Colour change system for powder coating

A powder coating and powder technology, applied in the field of color change system, can solve the problems of time-consuming cleaning operation, increase the complexity and cost of coating equipment, and achieve the effect of reducing operation downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

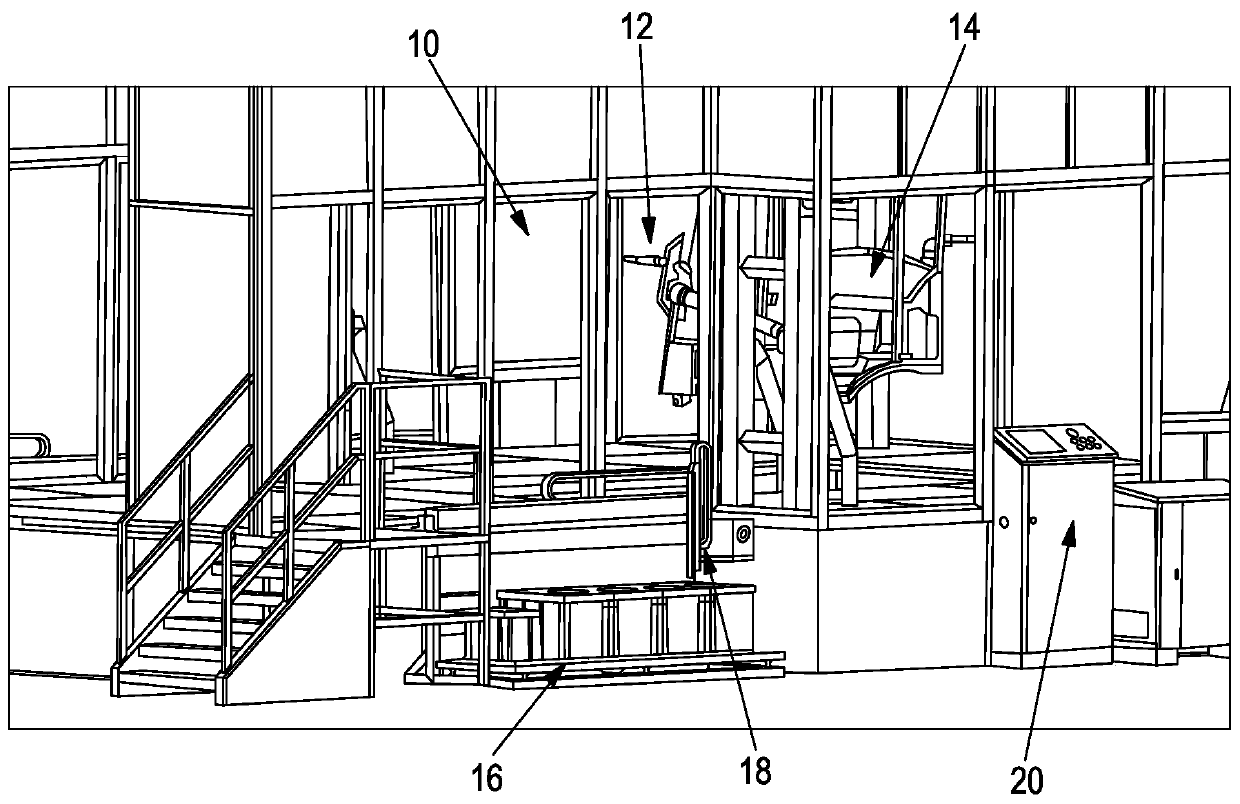

[0021] refer to figure 1 , which shows a powder coating plant with a coating chamber 10, inside the coating chamber 10 is a robot-operated powder spray coating device 12 for applying paint to a component 14, which may be, for example, a vehicle body part. Powder is supplied from the powder unit 16 to the coating device 12 by means of a suction unit 18 through a conduit (not shown). The powder unit 16 and the suction unit 18 are suitable as a color changing system, which will be referred to below figure 2 to Figure 4 for a more detailed description. like figure 1 As shown, a controller 20 controls the operation of the powder coating apparatus.

