Soap film flowmeter

A flow meter, soap film technology, applied in the direction of volume measurement, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc., which can solve the problems of calculation flow interference, calculation trouble, data loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment is the condition of the standard condition (i.e. the standard condition): the temperature is 0°C (273.15k), the pressure is 101.325 kPa (1 standard atmospheric pressure, 760 mm Hg), and the upper port of the soap film tube receives the measured gas flow interface.

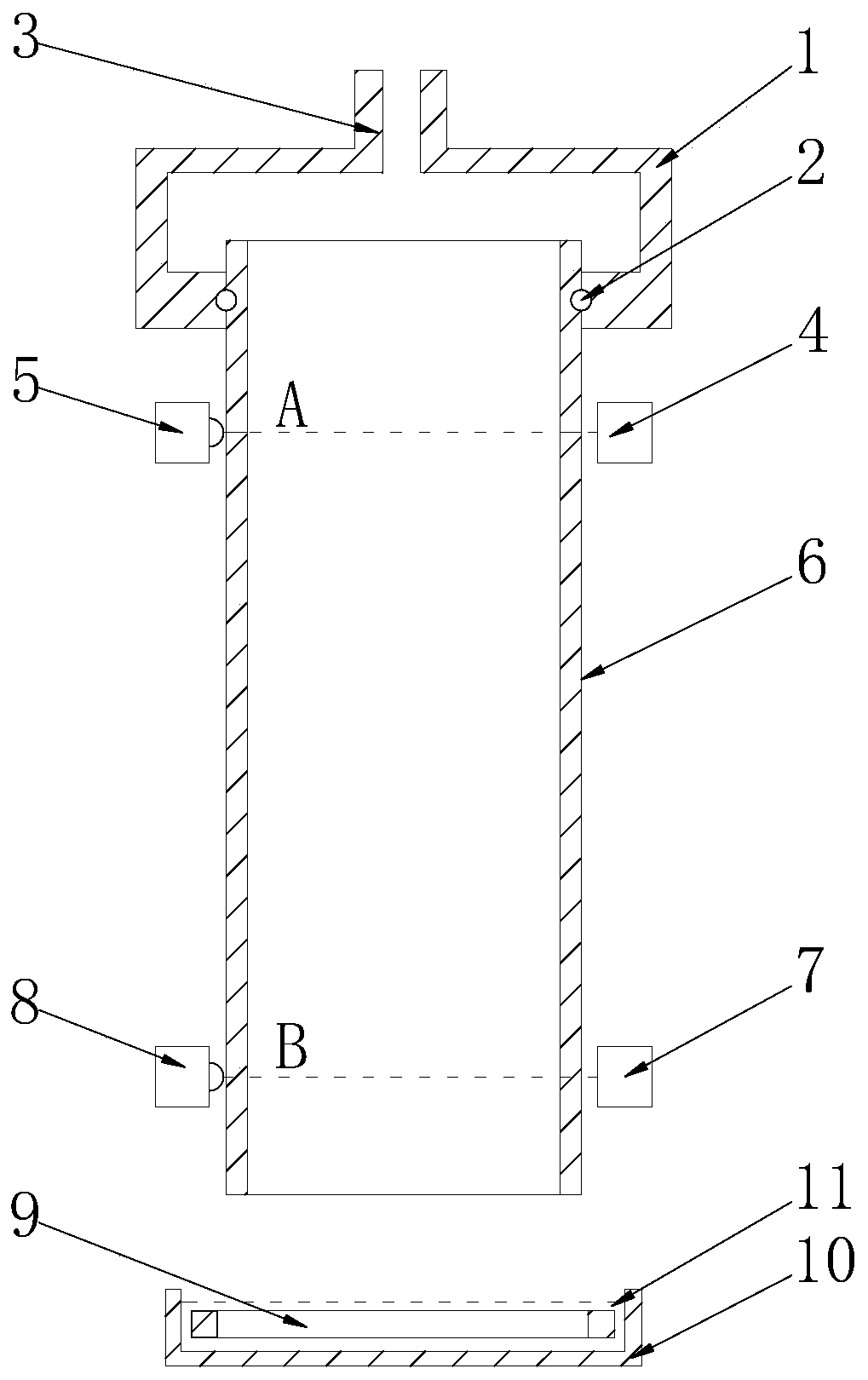

[0029] Such as figure 2 As shown, the soap film flowmeter is provided with a soap film tube 6, an upper infrared emitting tube 4 and an upper infrared receiving tube 5 arranged on the upper part of the outer wall of the soap film tube 6, a lower infrared emitting tube 7 and an upper infrared receiving tube arranged on the lower part of the outer wall of the soap film tube 6, and The lower infrared receiving tube 8, the soap liquid pool 11 and the film ring 9 arranged under the soap film tube 6, the film ring 9 inner diameter is not less than the outer diameter of the soap film tube 6, and the film ring 9 is connected with the film ring lifting device , The filming ring 9 is provided ...

