Transport system

A handling system and technology of the handling department, applied in the field of robotics, can solve problems such as labor costs and low robot work efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In the following description, the same reference numerals are given to the same components, and repeated descriptions are omitted. In addition, the drawings are only schematic diagrams, and the ratio of dimensions between components, the shape of components, and the like may be different from the actual ones.

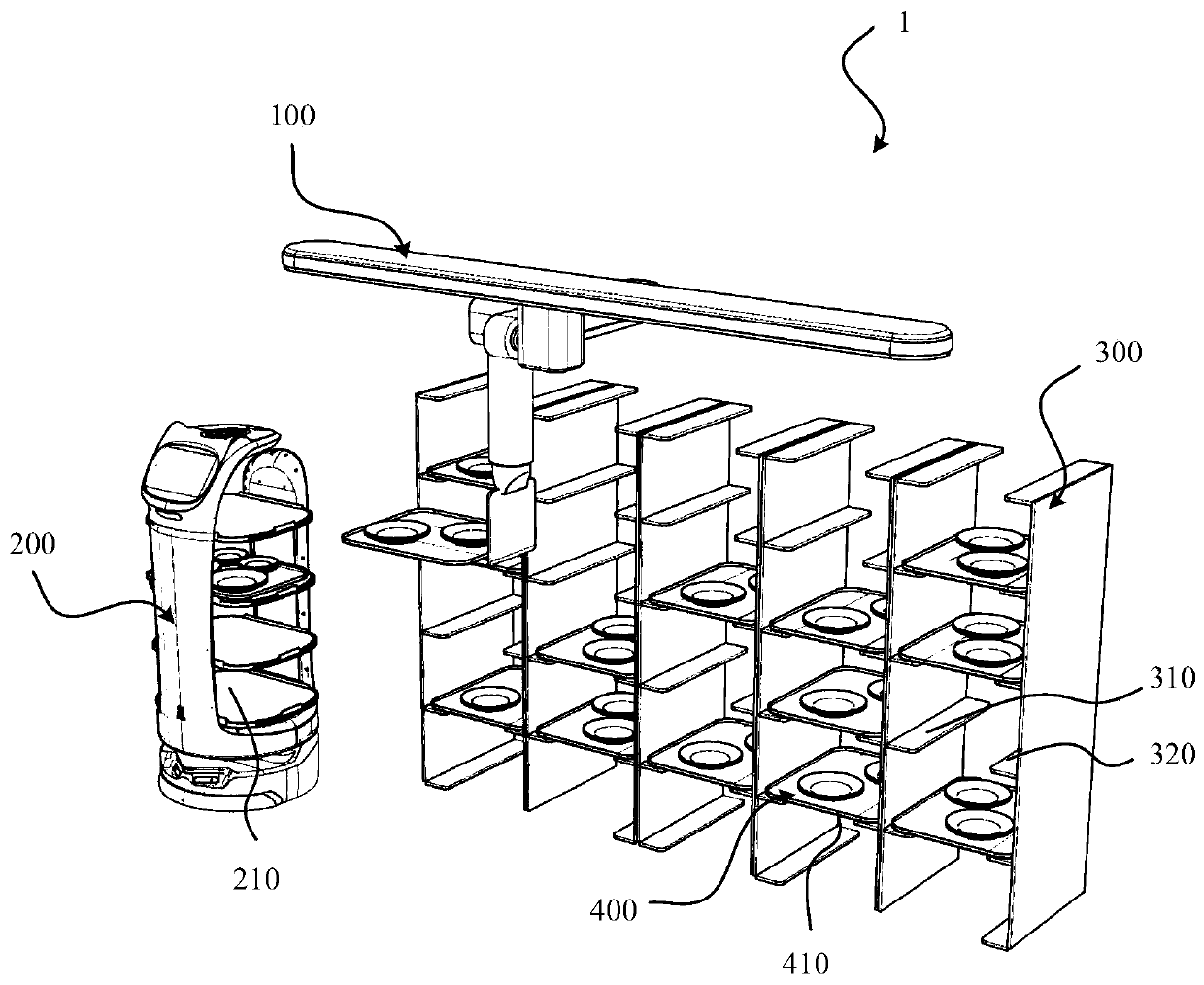

[0033] like Figure 1 to Figure 3 As shown, the embodiment of the present invention relates to a handling system 1 . The handling system 1 can be applied to the back kitchen of a restaurant.

