing rod 32, one end of each first fixing rod 32 is fixedly connected with a threaded sleeve 33, the function of the threaded sleeve 33 is to connect the threaded rod 34, and the threaded rod 34 is connected to the threaded sleeve 33, The upper end of the threaded rod 34 is provided with a through hole 35, and the function of the through hole 35 is to connect an external pulling device.

Example Embodiment

[0029] Example 3

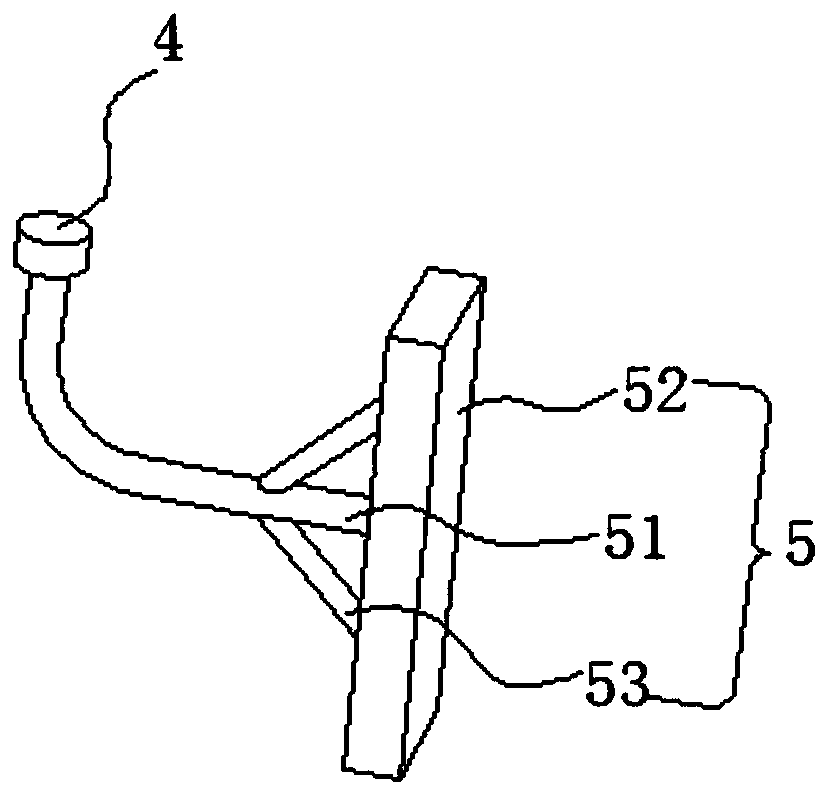

[0030] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the support foot 5 includes a second fixing rod 51, the second fixing rod 51 is connected to the second fixing seat 4, and one end of the second fixing rod 51 is fixedly connected There is a fixed plate 52, the function of the fixed plate 52 is to contact the wall to prevent the support plate 1 from overturning, the fixed plate 52 is connected with a reinforcing rod 53, and one end of the reinforcing rod 53 is connected to the second fixed rod 51.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com