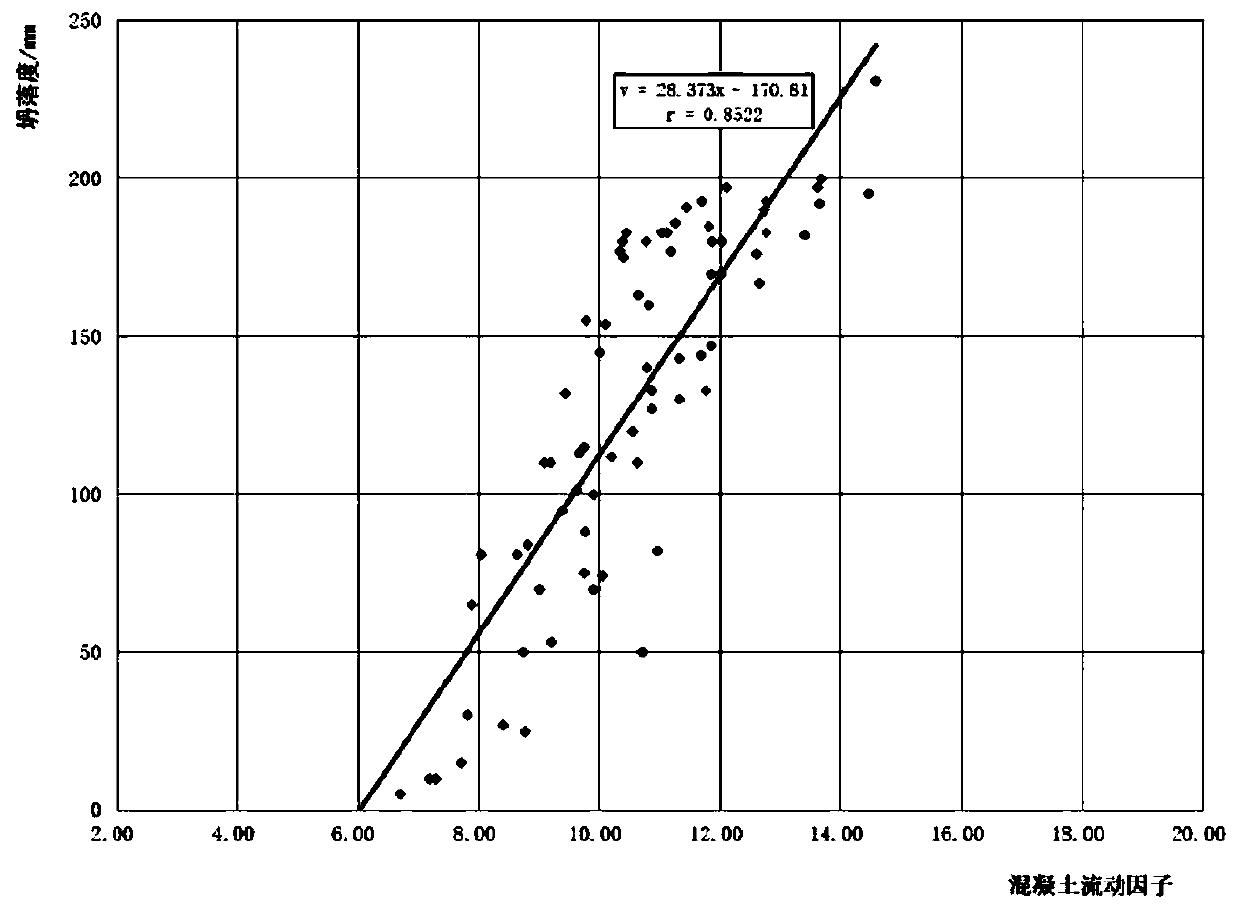

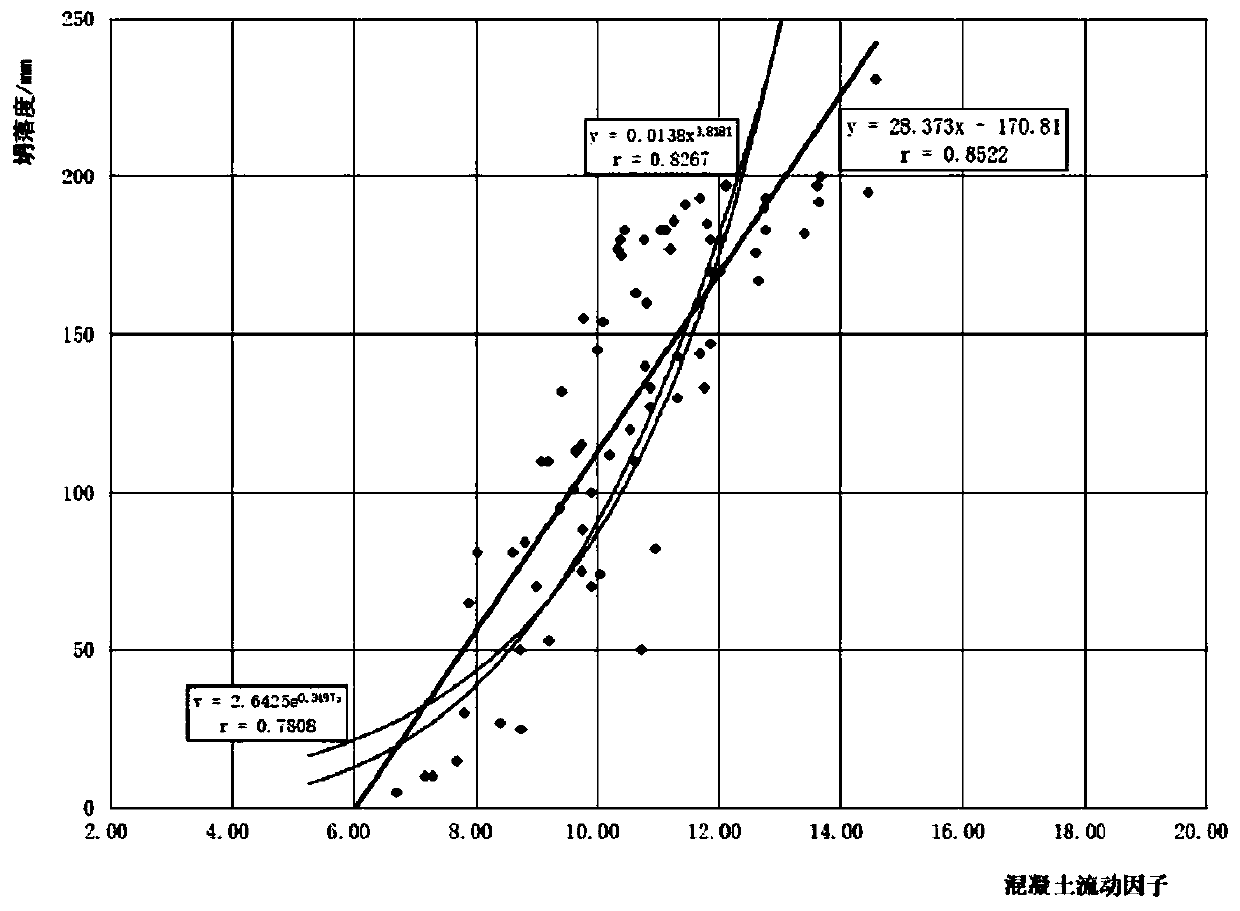

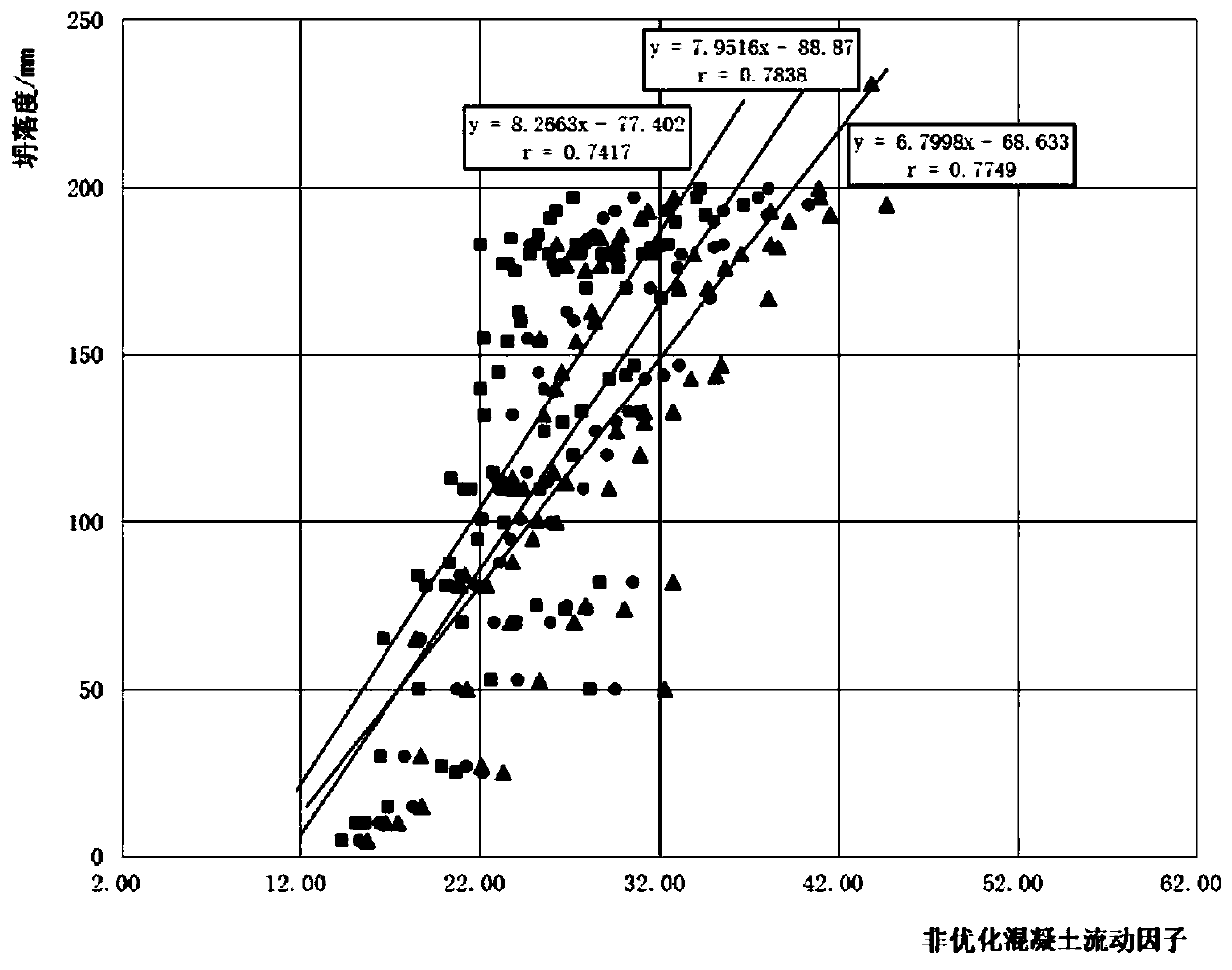

Concrete slump inference method based on mix proportion and raw material performance

A mix ratio, concrete technology, applied in the direction of analyzing materials, material inspection products, measuring devices, etc., can solve problems such as large differences in porosity, and achieve the effect of high accuracy, strong certainty, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 Infer the slump according to the concrete mix ratio and raw material properties, and conduct a mix ratio review

[0059] Given a concrete mix ratio, the amount of various materials per cubic meter of concrete and the test results of raw material properties are as follows:

[0060] 149kg of water, 356kg of cement, 883kg of sand, 438kg of small stones, 656kg of medium stones, and 2.848kg of water reducing agent, the amount of sand and stone is the amount in the air-dried state;

[0061] Cement: Density 3060kg / m 3 ;

[0062] Sand: apparent density 2640kg / m 3 , loose bulk density 1560kg / m 3 ;

[0063] Stone: maximum particle size 40mm, apparent density 2800kg / m 3 , the combined loose bulk density is 1526kg / m 3 ;

[0064] Water reducing agent: dosage 0.8%, water reducing rate 36%;

[0065] Fluidity of glue: 400mm.

[0066] Infer slump as follows:

[0067] 1) Calculation of sand surplus coefficient (F s )

[0068] Amount of sand per square concrete M s ...

Embodiment 2

[0096] Example 2 According to the requirements of concrete slump and raw material performance, the water consumption is reversely calculated to guide the design of mix ratio

[0097] In a concrete mix design, the slump is required to be 50mm to 70mm, the water-cement ratio is selected as 0.34, the sand ratio is selected as 27%, the air content is 3.0%, and the sand and stone are in a saturated surface-dry state.

[0098] Cement: Density 3200kg / m 3 ;

[0099] Fly ash: density 2410kg / m 3 , the amount of fly ash is 15%;

[0100] Sand: apparent density 2680kg / m 3, loose bulk density 1560kg / m 3 , water absorption 0.9%;

[0101] Stone: maximum particle size 40mm, apparent density 2690kg / m 3 , combined loose bulk density 1740kg / m 3 , water absorption 0.2%;

[0102] Water reducing agent: dosage 0.8%, water reducing rate 20%;

[0103] Fluidity of glue: 150mm.

[0104] Follow the steps below to calculate water consumption:

[0105] 1) Inverse calculation of concrete flow fact...

Embodiment 3

[0152] Example 3 Adjust the existing mix ratio according to the changes in the properties of concrete raw materials

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com