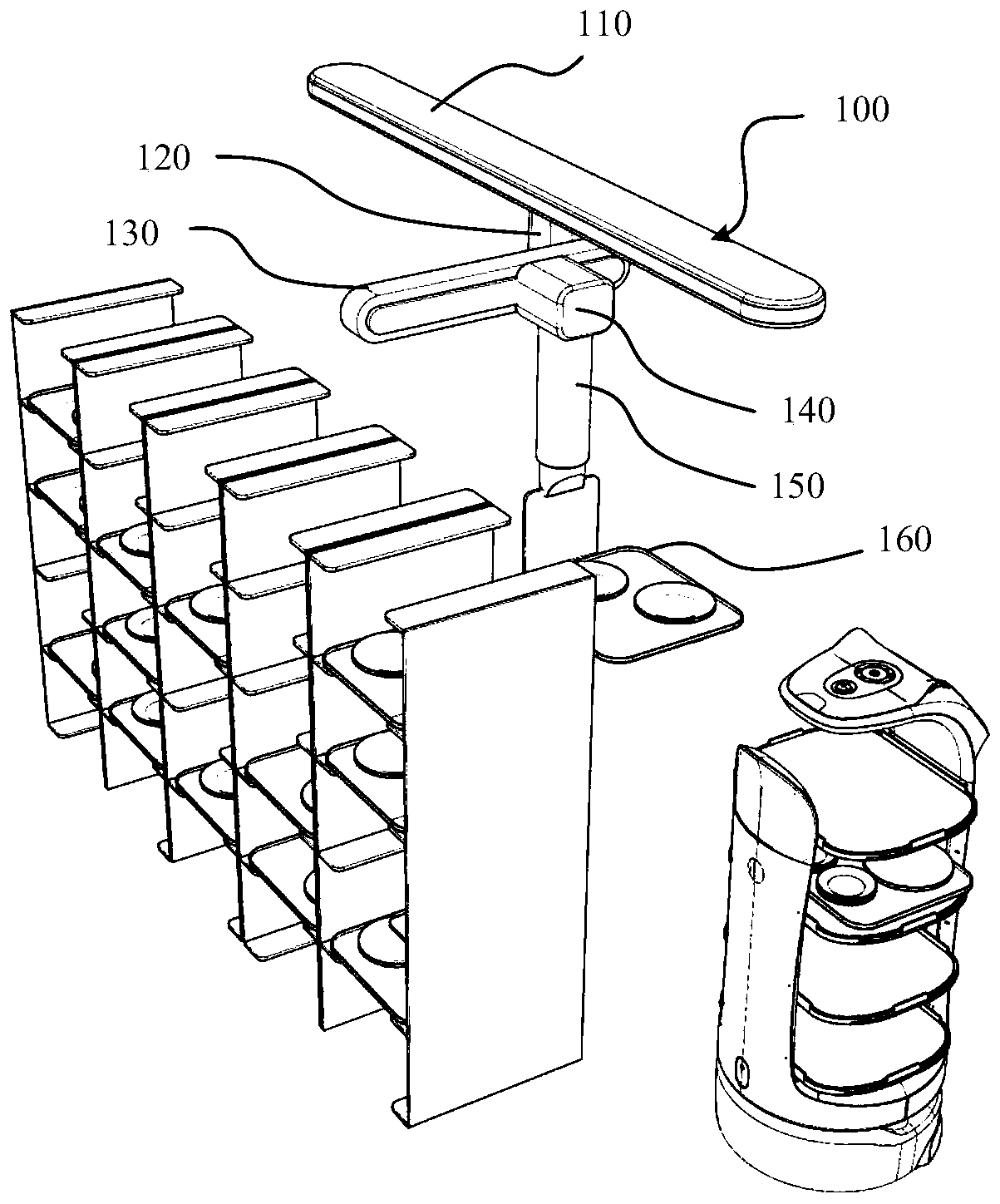

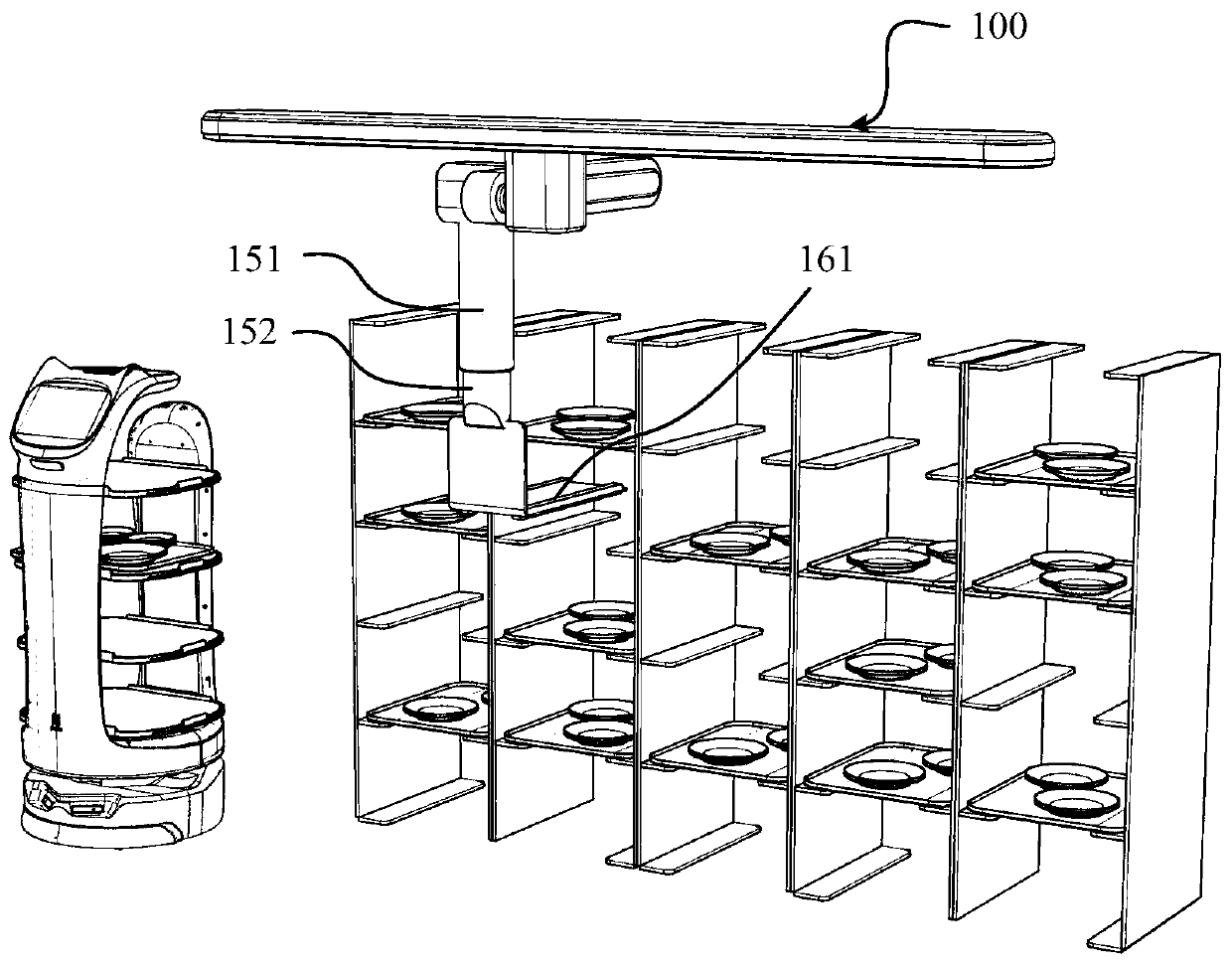

[0034] In this embodiment, the transport system 1 includes a transport mechanism 100 , a robot 200 and a rack 300 . The transport mechanism 100 includes a fixed part 110 , a first moving part 120 , a track mechanism 130 , a second moving part 140 , a transport part 150 and a carrying part 160 . The fixing part 110 is provided with a first track (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com