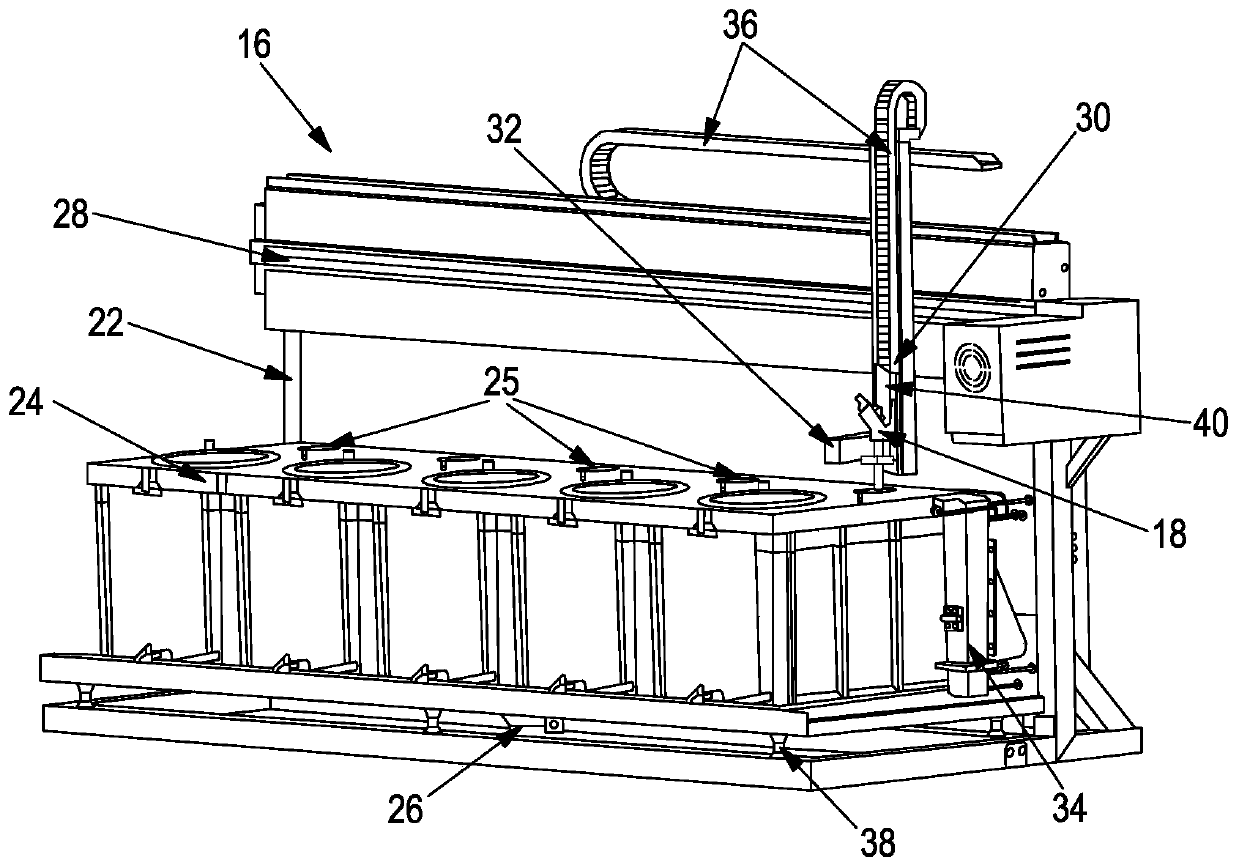

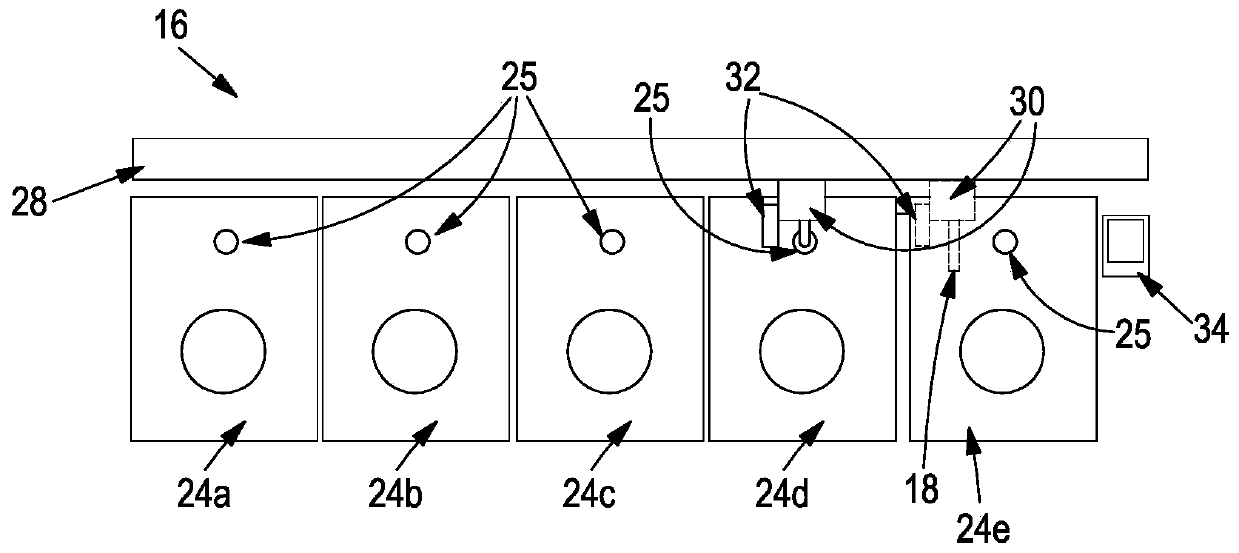

[0022] figure 2 A powder unit 16 and a suction unit 18 forming an embodiment of the color change system are shown. Frame 22 supports a plurality of powder containers 24 in the form of a row of fluid tanks filled with powder, each container 24 holding a powder of a different color ( figure 2 Five such containers are shown in , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com