Suction assembly for endoscope and endoscope

An endoscope and component technology, applied in the field of endoscope, can solve the problems of unreliable rebound, large force, poor pressing feel, etc., and achieve the effects of reliable function, simple structure and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

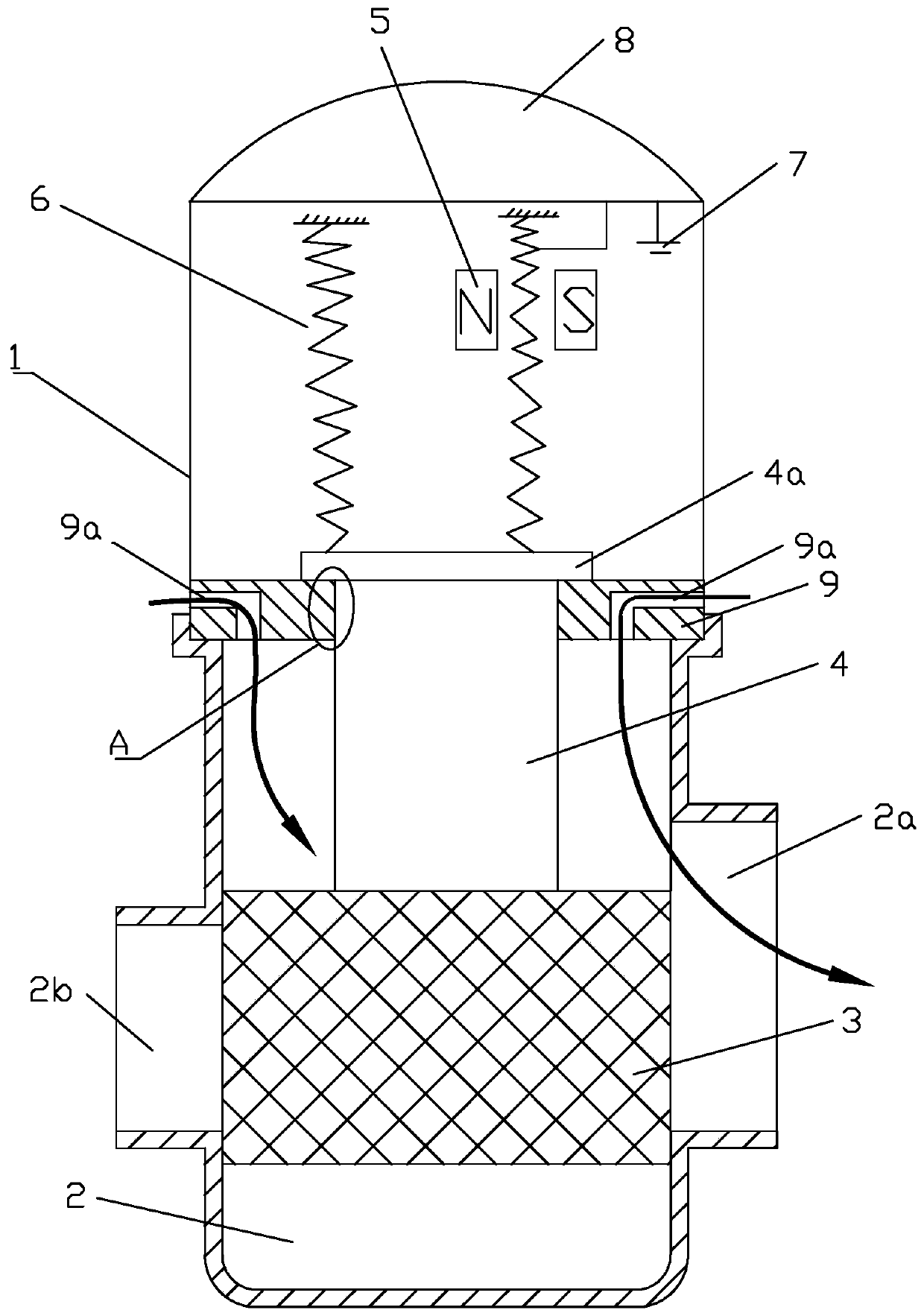

[0023] Example 1, see figure 1 , figure 2 , a suction assembly for an endoscope, including a button assembly 1 and a suction cavity 2, the suction cavity 2 is provided with a negative pressure port 2a and a suction port 2b; the button assembly 1 includes a valve core reset by a spring 6, The valve core slidably cooperates with the suction cavity 2 to connect or block the negative pressure port 2a and the suction port 2b; the button assembly 1 also includes a housing, and a valve stem 4 is arranged inside the housing, and the front end of the valve stem 4 is fixed A seal 3 is connected, and the seal 3 is located inside the suction cavity 2, and the seal 3 and the valve stem 4 constitute the valve core; the tail end of the valve stem 4 is connected with the spring 6, and a DC electromagnet assembly 5 is also arranged in the housing , the DC electromagnet assembly 5 forms a magnetic coupling with the valve stem 4; the DC electromagnet assembly 5 and the spring 6 are respectivel...