Embodiment 2

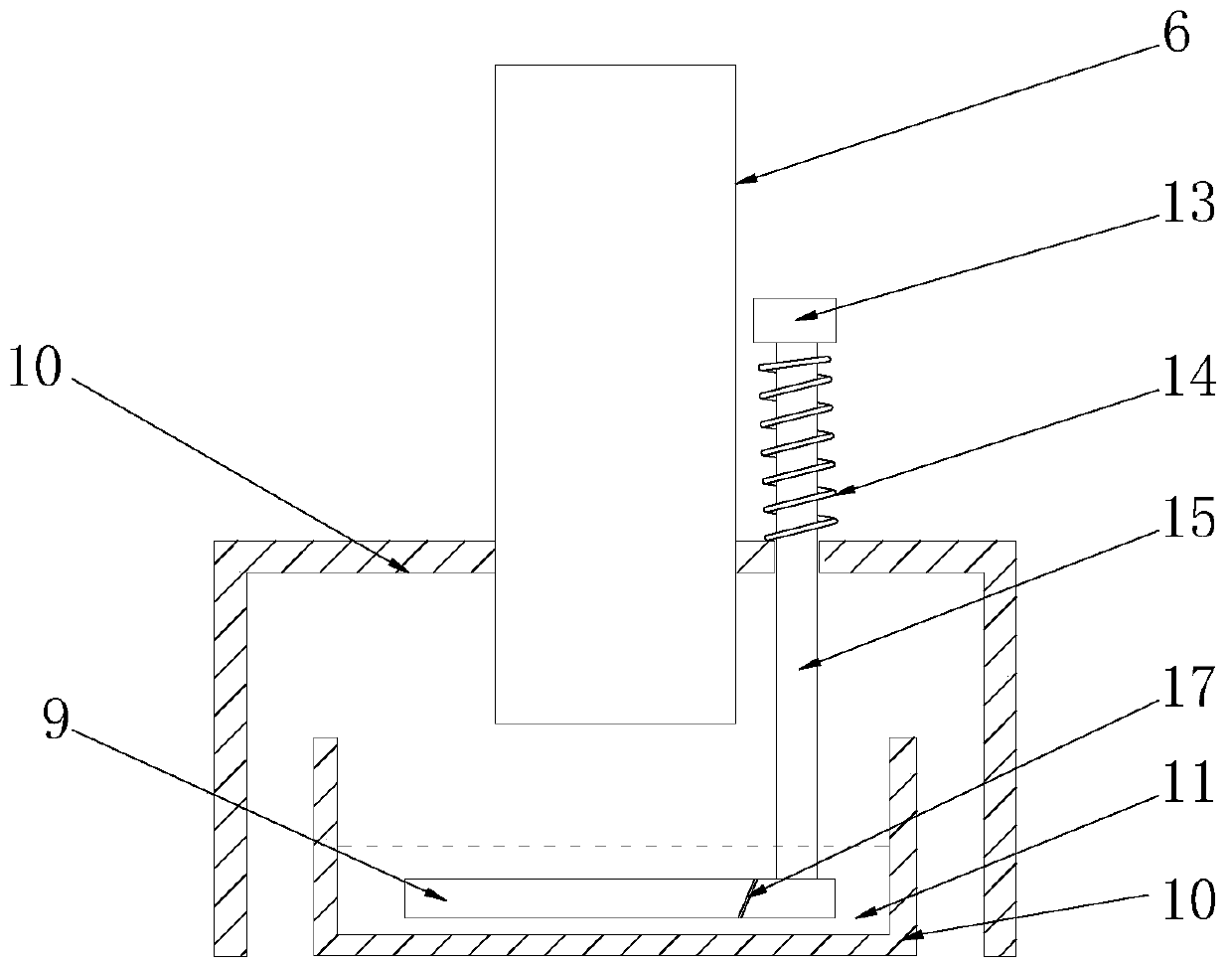

[0035] Such as image 3 with Figure 4 As shown, the film ring 9 has a slit 17, and the slit 17 direction is obliquely downward, and the slit 17 cuts off the film ring 9, and the soap film tube 6 outer wall is provided with a soap film tube support 12, and the slit 17 of the film ring 9 A membrane breaking post 16 is arranged on the soap film tube support 12 above. The rupture column 16 has a cylindrical structure. When the membrane rupture ring 9 moves below the membrane rupture column 16, the membrane rupture column 16 presses the membrane rupture ring 9 to give it a downward force. Exist, the film starting ring 9 cracks gradually increase, thereby tearing down the soap film. The film spring 14, the film pull bar 15 and the film button 13 are used as the film ring lifting device. The film pulling rod 15 passes through the film spring 14, and one end is connected with the film button 13, and the other end is connected with the film ring 9. The plane where the membrane rin...

