Auxiliary type wrench

A wrench and handle technology, applied in the directions of wrenches, wrenches, screwdrivers, etc., can solve the problem of not supporting large-area rotation of the wrench, and achieve the effect of improving practicability and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

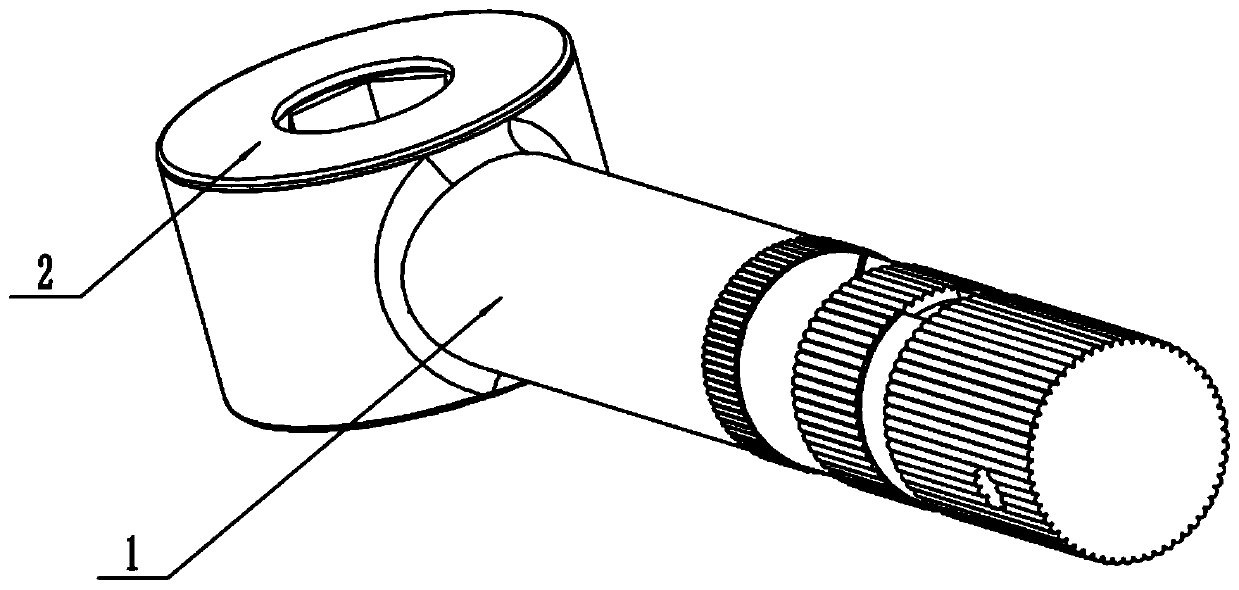

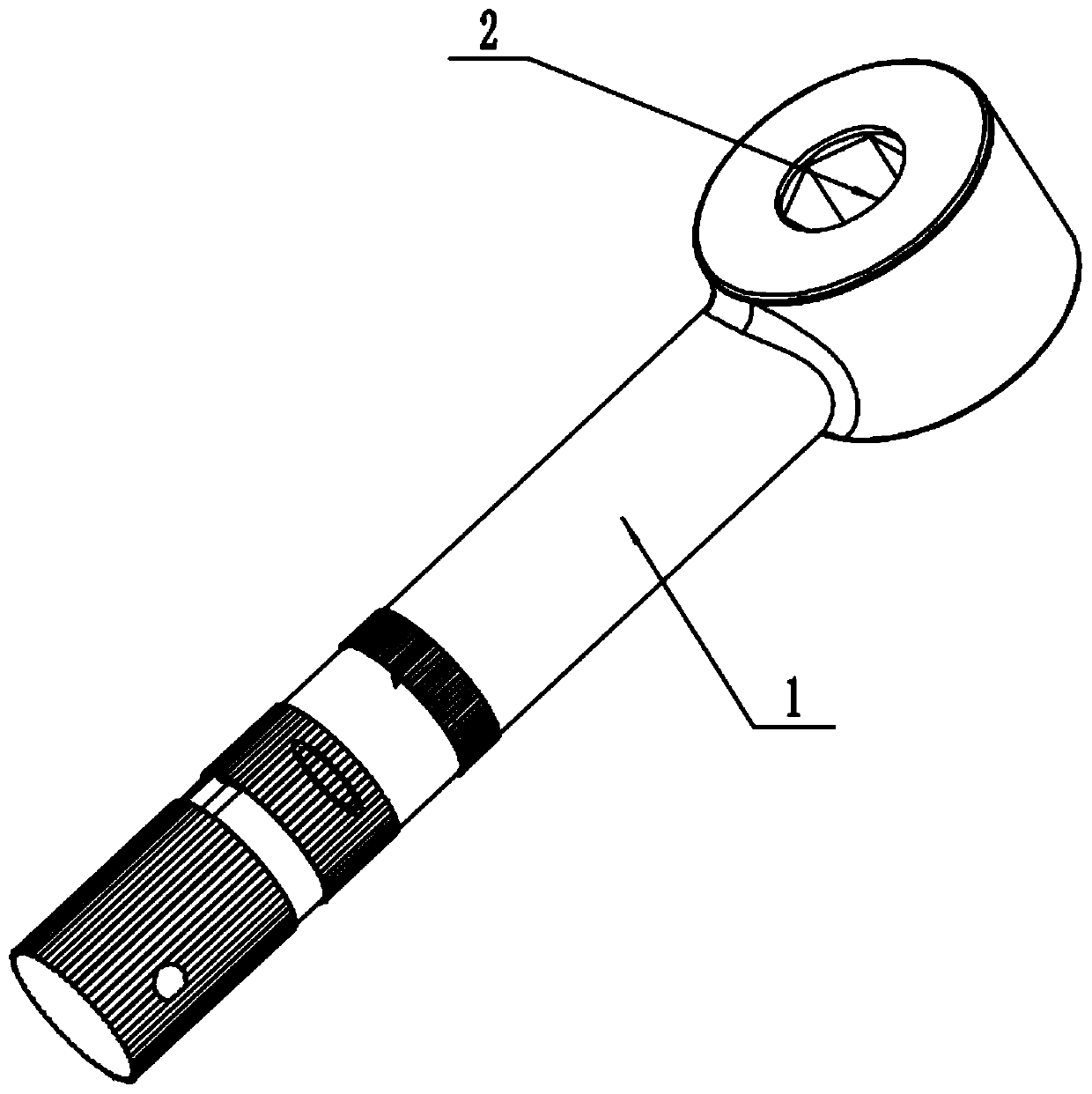

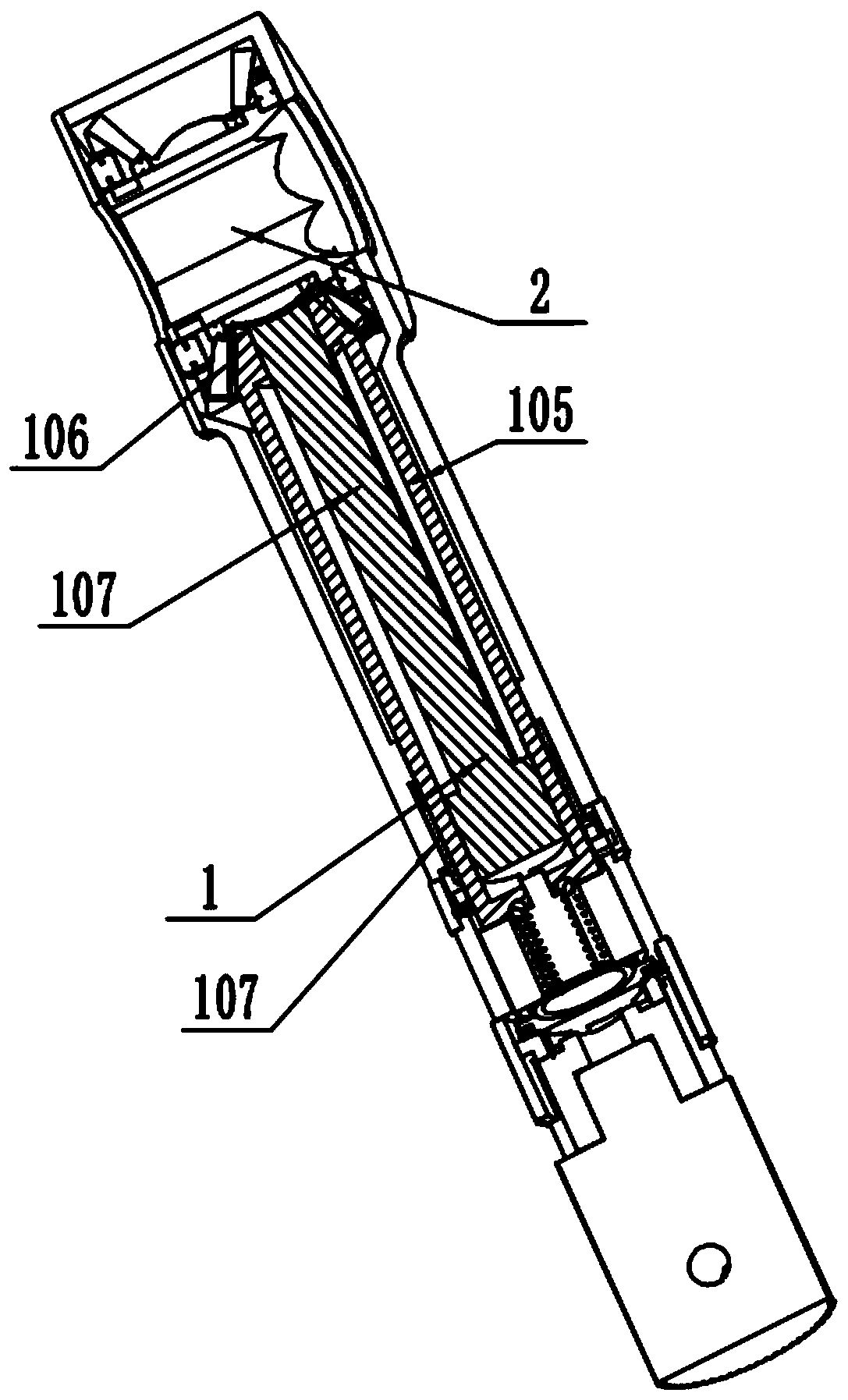

[0035] Examples, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 As shown, an auxiliary wrench is characterized in that it includes: a handle mechanism 1 and a rotating mechanism 2, and the rotating mechanism 2 is installed inside the handle mechanism 1;

[0036] The handle mechanism 1 includes a power transmission part, a mode switching part, a pre-tightening force application part and a handle 101, the power transmission part includes a driving bevel gear 106 and a transmission sleeve 105, and the driving bevel gear 106 and the transmission sleeve 105 is fixedly connected; the transmission sleeve 105 is connected with the pre-tightening force holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com