Embodiment 2

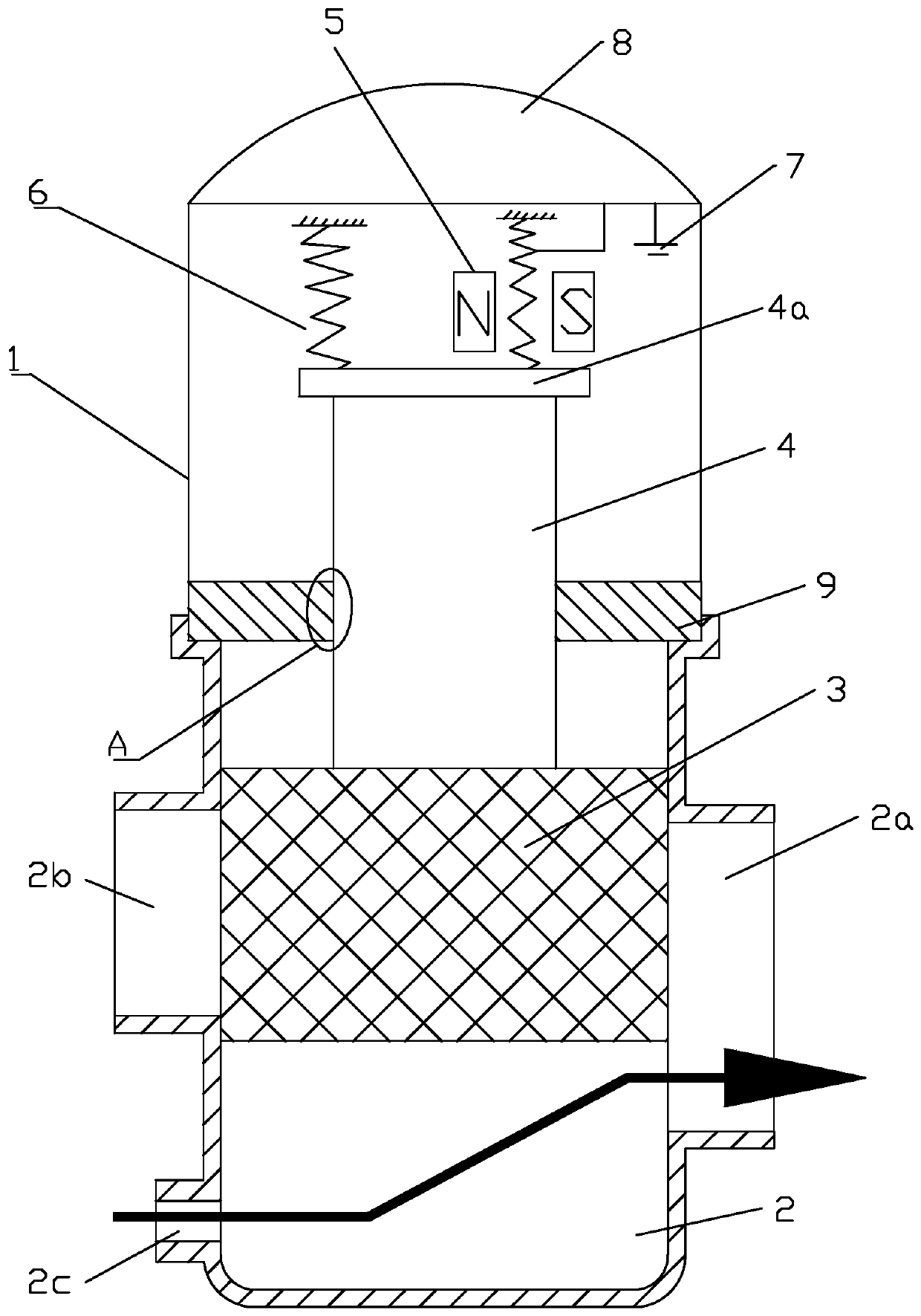

[0026] Example 2, see image 3 , Figure 4 , the spring 6 is a tension spring; the DC electromagnet assembly 5 drives the valve core to move in the direction of pulling the spring 6 after being energized. The suction cavity 2 is in an inverted convex shape, and the bottom or lower part of the cavity inside the suction cavity 2 protrudes downward. The air intake channel 2c communicates with the external atmosphere to replace the intake air provided on the stopper 9. aisle. Wherein, the negative pressure port 2a and the suction port 2b are arranged on the upper part of the suction cavity 2 .

[0027] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0028] Example 3, combined with Figure 1~4 , an endoscope, comprising the suction assembly of embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com