Embodiment 3

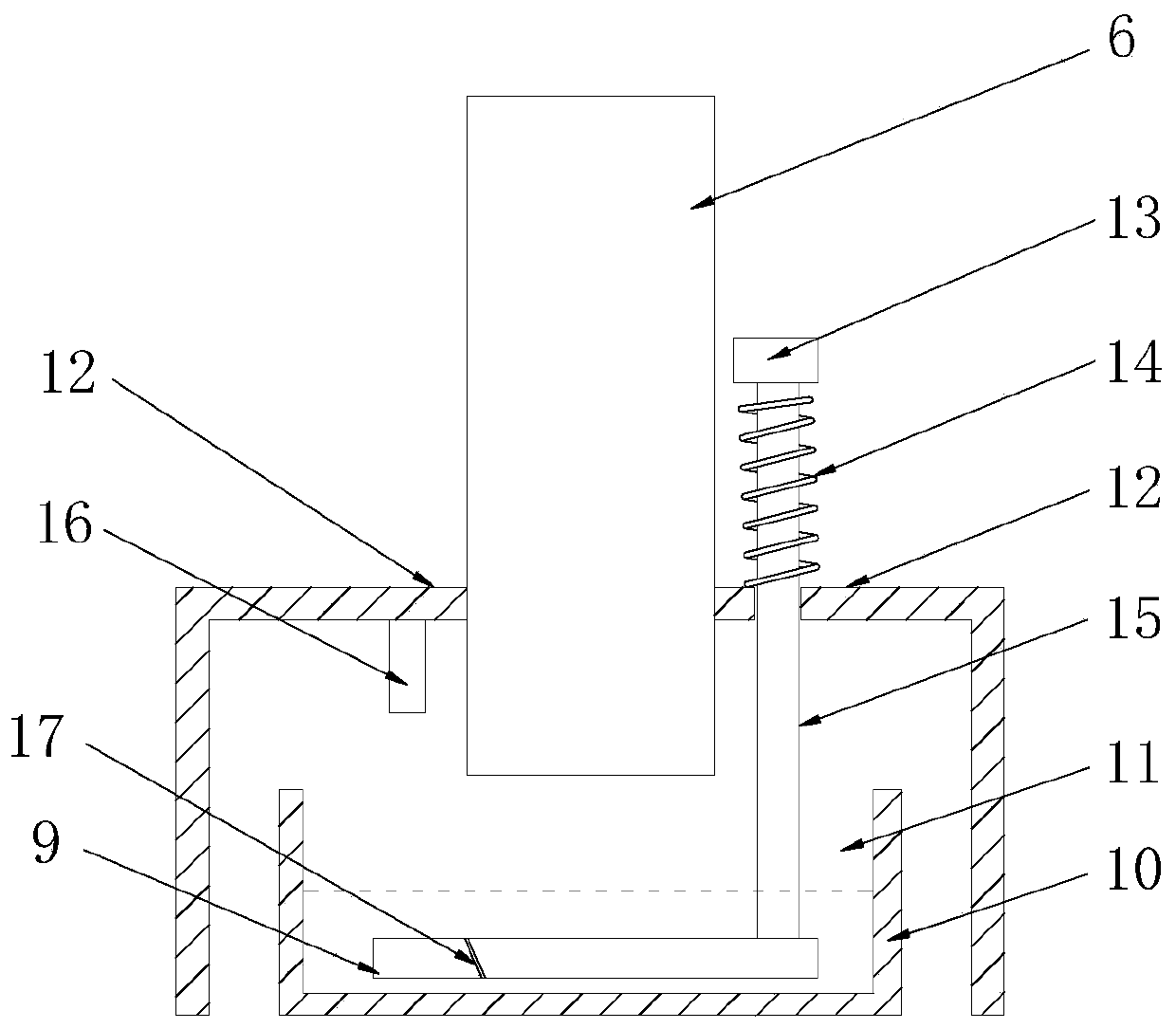

[0037] Such as Figure 5As shown, the film ring 9 has a slit 17, and the direction of the slit 17 is vertically downward, and the slit 17 cuts off the film ring 9, and the outer wall of the soap film tube 6 is provided with a soap film tube support 12, and at the slit 17 of the film ring 9 The upper soap film tube support 12 is provided with a membrane rupture column 16 . The rupture column 16 has a thick upper and narrower structure. When the membrane rupture ring 9 moves below the membrane rupture column 16, the narrow opening of the membrane rupture column 16 enters the membrane rupture ring 9. As the membrane rupture ring 9 continues to move upward, the rupture The membrane column 16 gradually becomes thicker, and the membrane rupture column 16 gives an outward support force to the membrane ring 9, and because of the existence of the crack 17 on the membrane ring 9, the cracks in the membrane ring 9 gradually increase, thereby tearing outward soap film. The film spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com