A Bowl Head Hanging Board Facilitating Automatic Defect Identification

A technology of automatic identification and bowl-head hanging board, which is applied in the direction of optical testing flaws/defects, cable installation, overhead installation, etc., can solve the problems of not considering the degree of wear and inconvenient automatic defect identification, so as to avoid accidental falling off and reduce Deformation, the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

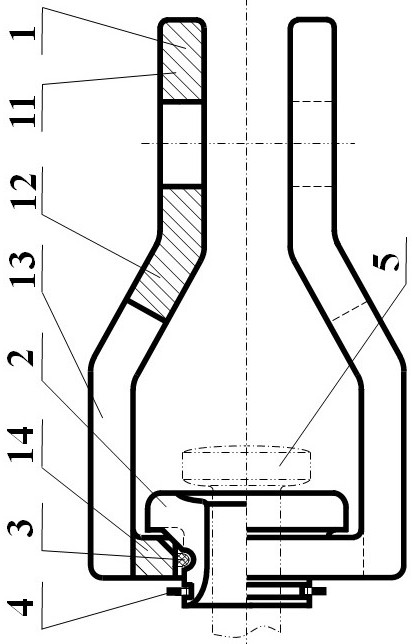

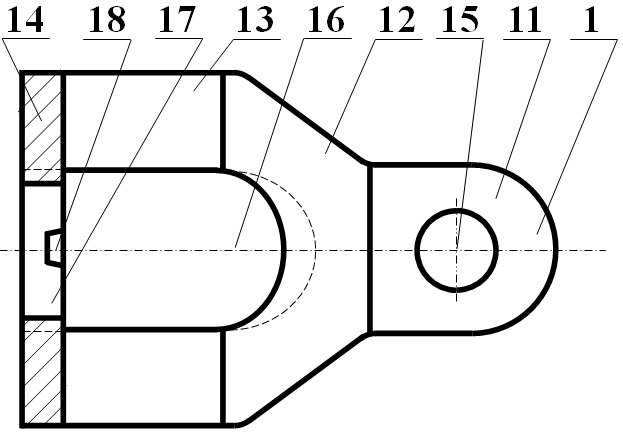

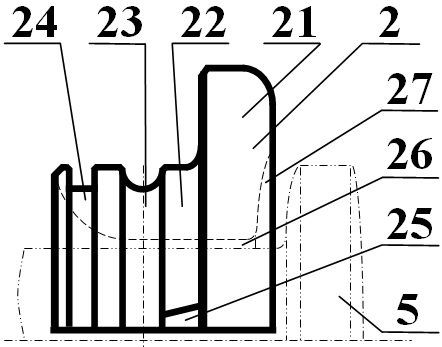

[0052] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is the front view of the bowl head hanging plate of the present invention, including the hanging plate 1, the bowl cover 2, the O-ring 3 and the retaining spring 4; figure 2 for peg board 1 in figure 1 A top view of the location.

[0053] The hanging plate 1 is a symmetrical frame-shaped curved plate, including an orifice plate 11, a folded plate 12, a fence 13 and a bottom plate 14. There is a transverse through hole 15 in the middle of the orifice plate 11, and a horizontal through hole 15 in the middle of the folded plate 12. There is a through groove 16 that runs through the fence 13 longitudinally, and there is a longitudinal sleeve hole 17 in the center of the bottom plate 14, and there are inclined grooves 18 on the upper and lower sides of the sleeve hole 17.

[0054] The orifice 11 is a longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com